Zipper cutting-off mechanism

A technology of cutting mechanism and zipper, applied in clothing, textiles, papermaking, fasteners and other directions, can solve the problems of breaking, cutting knife wear, not considering the stroke range of the cutting knife, etc., to improve impact resistance, worktable clean and tidy, The effect of ensuring safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

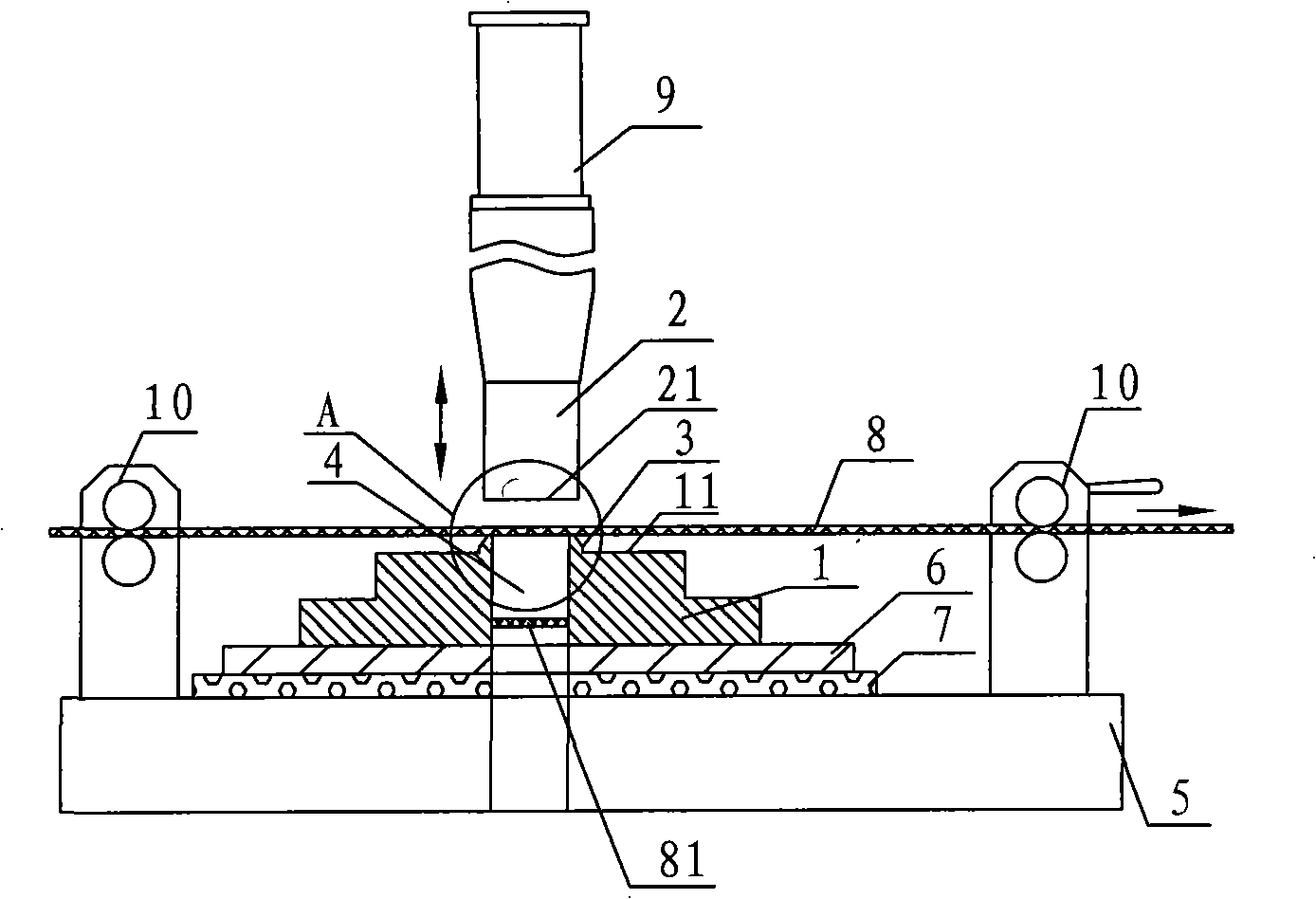

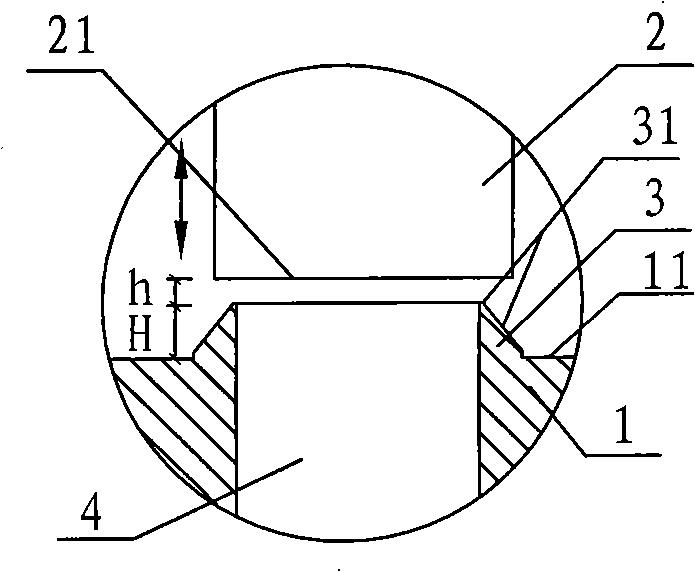

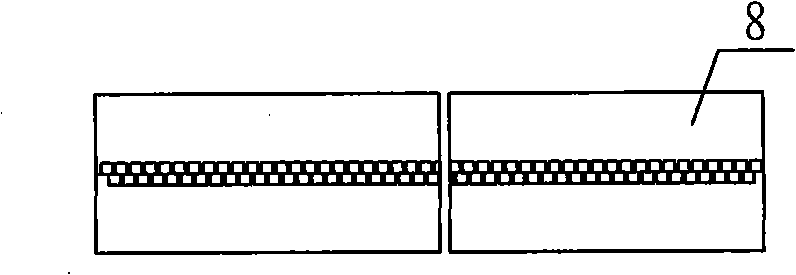

[0036] Such as figure 1 , 2As shown, the zipper cutting mechanism includes a mold 1 and an ultrasonic head 2 fixedly arranged. The ultrasonic head 2 is on the same axis as the mold 1, and the ultrasonic head 2 is driven by the driving mechanism 9 to reciprocate the ultrasonic head 2, and the ultrasonic head 2 is electrically connected to the ultrasonic generator (not shown); The working surface 11 of the mold 1 corresponding to the working end surface 21 of 2 is provided with a raised edge 3, and the top end portion 31 of the raised edge 3 is set as a blade shape; when the ultrasonic head 2 moves to the closest distance from the mold 1 , adjust the gap h between the ultrasonic head 2 and the raised edge 3 of the mold 1 to ensure that the gap h is less than the thickness of a zipper tape 8; but the value of the gap h must be greater than 0, preferably It is larger than about 0.05mm. The above-mentioned ultrasonic generator is an instrument that generates ultrasonic waves thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com