Supporting part of reinforcement cage and application method thereof

A technology for supporting parts and reinforcing cages, which is applied in construction, infrastructure engineering, sheet pile walls, etc., can solve the problems of non-reusable cross braces, loose cross braces, and deformation of reinforcing cages, saving engineering materials and The construction period, the effect of improving the overall strength and reducing the difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

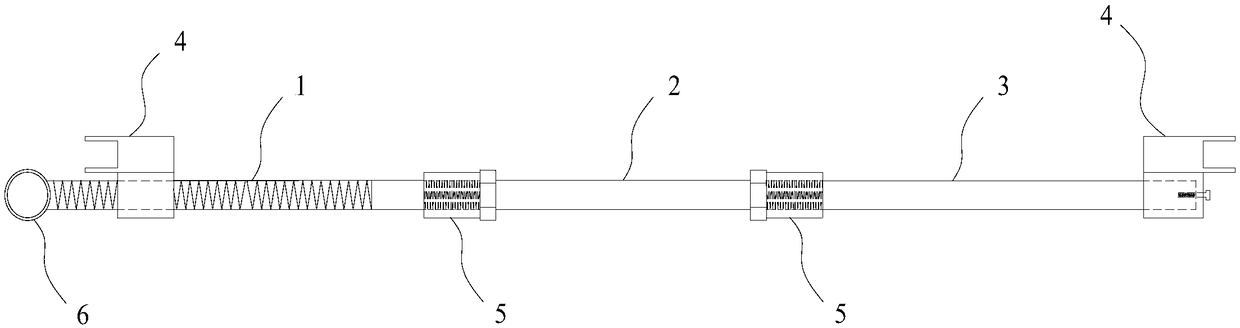

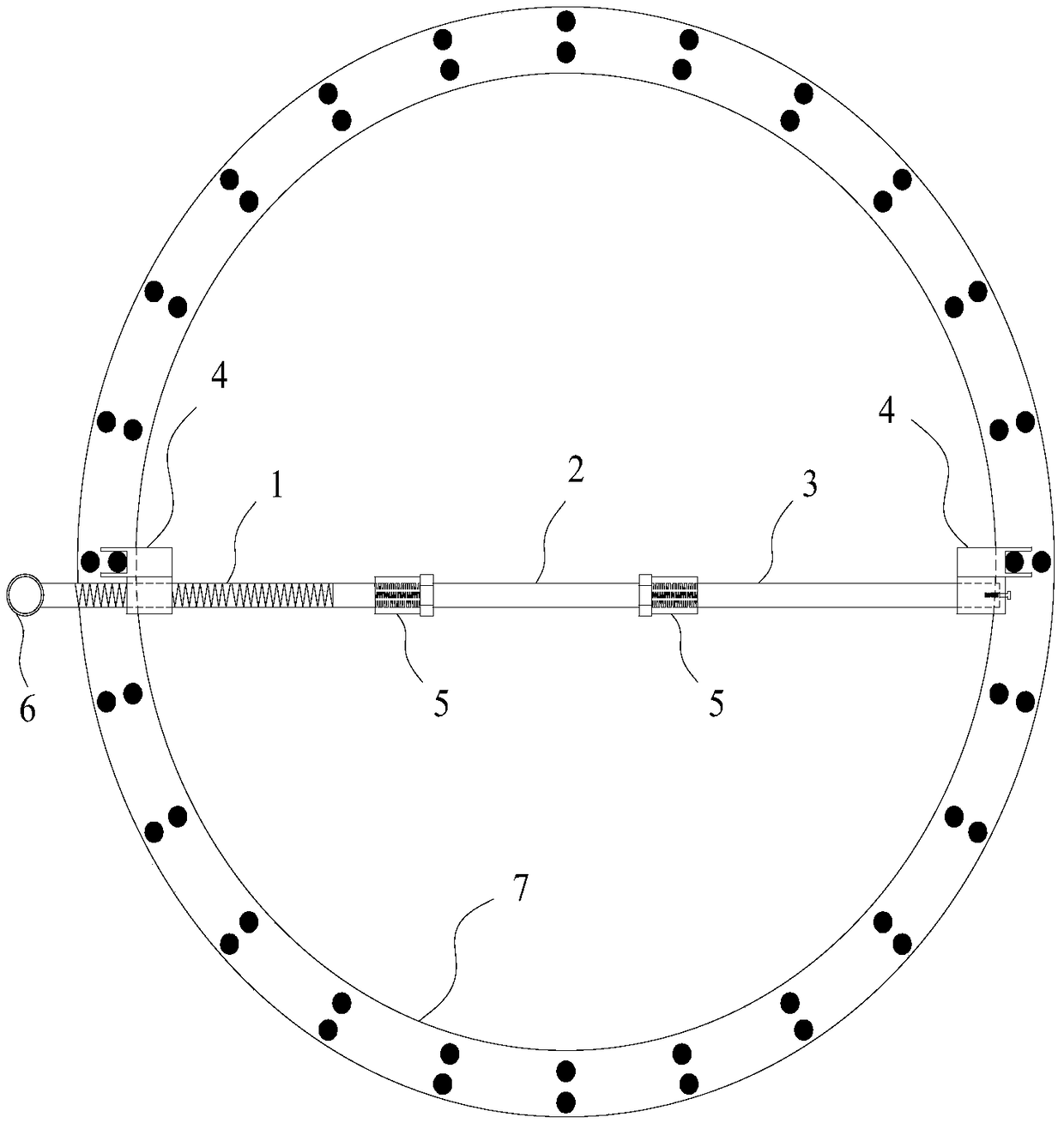

[0037] A support part of a reinforcement cage according to the present invention, such as Figure 1-2 As shown, it includes a rod one 1, a connecting part 2 and a rod two 3, and the connecting part 2 includes a straight rod, and the rod one 1 and the rod two 3 are respectively connected to the two ends of the straight rod, Preferably, the first rod 1 and the second rod 3 are detachably connected to both ends of the in-line rod, and further preferably, the rod one 1 and the second rod 3 are respectively screwed to the in-line rod The two ends of the piece, preferably, the rod one 1 is a screw rod, the slot 4 on the rod one 1 is threadedly connected to the screw rod, the end of the screw rod is connected with a torque cylinder 6, and the rod two 3 The said draw-in slot 4 is fixedly connected to the end of said rod 3, and said rod one 1 and rod two 3 are all provided with fastening nuts 5 at the joints of said rod one and rod two 3, and said rod one 1 Collinear with bar two 3, e...

Embodiment 2

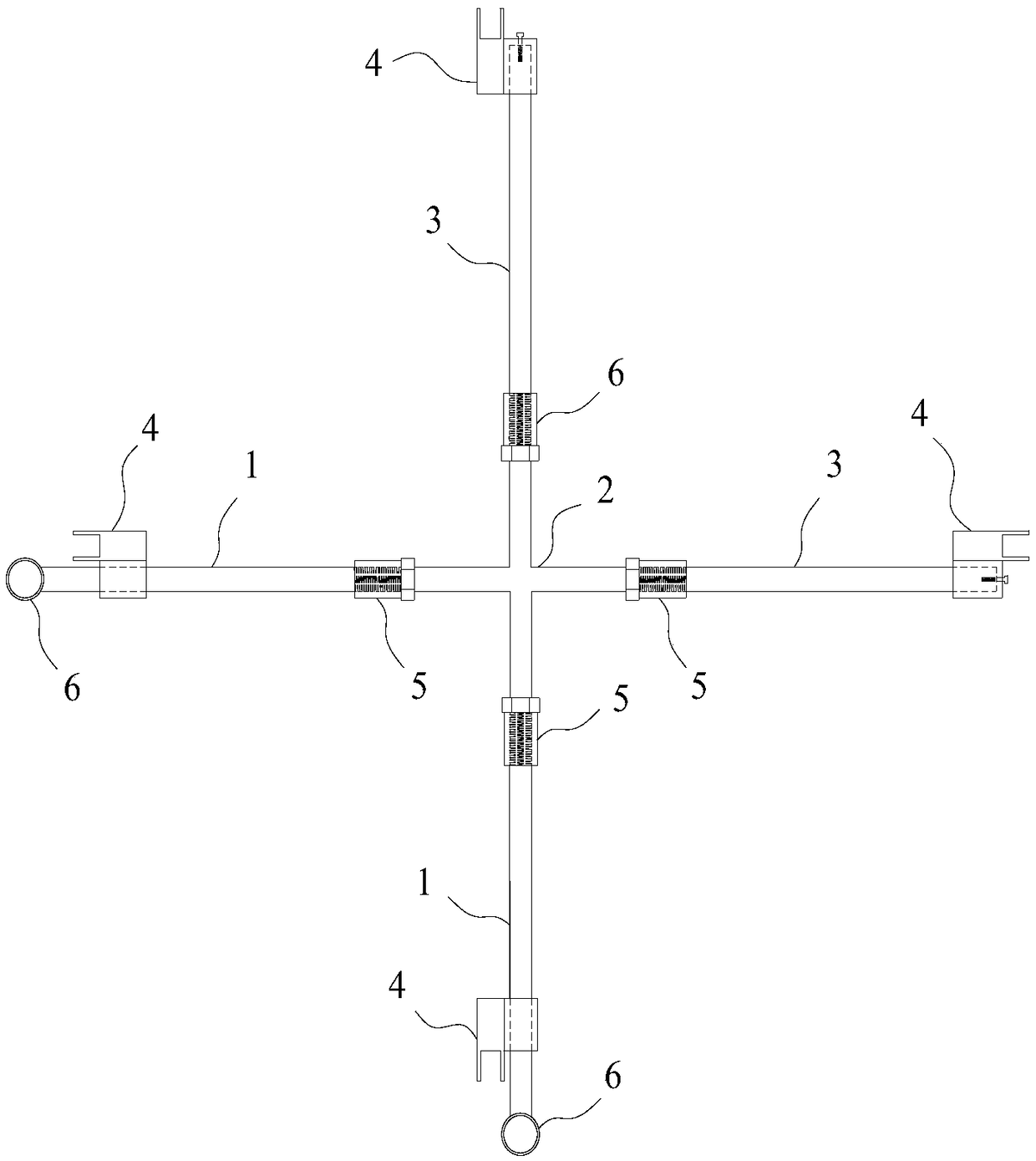

[0040] A support part of a reinforcement cage according to the present invention, such as image 3 As shown, its structure is roughly the same as that of Embodiment 1, the difference is that the connecting part 2 includes two in-line rods, and each of the two ends of the in-line rods is respectively connected to one of the rods One 1 and one rod two 3, the two said in-line rods are integrally formed structural parts perpendicular to each other, the two rods one 1 are all polished rods, and the clips arranged on the rod one 1 The slot 4 is slidingly connected to the rod one 1 through a sleeve, and the sleeve is provided with a locking bolt.

[0041] During use, earlier the draw-in groove 4 on the described bar two 3 of two described inline rods blocks the inboard of reinforcement cage 7, slides the draw-in groove 4 on two bar one 1 respectively then and blocks corresponding described The inner side of the reinforcement cage 7 opposite to the rod 2 3 can be fastened without loo...

Embodiment 3

[0043] The using method of the support member of a kind of reinforcement cage of the present invention adopts the support member of any one reinforcement cage as in embodiment 1-2, and its use method comprises the following steps:

[0044] a. First use a card slot 4 on the straight rod to block the inner side of the reinforcement cage 7;

[0045] b. Adjust the distance between the two slots 4 on the same straight bar, so that the other slot 4 clamps the inner side of the other side of the reinforcement cage 7;

[0046] c. Connect the supporting part with the reinforcement cage 7 with a rope to complete the installation of the supporting part.

[0047]Using this method, according to the diameter of the steel cage 7 to be supported, select the connecting part 2 of suitable length, then clamp the slot 4 of the rod 23 on the inside of the steel cage 7, and then rotate the torque cylinder 6 or slide the slot 4 to make The draw-in groove 4 on the bar one 1 blocks the other side of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com