Mounting structure of outer wall rock wool heat preservation integrated plate of high-rise housing and construction method

A technology for high-rise residences and installation structures, which is applied in building thermal insulation materials, building components, building structures, etc., can solve the problems of falling integrated boards and heavy installation weight, and achieve the effect of avoiding overall falling off and avoiding safety and quality accidents.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

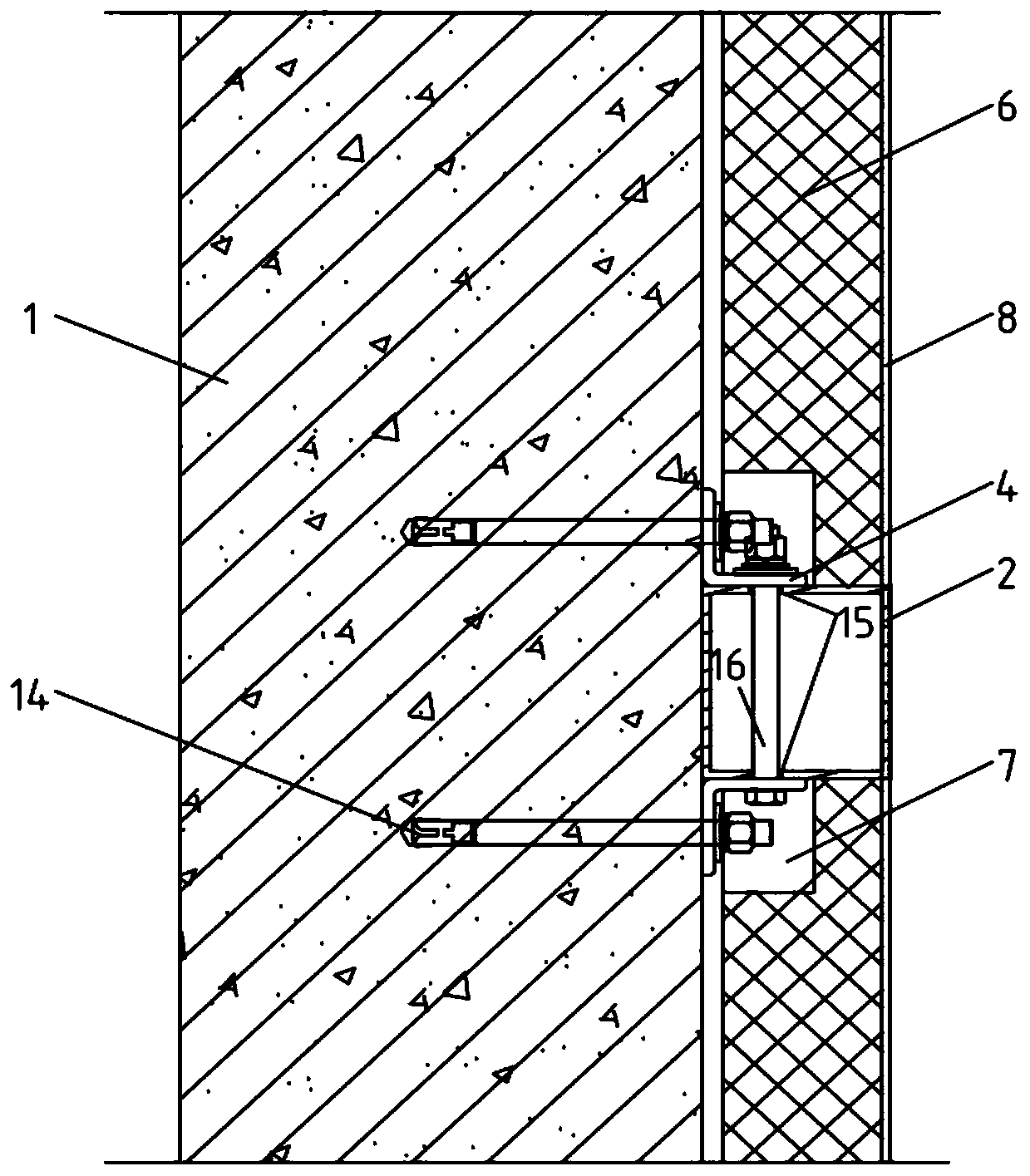

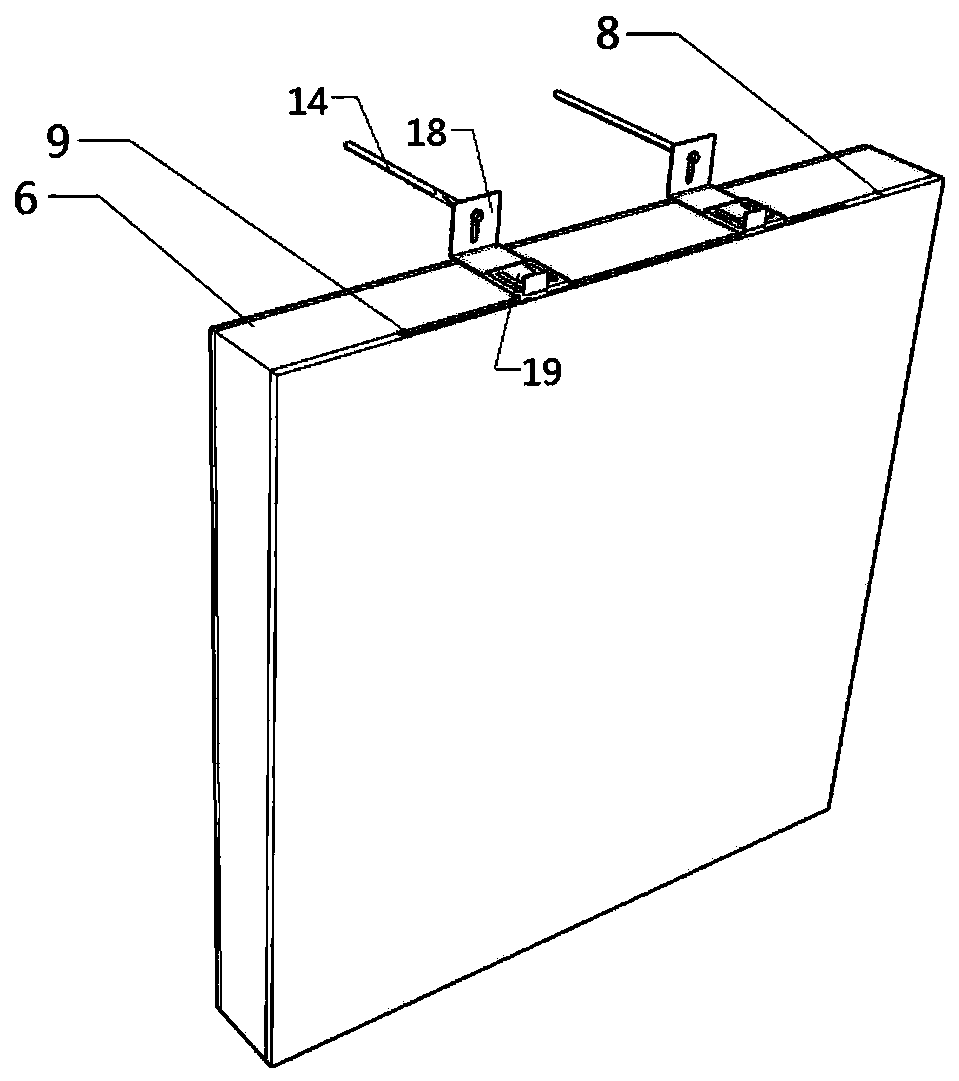

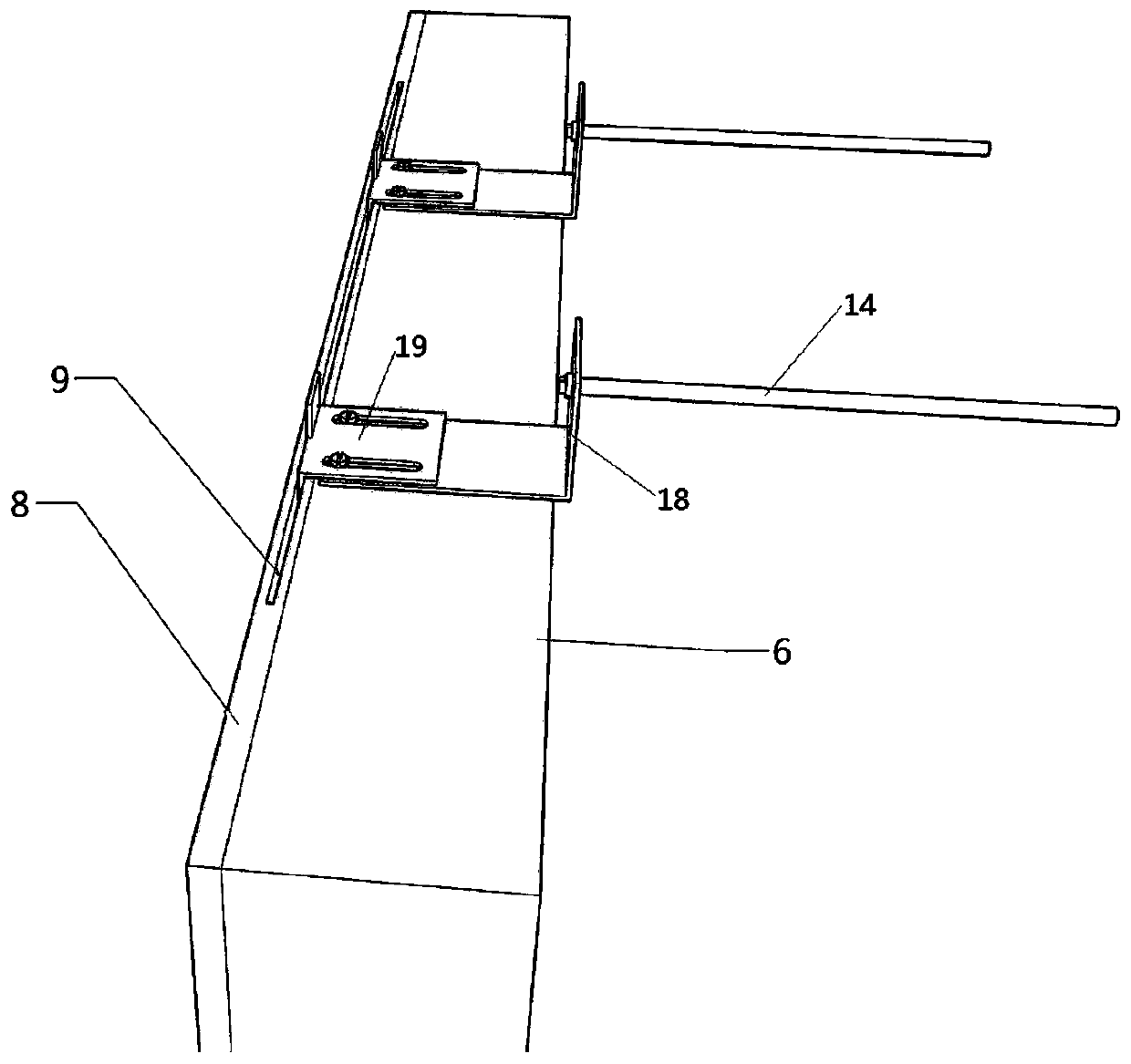

[0053] See attached Figure 1-8 It is a schematic diagram of the overall and partial structure of an embodiment of the present invention. The present invention provides a construction method for an aluminum alloy grille on the exterior wall of a high-rise residential building and a rock wool and rock wool thermal insulation integrated board. The installation structure is as follows:

[0054] Aluminum alloy grille, the aluminum alloy grille is composed of a plurality of aluminum alloy square tubes 2 horizontally fixed on the installation wall 1 and parallel to each other; the integrated rock wool insulation board 20, the integrated rock wool insulation board 20 is located on the aluminum alloy square tube 2 The lower end of the rock wool insulation integrated board 20 between the two aluminum alloy square tubes 2 adjacently arranged up and down is abutted against the aluminum alloy square tube 2 below.

[0055] The specific construction process is as follows:

[0056] ①Hanging...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com