Height addition construction method for wood-and-steel template

A construction method and formwork technology, which is applied in the field preparation of formwork/formwork/work frame, building components, construction, etc., can solve the problems of unfavorable powder coating exterior decoration, prone to misalignment, and not one, so as to save manpower , Convenience in construction and improvement of project quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

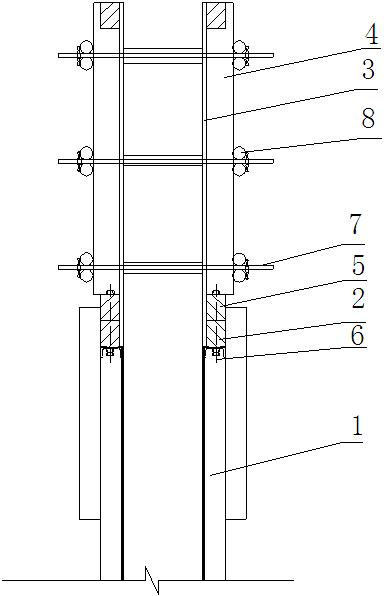

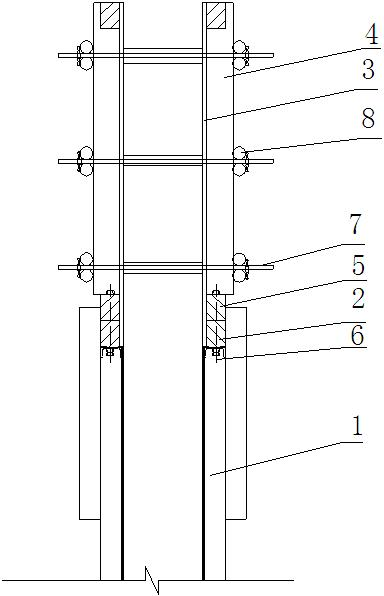

[0007] like figure 1 As shown, a small wooden square 2 is arranged on the upper end of the lower large formwork 1, a vertical large wooden square 4 is arranged on the back of the upper formwork 3, and another small wooden square 5 is arranged at the lower end of the large wooden square 4, and the two small wooden squares are connected by bolts 6. Squares 2 and 5 are fixedly connected to each other, and the inner surface of the lower formwork 1 and the inner surface of the upper formwork 3 are on the same plane, and the large wooden square 4 is fixed by the pull bolts 7 and the transverse back corrugated 8, and then poured.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com