Girder embracing type tower crane foundation steel bearing table and construction method thereof

A technology of tower crane foundation and construction method, which is applied in basic structure engineering, construction and other directions, can solve the problems of cumbersome construction and demolition process steps, affecting construction cost during construction period, wasting materials and human resources, etc. Simple and convenient disassembly and stable support

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

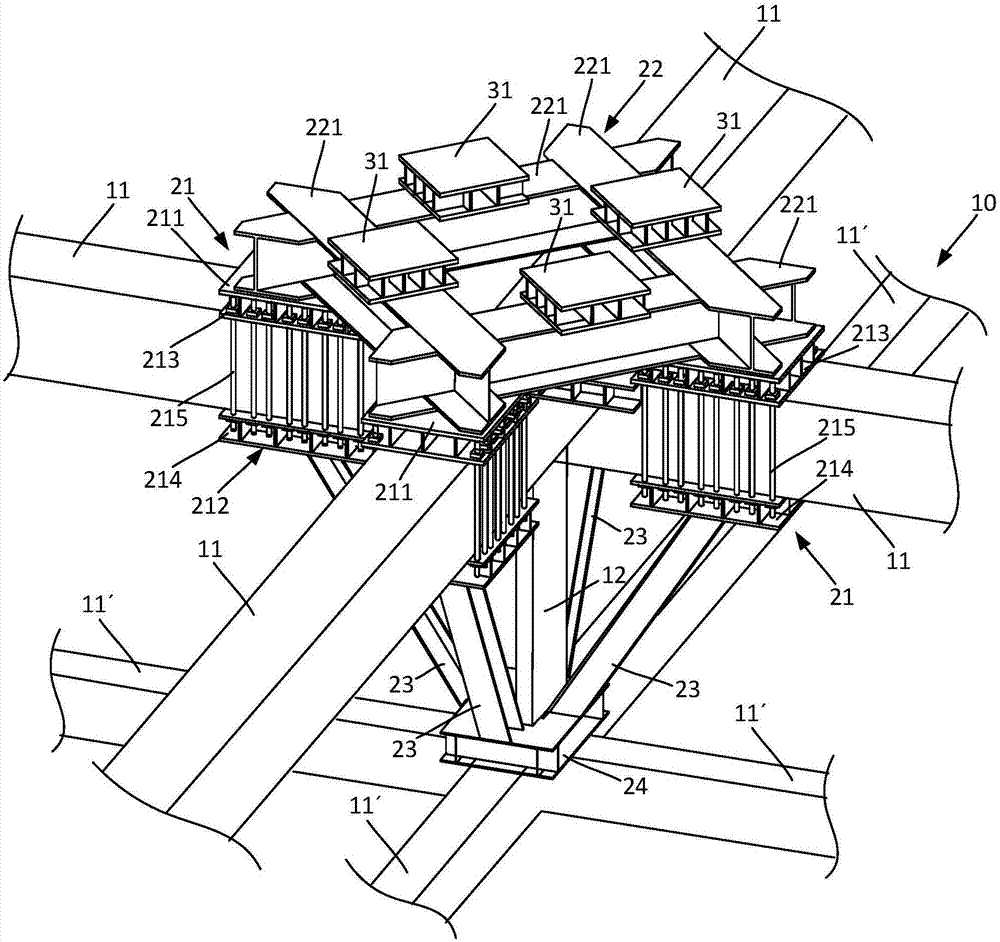

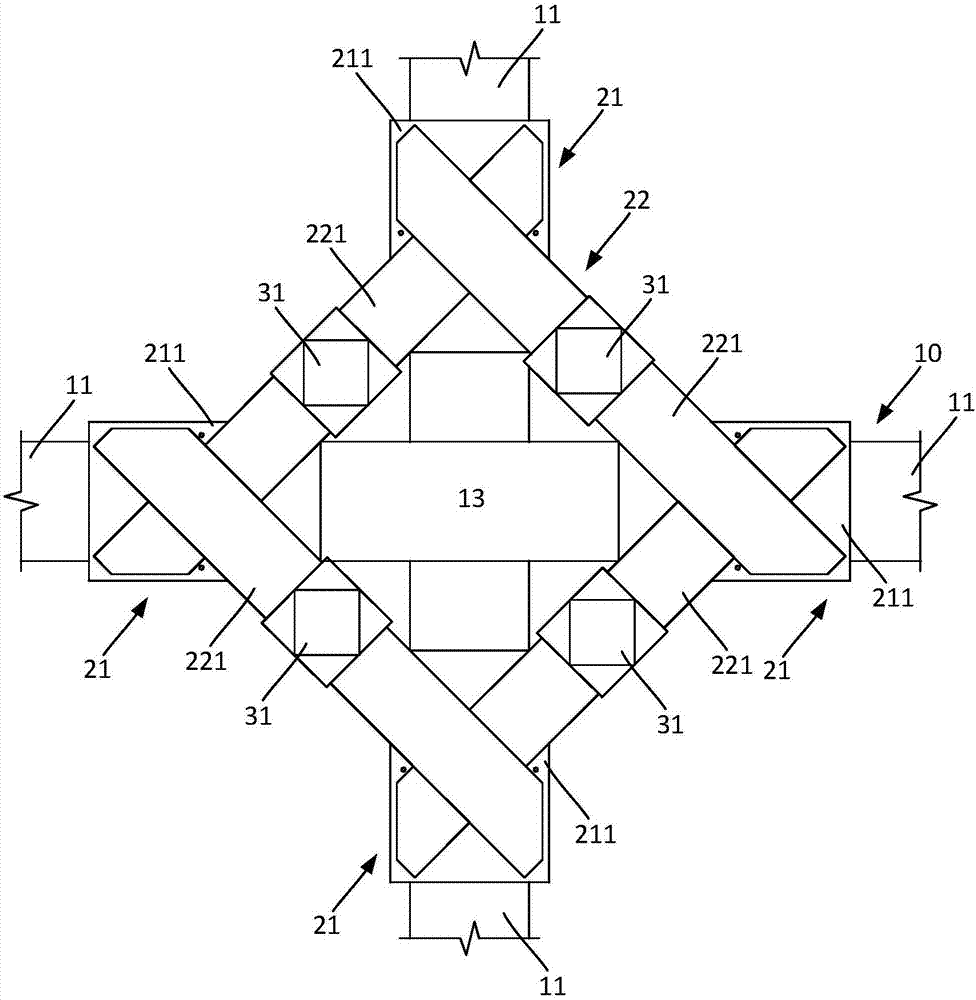

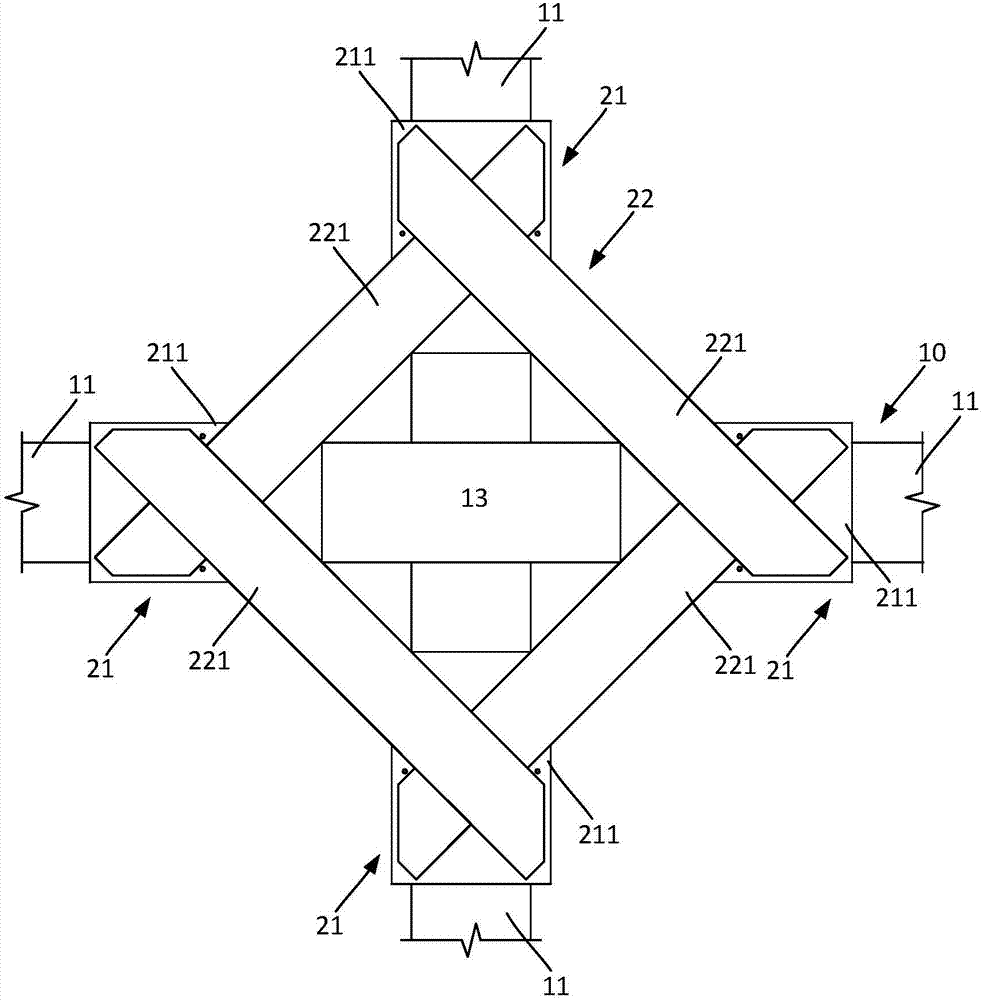

[0043] refer to figure 1 , the present invention provides a beam-holding type tower crane foundation steel cap and its construction method, using the nodes of the frame beams and frame columns of the existing structure (existing building structure) as the supporting foundation for tower crane installation, and adopting a beam-holding The structure is hugged with the frame beam to form a more stable overall force-bearing system, and then the basic steel cap is installed on the beam-holding structure, and the tower crane is installed through the basic steel cap. The invention adopts the mechanical installation method and the effective force transmission system between the existing beam-column nodes, avoiding the traditional use of the existing beam-column nodes as the vertical load-bearing structure of the foundation cap of the tower crane. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com