Composite insulation building blocks and production method thereof

A composite thermal insulation and block technology, which is applied in the field of masonry wall materials, can solve the problems of warping of organic thermal insulation boards, poor control of purchase channels, and control of project quality, so as to achieve simple construction and save construction period and construction cost. , The effect of improving the molding speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

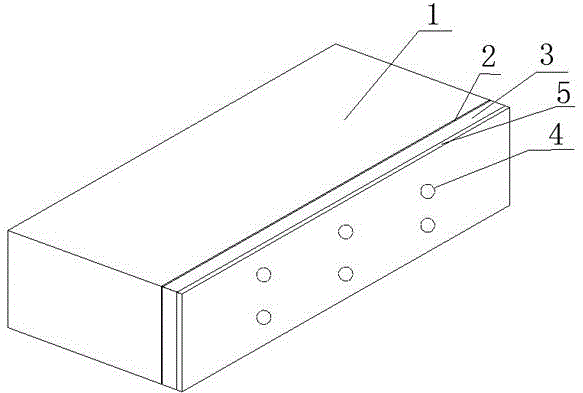

[0024] A composite thermal insulation block, which is composed of an autoclaved aerated concrete block (1), an adhesive layer (2), a thermal insulation board (3), an anchor bolt (4), and an adhesive protective layer (5), wherein the autoclaved The aerated concrete block, adhesive layer, and insulation board are connected in sequence through anchor bolts, and the adhesive protection layer is covered on the outside; the adhesive layer and the adhesive protection layer are gypsum-based inorganic insulation mortar, and the insulation board is made of extruded board.

[0025] The gypsum-based inorganic thermal insulation mortar is made by adding water and stirring components such as building gypsum, alkaline activator, aggregate, admixture, and vitrified microspheres. 25% activator, 0.1% water reducer, 0.6% water retaining agent, 0.25% water repellent, 10% vitrified microbeads, 0.35% styrene-acrylic emulsion, 0.23% fiber, 0.7% polyvinyl alcohol, 18% sand, slow Coagulant 0.08%; wate...

Embodiment example 2

[0036] A composite thermal insulation block, which is composed of an autoclaved aerated concrete block (1), an adhesive layer (2), a thermal insulation board (3), an anchor bolt (4), and an adhesive protective layer (5), wherein the autoclaved The aerated concrete block, adhesive layer, and insulation board are connected in sequence through anchor bolts, and the adhesive protection layer is covered on the outside; the adhesive layer and the adhesive protection layer are gypsum-based inorganic insulation mortar, and the insulation board is polyurethane board.

[0037] The gypsum-based inorganic thermal insulation mortar is made by adding water and stirring components such as building gypsum, alkaline activator, aggregate, admixture, vitrified microbeads, and the components are formulated according to the following weight ratio: building gypsum 46%, alkali Sex stimulating agent 23%, water reducing agent 0.05%, water retaining agent 0.6%, water repellent agent 0.3%, vitrified micr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com