Steel pipe pile cofferdam structure of reservoir area in front of dam and construction method thereof

A technology for steel pipe piles and reservoir areas, which is applied in basic structure engineering, sheet pile walls, embankments, etc., can solve the problems of difficult construction period control, high construction cost, low underwater construction efficiency, etc., and achieves good water-stop effect and structural strength. High and good overall effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

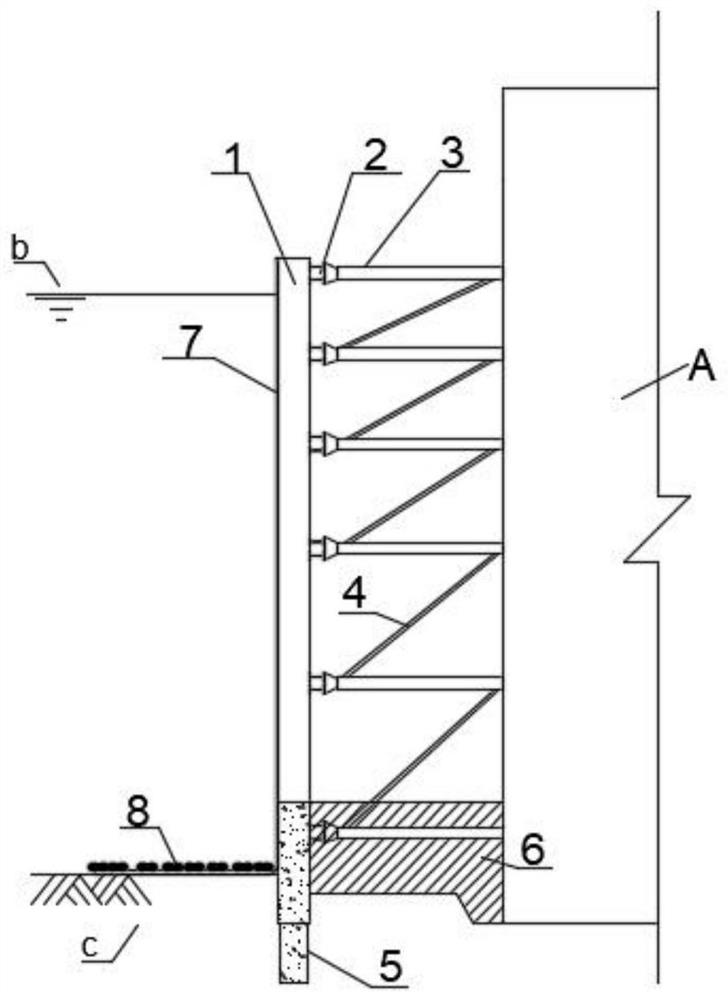

[0054] A construction method for a steel pipe pile cofferdam structure in a reservoir area in front of a dam, comprising the following steps:

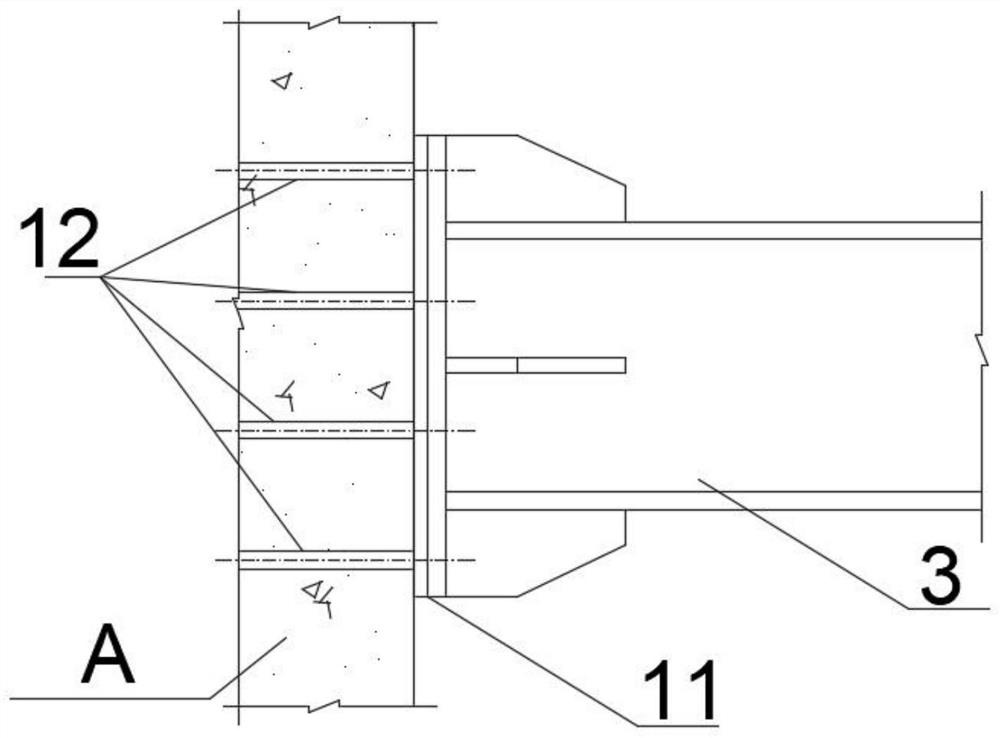

[0055] Step 1: Use the static pressure method or the vibration excitation method to insert the locking steel pipe pile 1 to the foundation bedrock surface on the water work platform;

[0056] Step 2: After the locking steel pipe pile 1 is sunk in place, use a rotary drilling rig with a roller bit to drill the pebble gravel layer and bedrock rock layer at the bottom of the pile from the locking steel pipe pile 1, and then lower the hole after clearing the hole. Reinforcement cage, and finally pour underwater concrete to complete the rock-socketed concrete pile 5; after the concrete age of the rock-socketed concrete pile 5 reaches 7 to 10 days, the locking steel pipe pile 1 is filled with sand or gravel to improve the strength of the steel pipe pile. Stability under force to prevent local buckling deformation of locking steel pipe pile 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com