Quick-release positioning pin structure

A technology of positioning pins and cotter pins, applied to quick-action fasteners, bolts, etc., which can solve the problems of large force, heavy weight, and large aircraft parts required for pulling out positioning pins, and achieves convenient manual operation and reduced The effect of pulling out strength and convenient quick release and positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

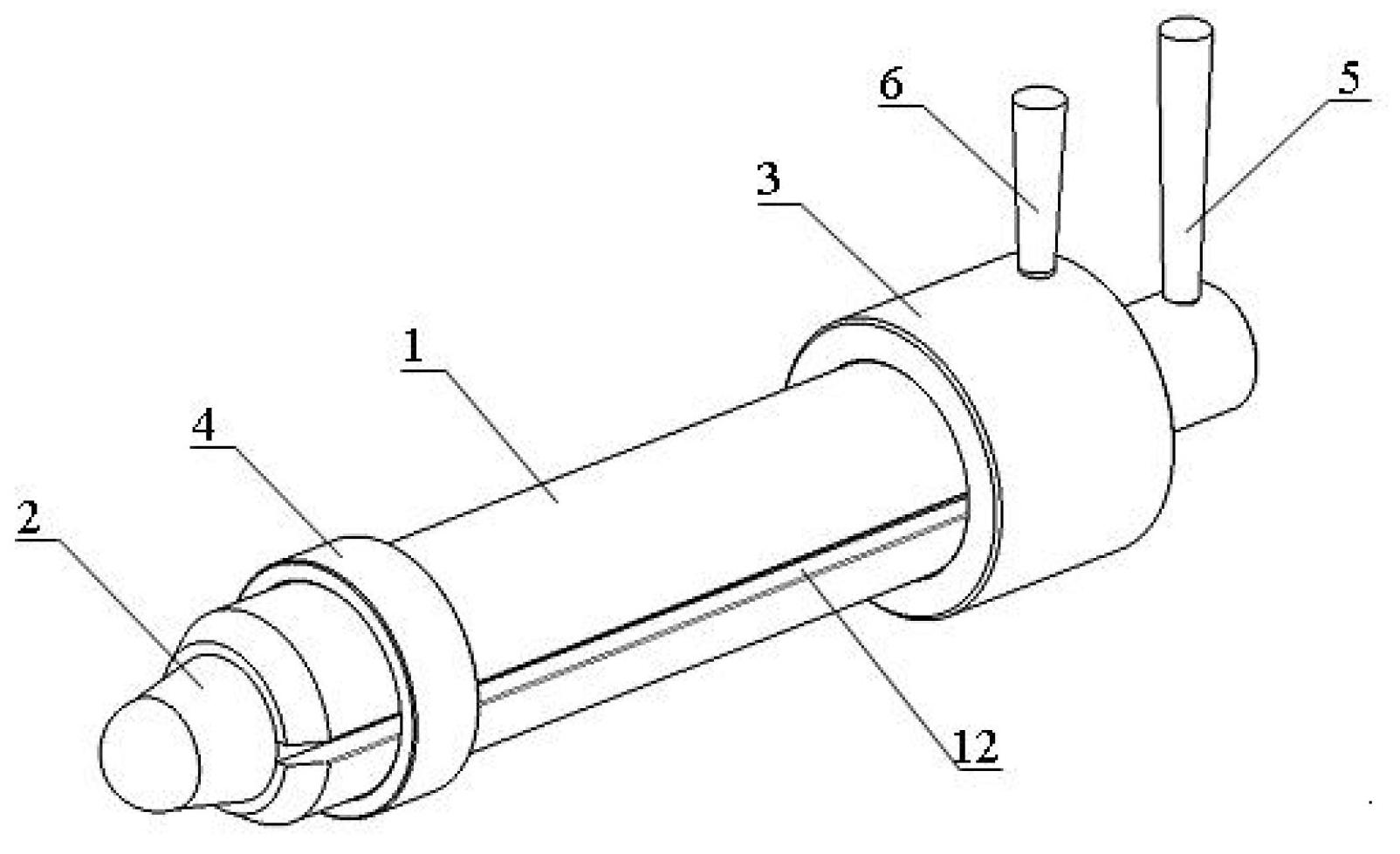

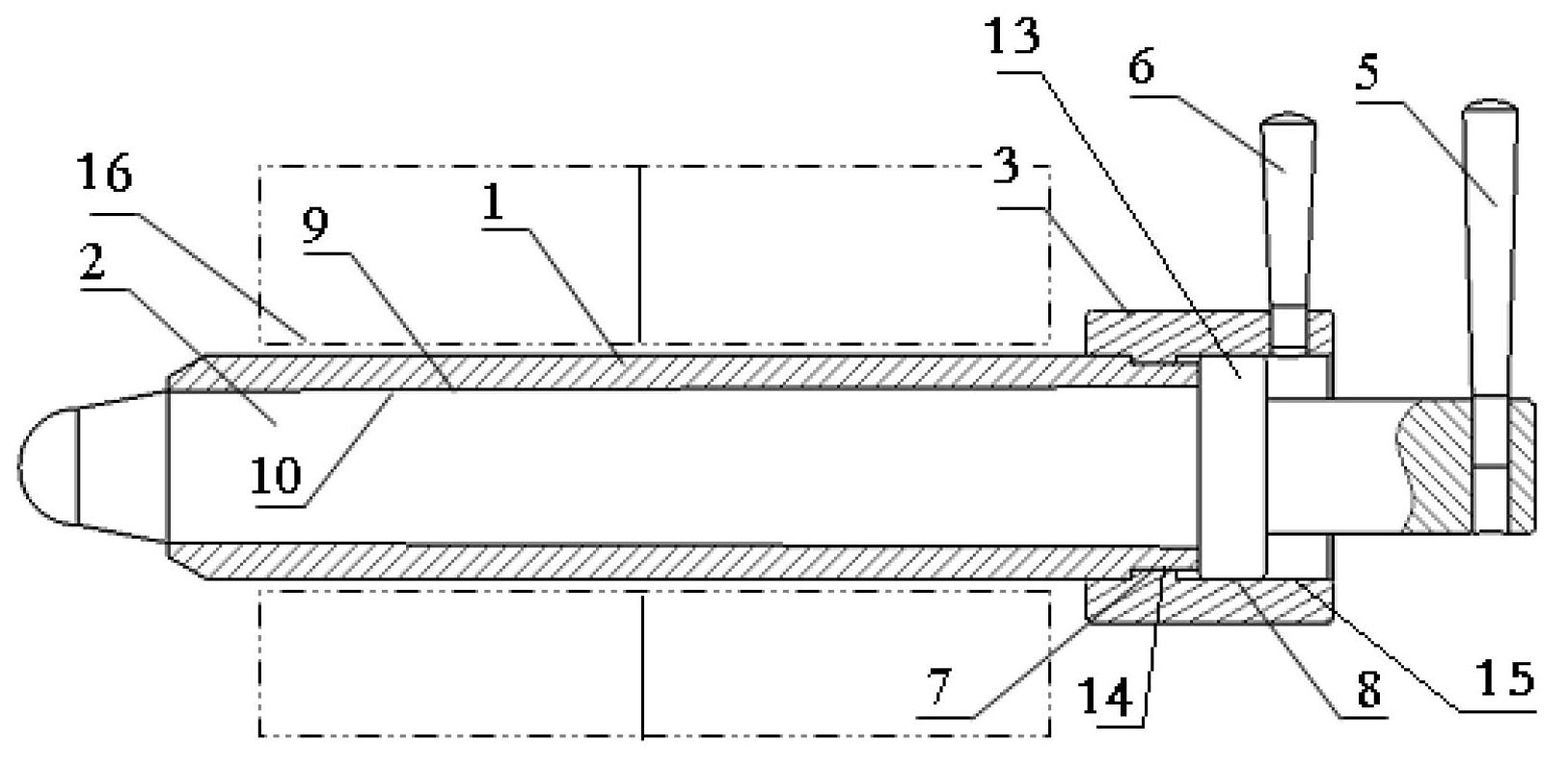

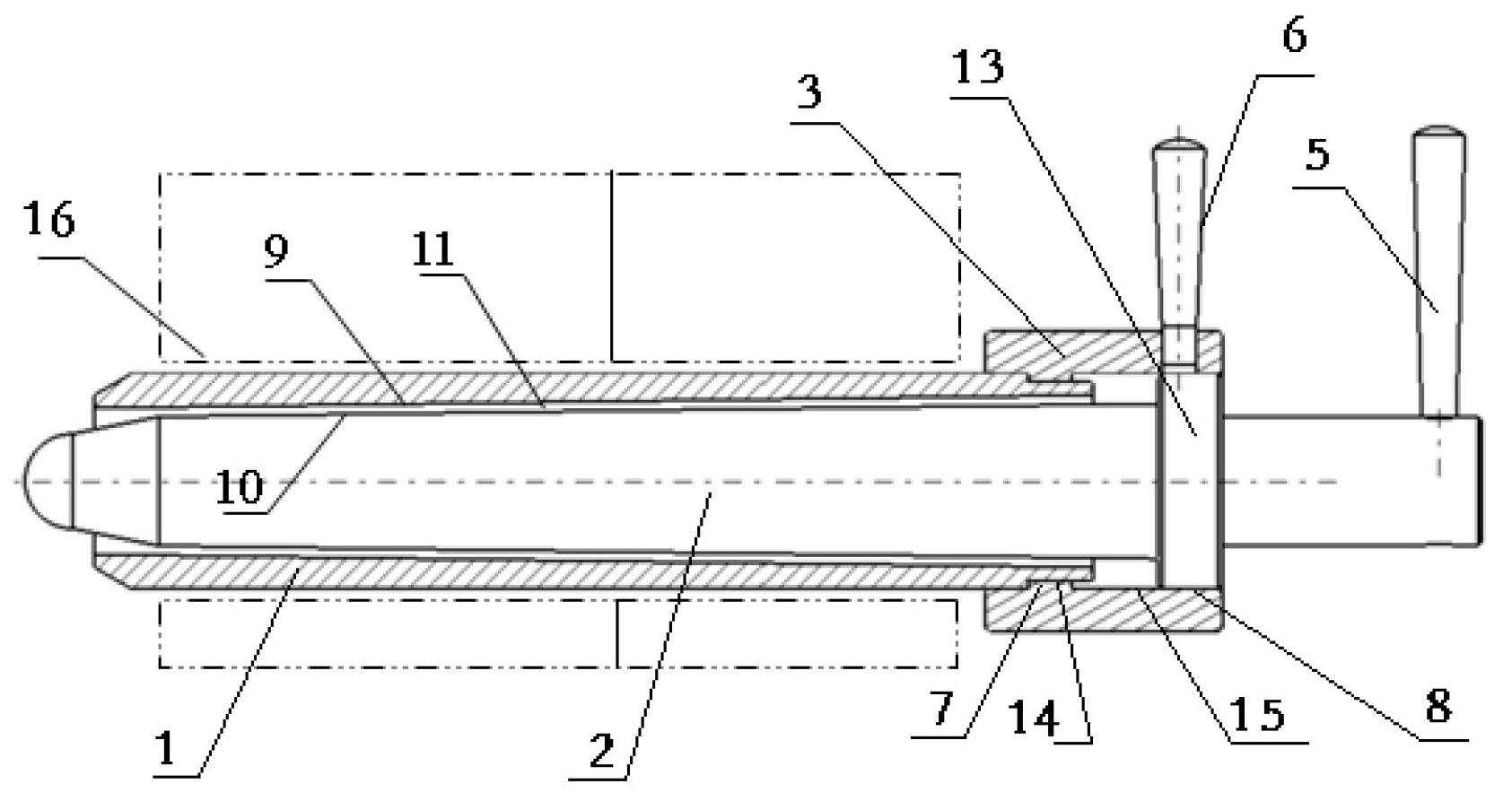

[0015] Referring to the accompanying drawings, the quick-release positioning pin of the present application is mainly composed of a positioning pin sleeve 1, a quick-release pin 2 and a quick-release screw sleeve 3. The positioning pin sleeve 1 is a cotter pin with a C-shaped opening 12, and the positioning pin sleeve 1 has a taper Inner cavity 9, one side opening end of positioning pin sleeve 1 is a tapered closing structure, to facilitate insertion in the positioning hole 16, the outside of the other side opening end of positioning pin sleeve 1 is provided with first external thread 7; The pin 2 is a solid structure with a tapered surface 10 matched with the tapered inner cavity 9 of the positioning pin sleeve 1. The front end of the quick release pin 2 is a spherical in-position structure, and the other end of the quick release pin 2 is provided with a protrusion near the end. The stepped shaft 13 has a second external thread 8 on the outer surface of the stepped shaft. It i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com