Building thermal insulation wall

A technology for building thermal insulation and thermal insulation body, which is applied to buildings, building components, building materials, etc., can solve the problems of ineffective thermal insulation, inability to effectively block heat transfer, discontinuous thermal insulation materials, etc., to save the construction period, Eliminate fire hazards and have good fire protection effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention is not limited by the following examples, and specific implementation methods can be determined according to the technical solutions of the present invention and actual conditions.

[0015] Below in conjunction with embodiment and accompanying drawing, the present invention will be further described:

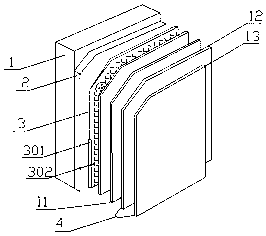

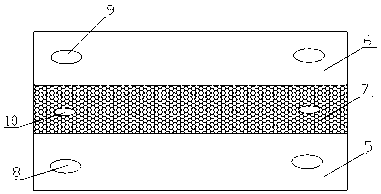

[0016] Such as figure 1 , 2 As shown, the thermal insulation wall of the building includes a foundation wall 1, a mortar leveling layer 2, an anti-crack protection layer 3 and a finish layer 4, and the foundation wall 1 is built by a plurality of composite thermal insulation bricks using a wall adhesive into; each composite heat insulating brick includes a first brick body 5, a second brick body 6 and an insulating body 7; the first brick body 5 and the second brick body 6 are rectangular parallelepiped bricks of the same size; the insulating body 7 It is a rectangular parallelepiped insulation board sandwiched between the first brick body 5 and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com