Water-based tile adhesive and preparation method and construction method thereof

A ceramic tile adhesive and construction method technology, applied in the field of building materials, can solve the problems of insufficient adhesion of cement mortar, unsafe hidden dangers, hollow tiles, etc., and achieve cost saving and construction period, simple preparation method, and excellent waterproof performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

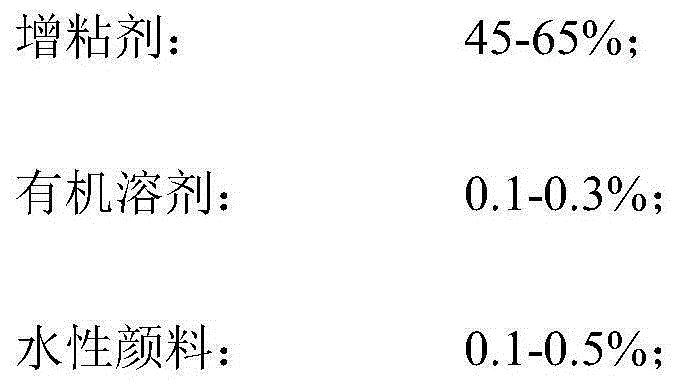

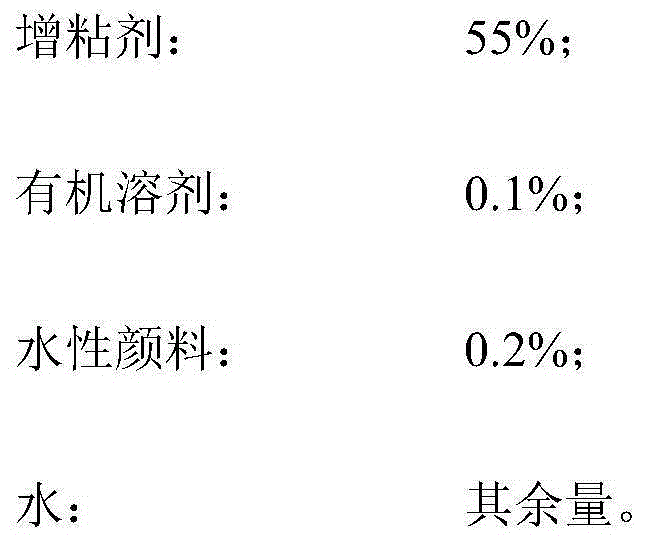

[0022] A water-based ceramic tile adhesive is prepared from the following components by weight percentage: polybutylacrylate: 55%; toluene: 0.1%; water-soluble pigment white: 0.2%; water: the rest.

[0023] According to the composition of the above weight percent, the preparation steps of the adhesive include:

[0024] 1) Stir and mix polybutylacrylate and toluene at 80°C at a speed of 2500rpm to form a mixed component A;

[0025] 2) Stir and mix the water-soluble pigment white and water at room temperature to form a mixed component B;

[0026] 3) Stir and mix the mixing component A in step 1) and the mixing component B in step 2) at 45° C. at a speed of 3000 rpm to obtain the water-based tile adhesive.

[0027] According to tests, the tensile force of the prepared adhesive is 1.5-2.0 kN / 5CM*5CM.

Embodiment 2

[0029] A water-based ceramic tile adhesive is prepared from the following components by weight percentage: polybutyl acrylate: 62%; toluene: 0.3%; water-soluble pigment white: 0.4%; water: the rest.

[0030] According to the composition of the above weight percent, the preparation steps of the adhesive include:

[0031] 1) Stir and mix polybutylacrylate and toluene at 75°C at a speed of 1500rpm to form a mixed component A;

[0032] 2) Stir and mix the water-soluble pigment white and water at room temperature to form a mixed component B;

[0033] 3) Stir and mix the mixing component A in step 1) and the mixing component B in step 2) at 50° C. at a speed of 2000 rpm to obtain the water-based tile adhesive.

[0034] According to tests, the tensile force of the prepared adhesive is 2.5-3.5 kN / 5CM*5CM.

Embodiment 3

[0036] A water-based ceramic tile adhesive is prepared from the following components by weight percentage: ethylene-vinyl acetate copolymer: 45%; toluene: 0.1%; water-soluble pigment yellow: 0.1%; water: the rest.

[0037] Its preparation process is with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com