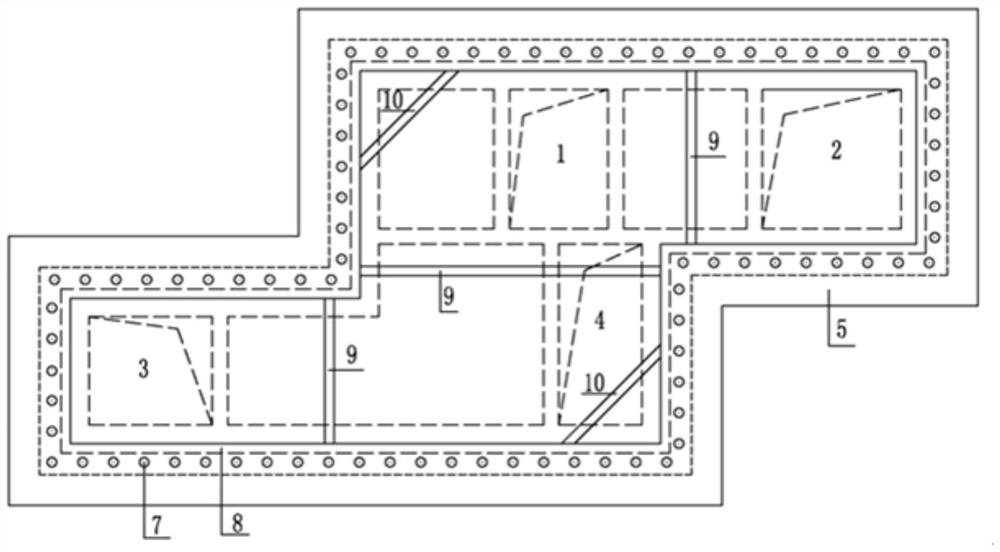

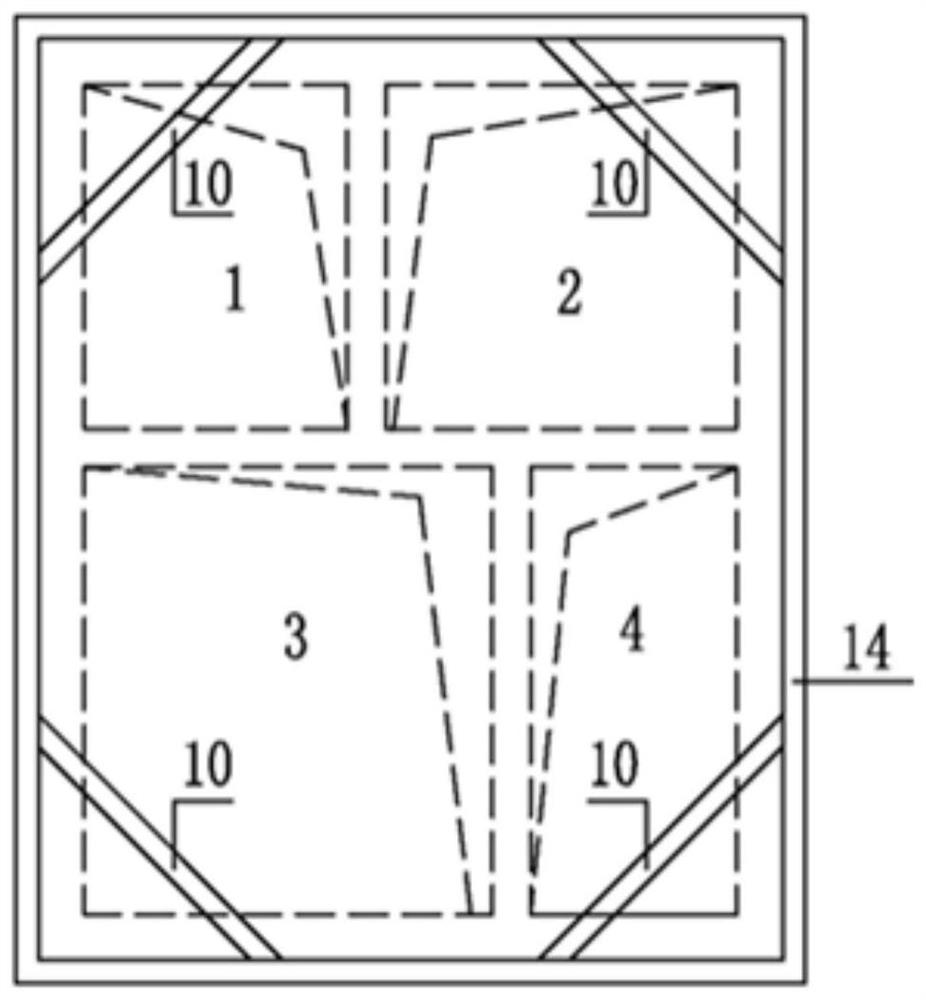

Special-shaped upside-down well wall construction method for simultaneously building vertical shaft and throwing-out air shaft

An upside-down well wall and construction method technology, which is applied in shaft equipment, sinking, earthwork drilling and mining, etc., can solve the problems of secondary inversion of the site, reduced construction efficiency, and extended civil construction period, so as to achieve convenient organization and save engineering materials , The effect of high mechanical work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

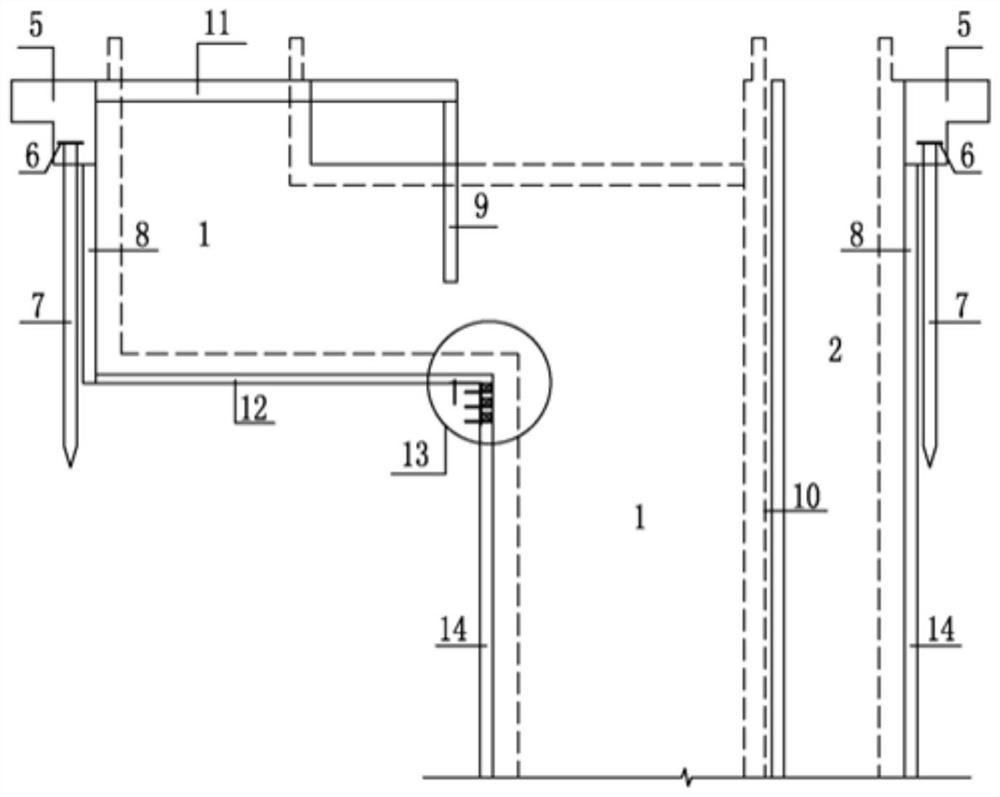

[0034] In order to enable those skilled in the art to better understand the technical solution of the present invention, the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0035] This embodiment provides a construction method for a special-shaped upside-down shaft wall in which the vertical shaft and the blow-out air shaft are built at the same time, and the method includes the following steps:

[0036] Step S1, three links and one leveling of the site, fence construction.

[0037] Step S2, setting the steel pipe pile 7, the bottom of the pile enters under the foundation pit of the blow-out wind shaft, and also serves as a temporary soil retaining member before the initial support 8 of the blow-out wind shaft is constructed.

[0038] Step S3, excavating a shallow foundation pit at the mouth, and molding the locking ring 5 structure.

[0039] Step S4, excavate the rock-soil body downwards by hanging...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com