Drum type leather gluing machine and production process thereof

A roller-type, bonding machine technology, applied in layered products, lamination devices, lamination, etc., can solve problems affecting the quality of finished products, affecting cost quality, misalignment, etc., to avoid local deformation and misalignment, and ensure bonding Quality, the effect of ensuring the quality of bonding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

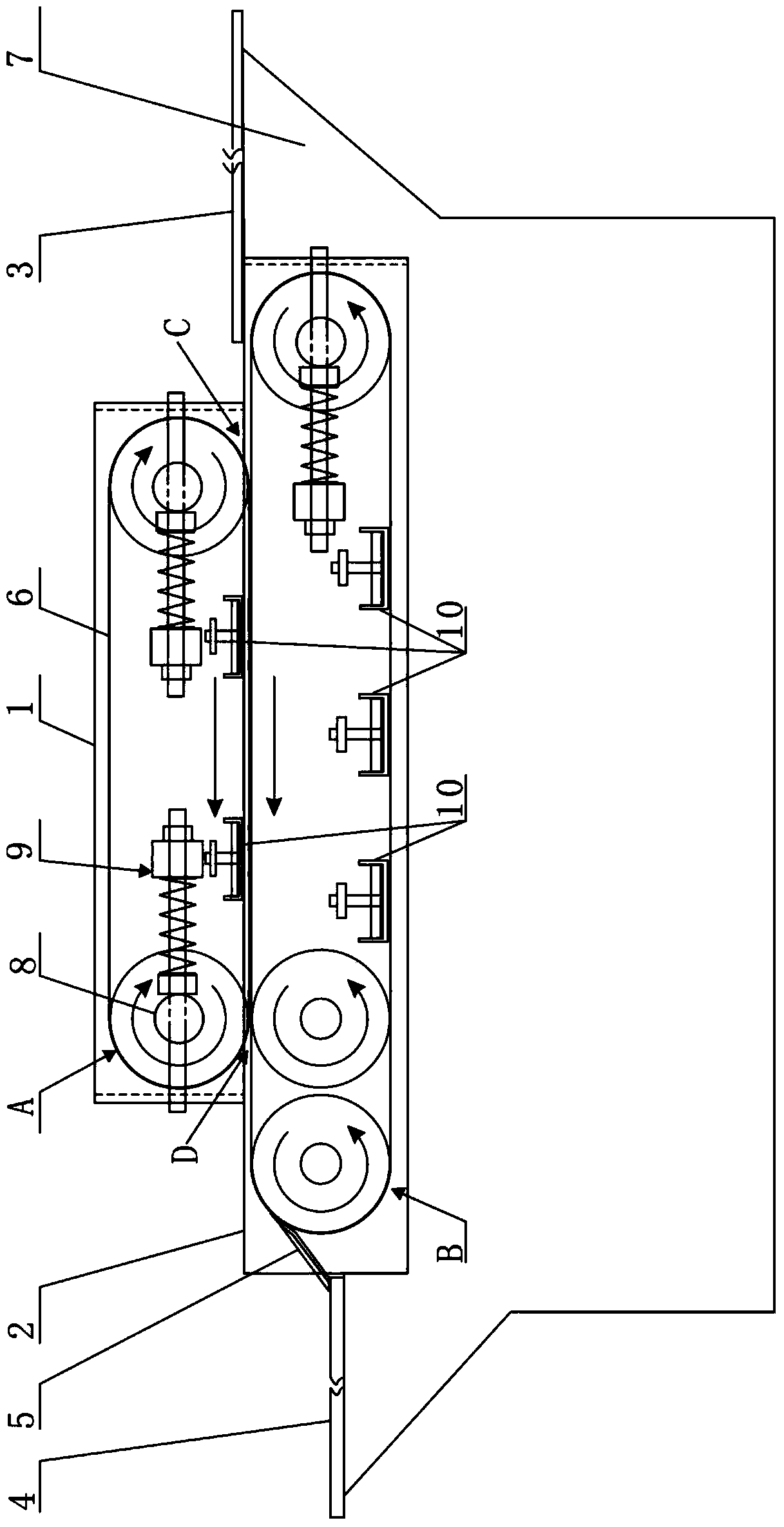

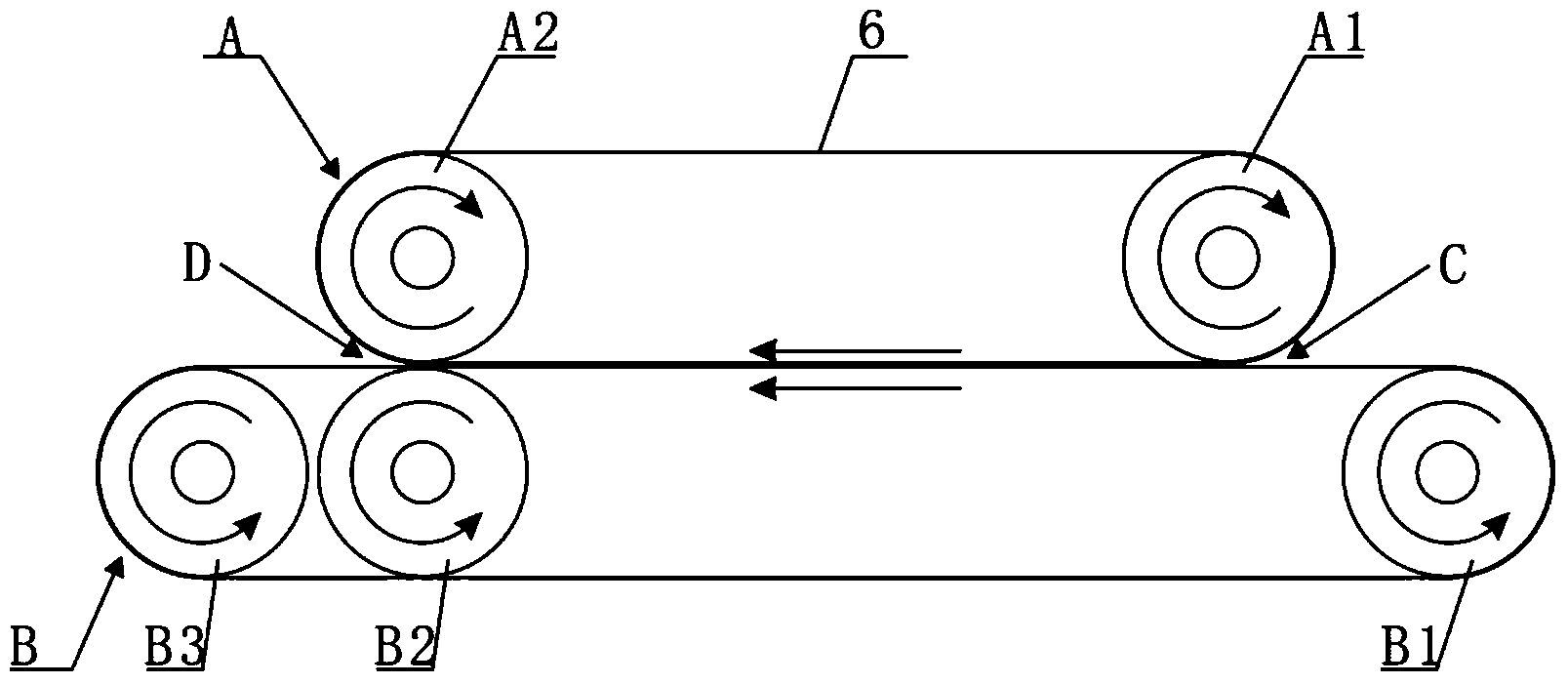

[0035] Such as figure 1 As shown, the drum-type leather bonding machine includes an upper conveyor belt A and a lower conveyor belt B installed up and down to cooperate with each other to convey and compress the leather, and a leather conveying channel is formed between the upper conveyor belt A and the lower conveyor belt B, and the leather The conveying channel height is 1.0-1.40mm. Specifically, it is 80% to 90% of the total height of the laminated leather and interlining before bonding. The upper conveyor belt A is installed on the upper frame 1, and the lower conveyor belt B is installed on the lower frame 2. The upper frame 1 is installed above the lower frame 2, and the lower frame 2 is installed above the cabinet 7.

[0036] The upper conveyor belt A includes an upper roller A1 at the upstream end and an upper roller A2 at the downstream end, and a polytetrafluoroethylene belt 6 is installed on the upper roller A1 and the upper roller A2;

[0037] The lower conveyor...

Embodiment 2

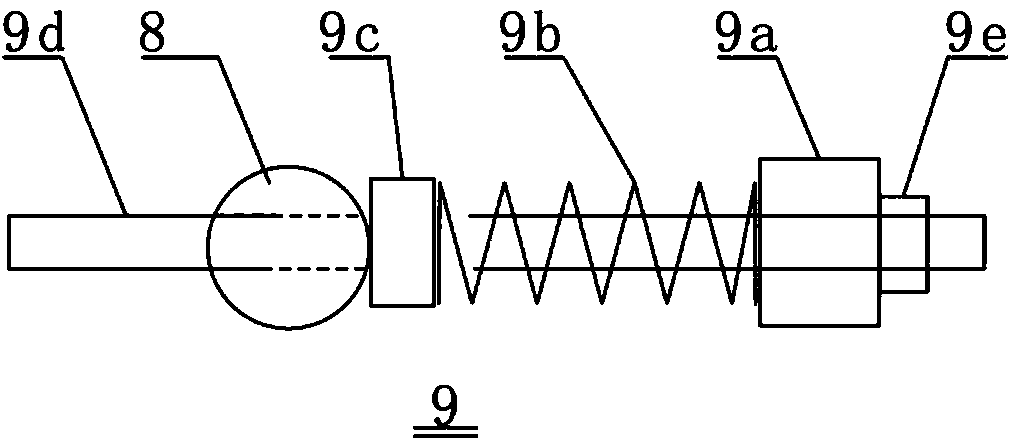

[0051] On the basis of the first embodiment, the upper roller one A1, the upper roller two A2 and the lower roller one B1 of the machine are provided with a tension mechanism 9 for adjusting the tension of the conveyor belt.

[0052] Tension mechanism 9 is connected with the rotating shaft of roller by bearing 8, and tension mechanism 9 comprises the pedestal 9a that is installed on the frame, and one side of pedestal 9a is equipped with guide pillar 9d, and guide pillar 9d passes bearing 8 and is connected with bearing 8. Sliding fit, the guide post 9d between the base 9a and the bearing 8 is equipped with a slide block 9c, the guide post 9d between the slide block 9c and the base 9a is equipped with a spring 9b, and the two ends of the spring 9b respectively abut against the slide block 9c and One end of the base 9 a and the other end of the slider 9 c abut against the bearing 8 .

[0053] The tension mechanism 9 not only provides sufficient friction for the leather and lini...

Embodiment 3

[0055] On the basis of the above-mentioned embodiments, this machine is equipped with a separation mechanism 5 that separates the leather and interlining from the lower conveyor belt B at the downstream end of the lower conveyor belt B. The separation mechanism 5 includes a support plate 5a installed on the frame to support A separation plate 5b is fixed below the plate 5a, and one end of the separation plate 5b facing the lower conveyor belt B abuts against the lower conveyor belt B, and the edge of this end is an acute angle.

[0056] Because the leather after the heating and the interlining are relatively soft, some can not be smoothly conveyed out of the lower conveyor belt B, so a separation mechanism 5 is added. Moreover, if there is residual sizing material on the lower conveyor belt B, the separating plate 5b can also play a certain cleaning role.

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com