Underground diaphragm wall with pit face having water level lowering function

A technology for underground diaphragm walls and pit faces, which is applied to sheet pile walls, excavation, construction, etc., can solve the problems of occupying construction sites and high overall costs, and achieve the effect of saving construction period and cost and having strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] See attached picture:

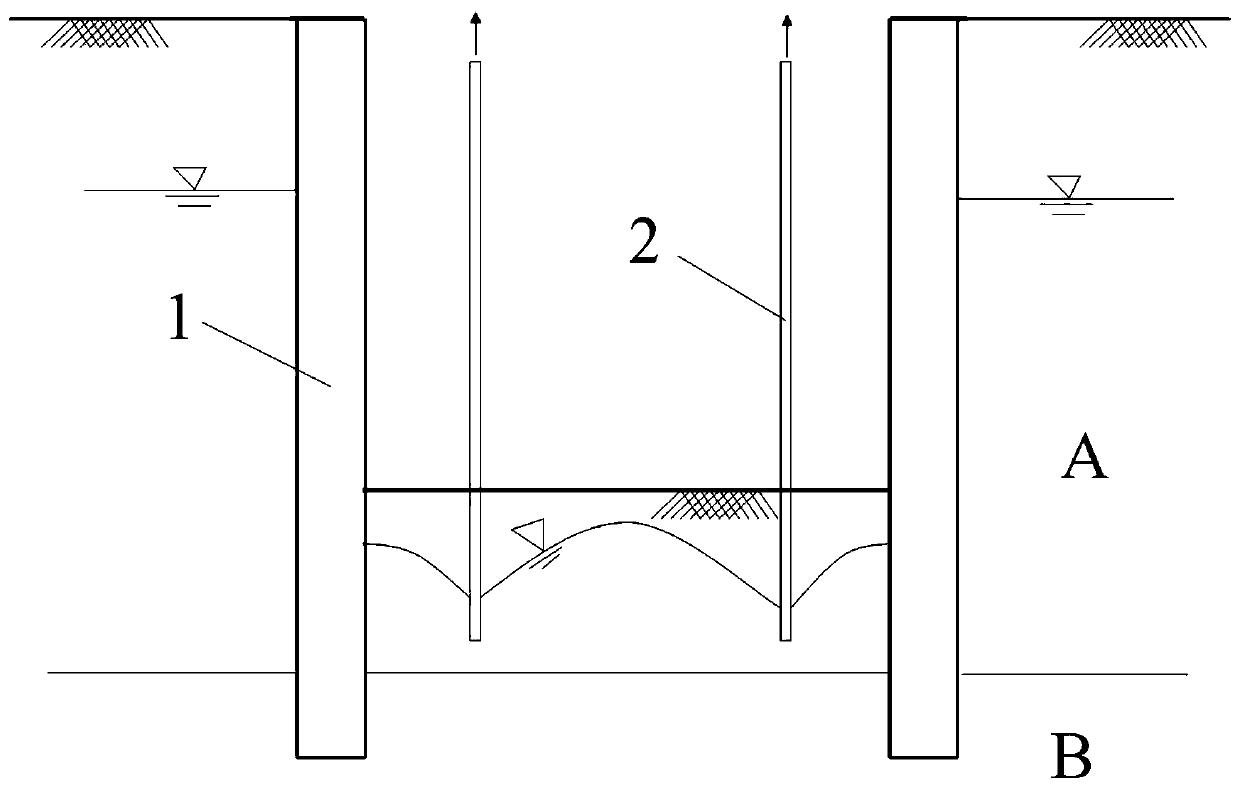

[0029] The traditional underground diaphragm wall 1 is embedded in the water-resisting layer B. The traditional underground diaphragm wall 1 blocks the penetration of groundwater outside the foundation pit to the interior of the foundation pit. It only needs to pump water inside the foundation pit to lower the water level. Digging has no effect. At present, the general practice is to install traditional dewatering wells 2 inside the foundation pit to lower the groundwater level in the pit, such as figure 1 shown.

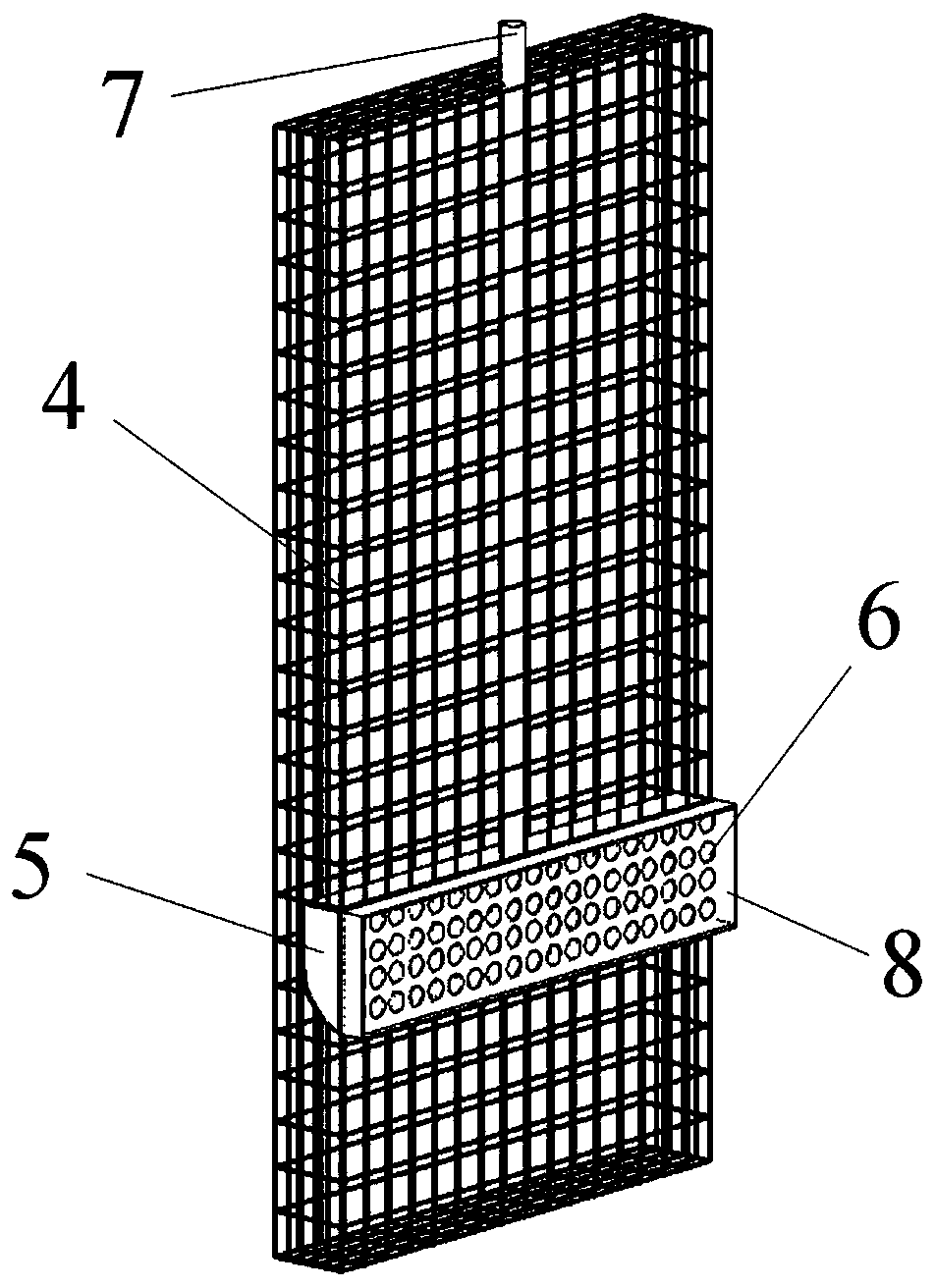

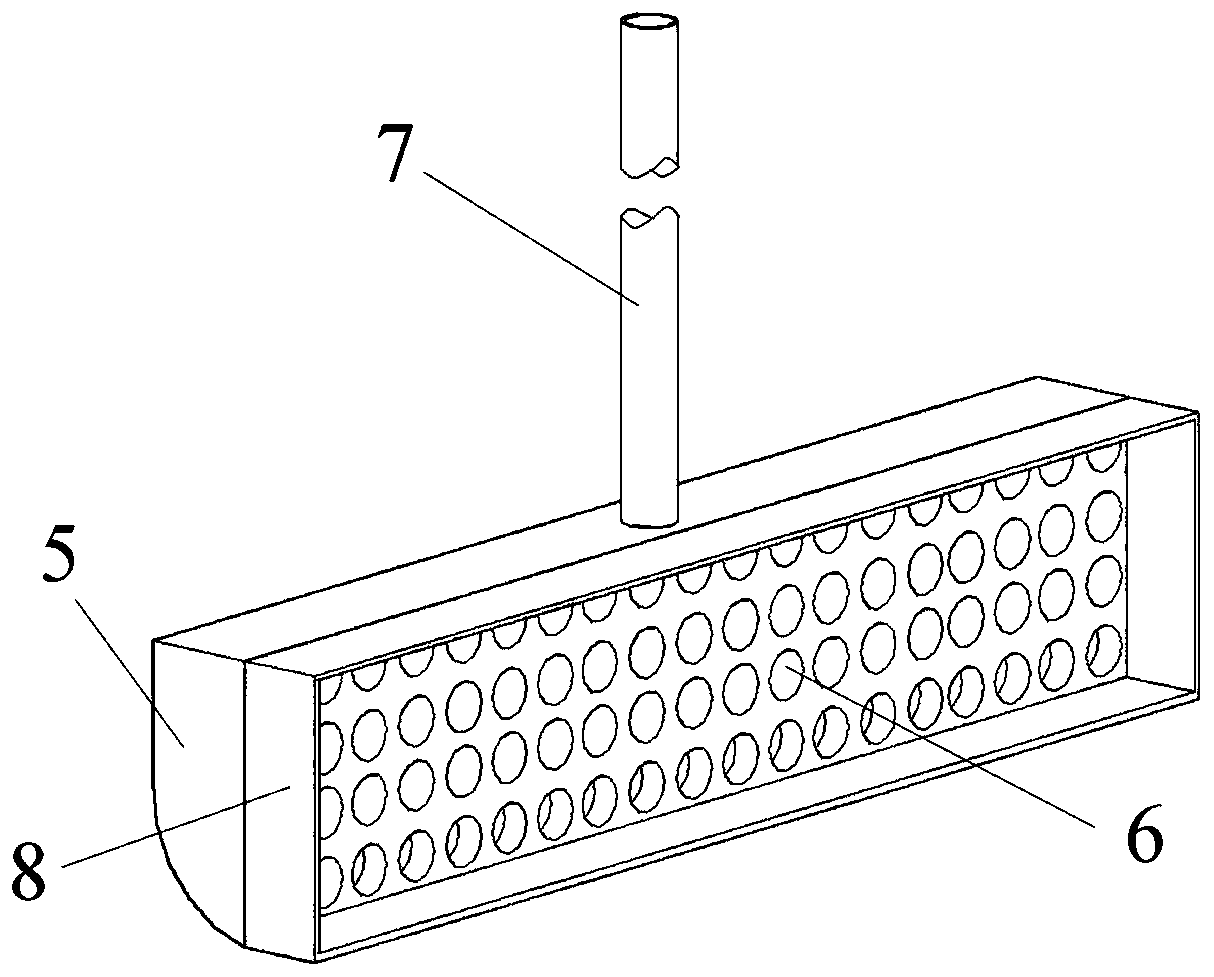

[0030] An underground continuous wall with a function of precipitation on the face of the pit, comprising a steel cage 4, a round pipe 7 and a water storage tank 5, the round pipe 7 is vertically arranged and buried in the inside of the steel cage 4, the top of the round pipe 7 is The top of the steel cage 4 protrudes, and the water storage tank 5 is fixed on the lower part of the pit face of the steel cage 4. The water storage tank ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com