Double-effect flue gas purification apparatus and purification method thereof

A flue gas purification and flue gas technology, used in chemical instruments and methods, separation methods, perfluorocarbon/hydrofluorocarbon capture, etc., can solve the problem that the spray tower cannot meet the requirements and the anti-corrosion layer on the tower wall is easy to fall off. , enterprises increase operating costs and other issues, to avoid operational errors, improve market competitiveness, and increase the control range of slurry concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] The present invention will be further described below in conjunction with accompanying drawing, and the structure and principle of this device are very clear to those skilled in the art. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

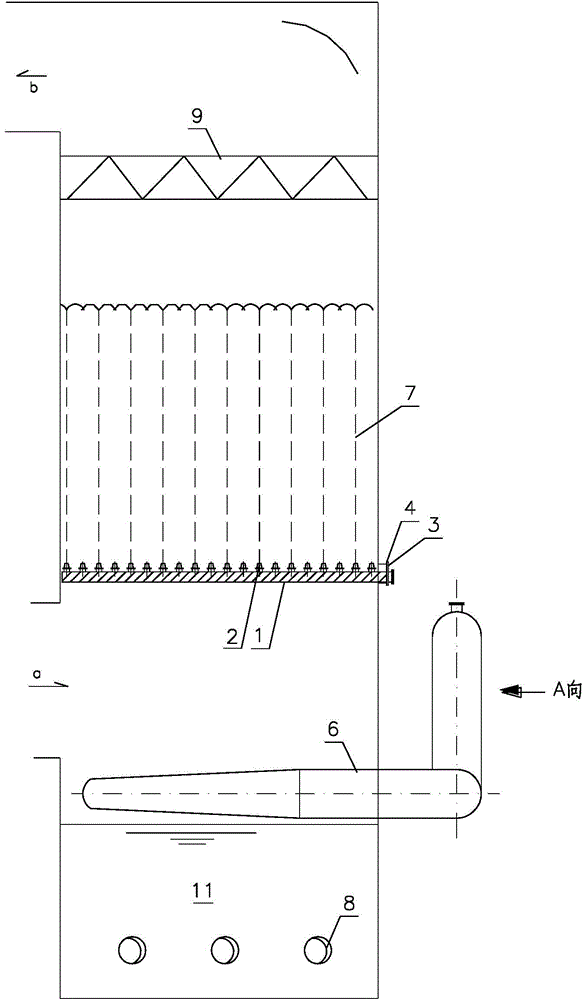

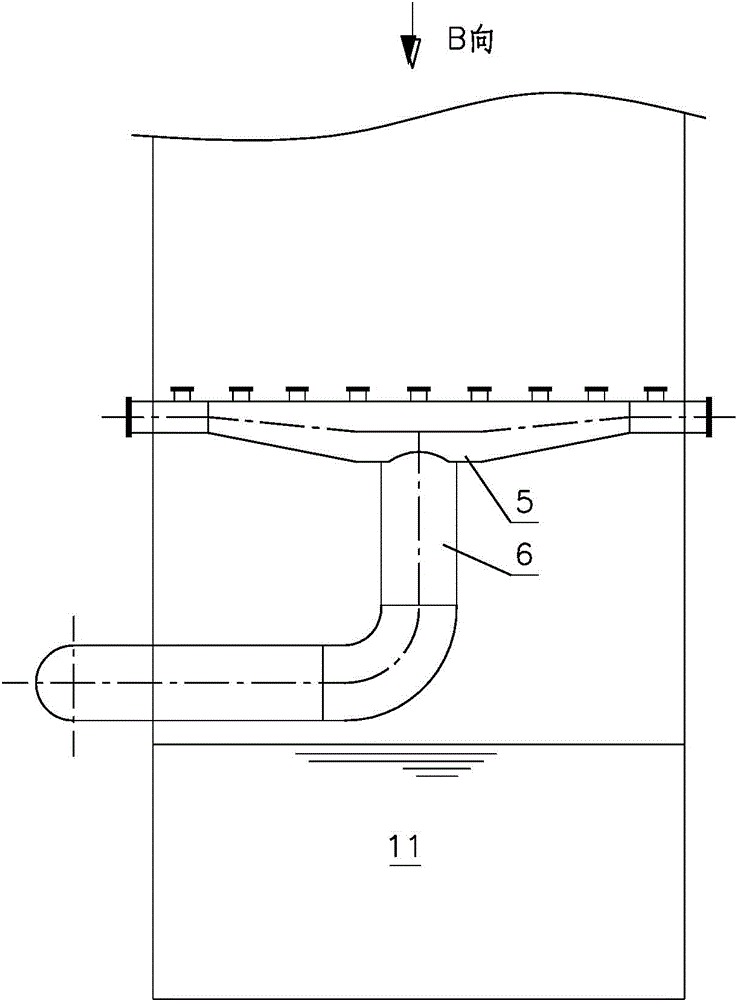

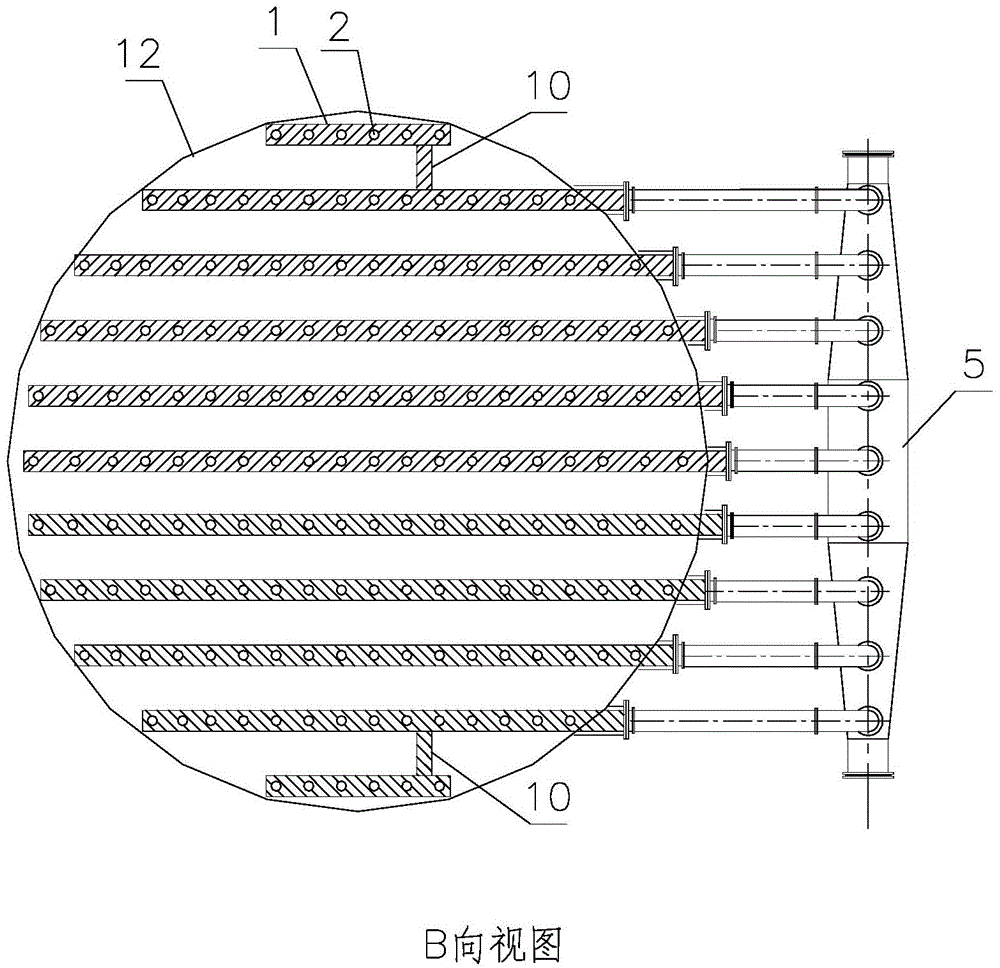

[0053] Such as Figure 1 ~ Figure 3 As shown, the present invention is a double-effect flue gas purification device. The flue gas purification device has a circular steel structure as a whole, and is divided into two areas: the oxidation slurry pool and the absorption reaction area, but the spray pipe and nozzle equipment in the absorption reaction area The structure and arrangement are different from the traditional spray towers with spray pipes and nozzles arranged at high positions. There is an oxidation slurry tank under the absorption tower, and above the oxidation slurry tank is a square inlet flue of the flue gas purification ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com