Method for external insulation construction of polystyrene board thin plastered surface in cold and windy area

A polystyrene board and construction method technology, applied in thermal insulation, building components and other directions, can solve the problems of large temperature difference between winter and summer, great difference between cold and summer, poor thermal insulation and wind resistance of EPS board exterior wall, etc., to achieve good integrity and improve thermal insulation performance. , The effect is firm and stable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

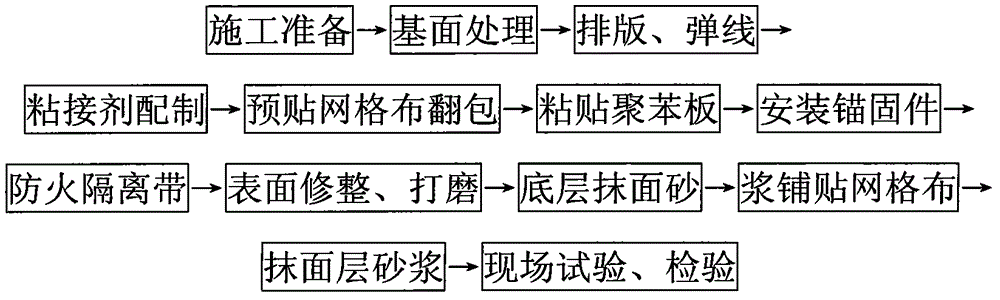

[0026] Embodiment 1: as attached figure 1 As shown, the construction method flow is: construction preparation, base surface treatment, typesetting, elastic line, fire isolation belt, surface trimming, polishing, bottom plastering sand, slurry laying grid cloth, plastering mortar and field test and inspection.

[0027] The specific construction methods include:

[0028] ①Construction preparation;

[0029] Conscientiously familiarize yourself with construction drawings, atlases and specification requirements; prepare construction plans and measures for key parts and go through the approval procedures, and assign special personnel to be responsible for the collection and arrangement of technical data; organize workers to conduct pre-job training, and master the construction technology of external wall insulation proficiently. Only after obtaining the "Employee Training Qualification Certificate" can they work on the job; according to the construction drawings, do a good job in the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com