Rapid fixture special for eccentric adjustment of rotary encoder circular grating

A rotary encoder and eccentric adjustment technology, which is applied in the direction of manufacturing tools and workpiece clamping devices, can solve problems such as low efficiency and complicated clamping operations, and achieve the effects of improving positioning accuracy, simple structure, and convenient manual operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The following non-limiting examples can enable those skilled in the art to understand the present invention more fully, but do not limit the present invention in any way.

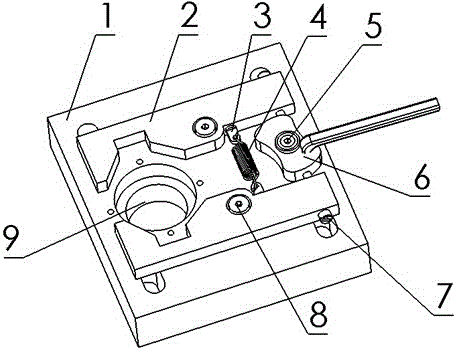

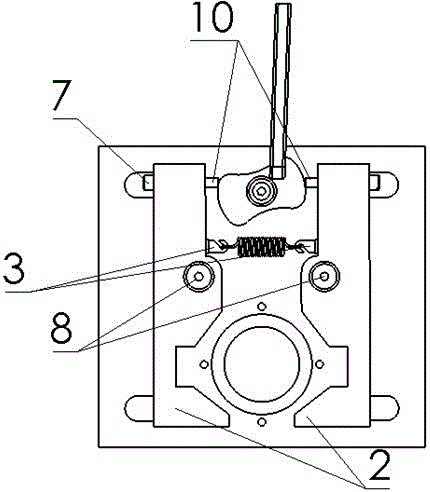

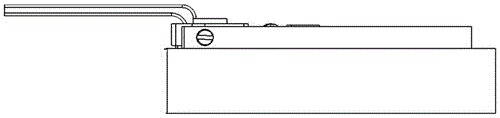

[0016] see Figure 1-5 , the present invention provides a technical solution: a special quick-change fixture for adjusting the eccentricity of a rotary encoder circular grating, including a fixed plate 1, a splint 2, a hook screw 3, a tension spring 4, a bolt type roller needle bearing 5, a dial Rod cam 6, external thread pin 7, bolt type roller needle roller bearing 8, stepped pin 10, cylindrical compression spring 13; fixed plate 1 is a square block structure, equipped with encoder positioning seat 9, bolt type roller needle roller bearing 5 The bolt type roller needle roller bearing 8 is installed on the fixed plate 1, and the lever cam 6 is installed on the bolt type roller needle roller bearing 8 through a transition fit to realize the rotary motion; the splint 2 is provided with a positioning h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com