Dry-dock-free underwater shallow-buried open-cut large channel basic structure unit and construction method

A technology of basic structure and structural unit, which is applied in the field of basic structural unit and its rapid construction of large-scale passages of shallow buried open-cut underwater without dry dock, can solve the problems of high cost of temporary projects, long construction period, and easy torsion phenomenon, etc., to achieve Save the overall project cost and construction period, reduce the required manpower, the effects of efficient floating and accurate sinking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

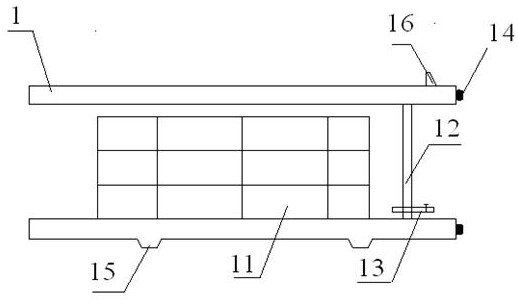

[0035] Example 1: as figure 2 As shown in the figure, a basic structural unit of a large-scale channel of shallow buried and open-cut underwater without dry dock, the basic structural unit 1 is formed by integral casting of the top plate, the bottom plate and the side walls on both sides, one end of the basic structural unit is provided with a sealing door 12, and the other end is It is an open structure, the lower end of the sealing door 12 is provided with a drainage and pressure relief valve 13, the end of the basic structural unit on the side of the sealing door 12 is surrounded by a rubber water stop belt 14, and the interior of the basic structural unit 1 is provided with an adjustable inlet. 2. The floating and pressure cabin 11 with displacement capacity, the bottom of the basic structural unit 1 is provided with at least four axis positioning feet 15, the top plate of the basic structural unit 1 is provided with an axial zipper 17 or is matched with the axial zipper 1...

Embodiment 2

[0040] Example 2: as Figures 1 to 4 As shown in the figure, a method for rapidly constructing a large-scale channel without dry-dock underwater by applying the basic structural unit described in Embodiment 1 specifically includes the following steps:

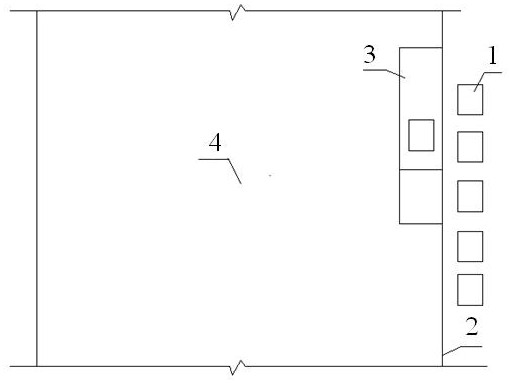

[0041] S1, such as figure 1 As shown, the basic structural units 1 described in the first to Nth Embodiments 1 are directly prefabricated on the flat ground near the bank line 2 of the channel water area 4; wherein, the schematic structural diagram of the basic structural unit 1 is as follows figure 2 shown;

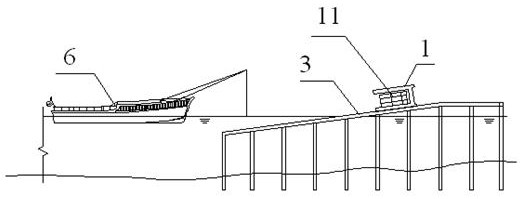

[0042] S2, such as Figure 4 As shown, the cast-in-place structural unit 7 for docking with the first basic structural unit prefabricated in step S1 is constructed by the cofferdam open-cut method under the bank line 2 of the channel water area 4, and the cast-in-place structural unit 7 is connected A sealing door 12 is provided at the end, and a drainage and pressure relief valve 13 is arranged at the lower end of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com