Patents

Literature

70results about How to "Reduce pullout force" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Mold/non-mode combined pulling process and device

ActiveCN102133582AImproving the process conditions of drawing formingReduce pullout forceDrawing profiling toolsPlastic propertyMechanical engineering

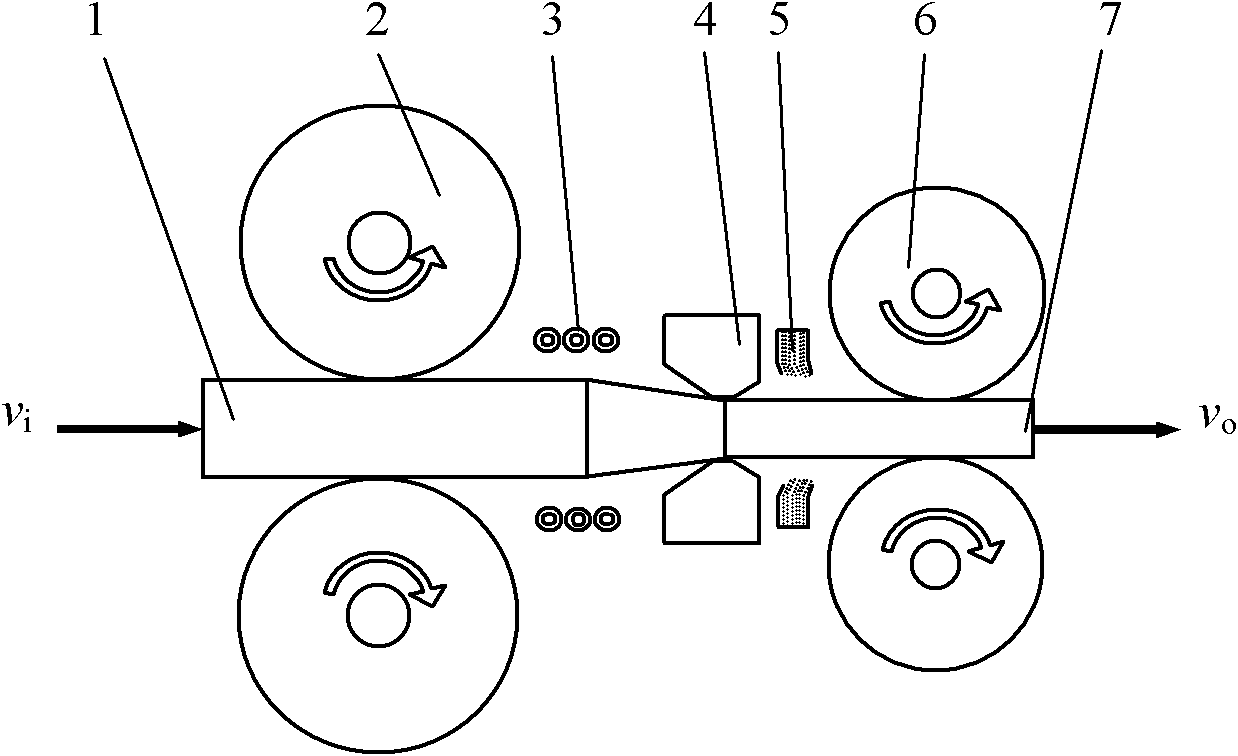

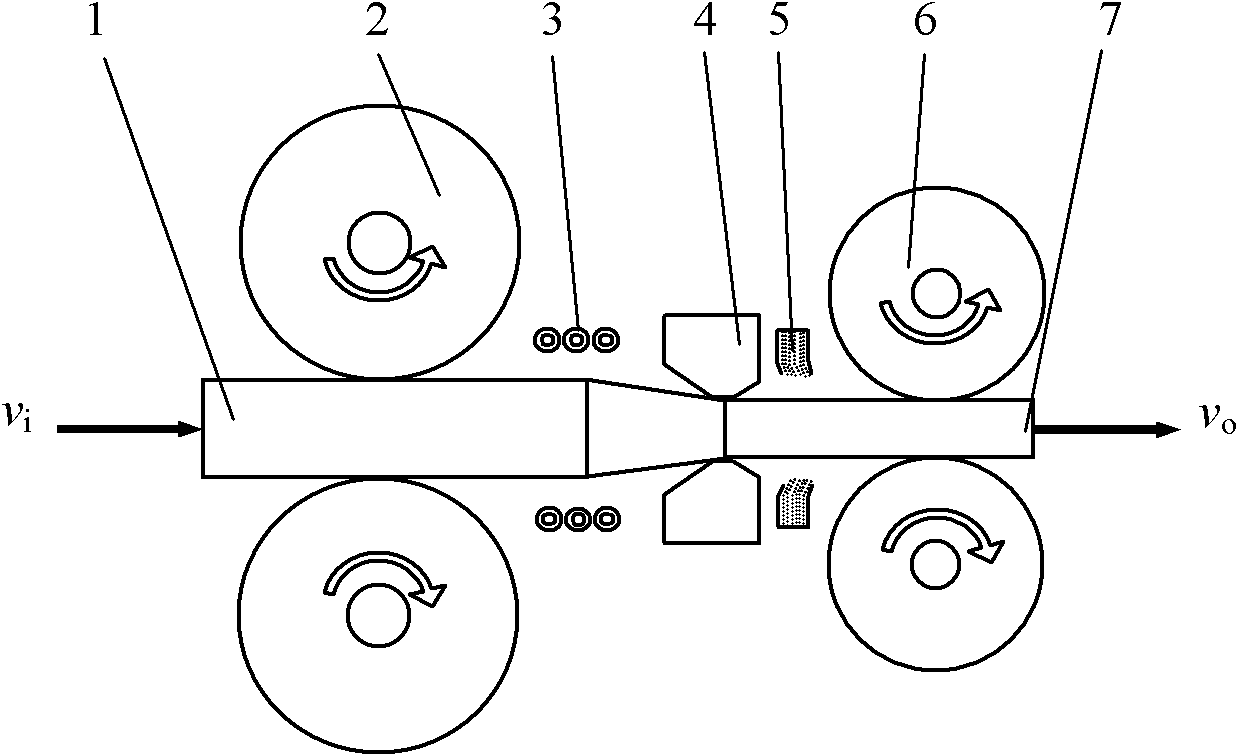

The invention belongs to the technical field of metal plastic processing, and particularly provides a mold / non-mold combined pulling process and a device. The device is characterized in that a pulling mold is directly installed between a heater and a cooling machine of a non-mold pulling device, the waste heat of non-mold pulling is utilized fully, so that the mold puling and sizing with temperature can be completed before the non-mold pulling is molded, and the surface quality is improved. In the invention, the pulling force is reduced greatly, the intermediate heat treatment or heating process of the traditional process is saved, the mold consumption is reduced, the energy resource is saved, the production cost is lowered, a high-quality metal product can be pulled and molded in short flow range, and the advantages that the deformation amount of the non-mold pulling is large, the precise of the mold pulling size is high and the like can be realized.

Owner:UNIV OF SCI & TECH BEIJING

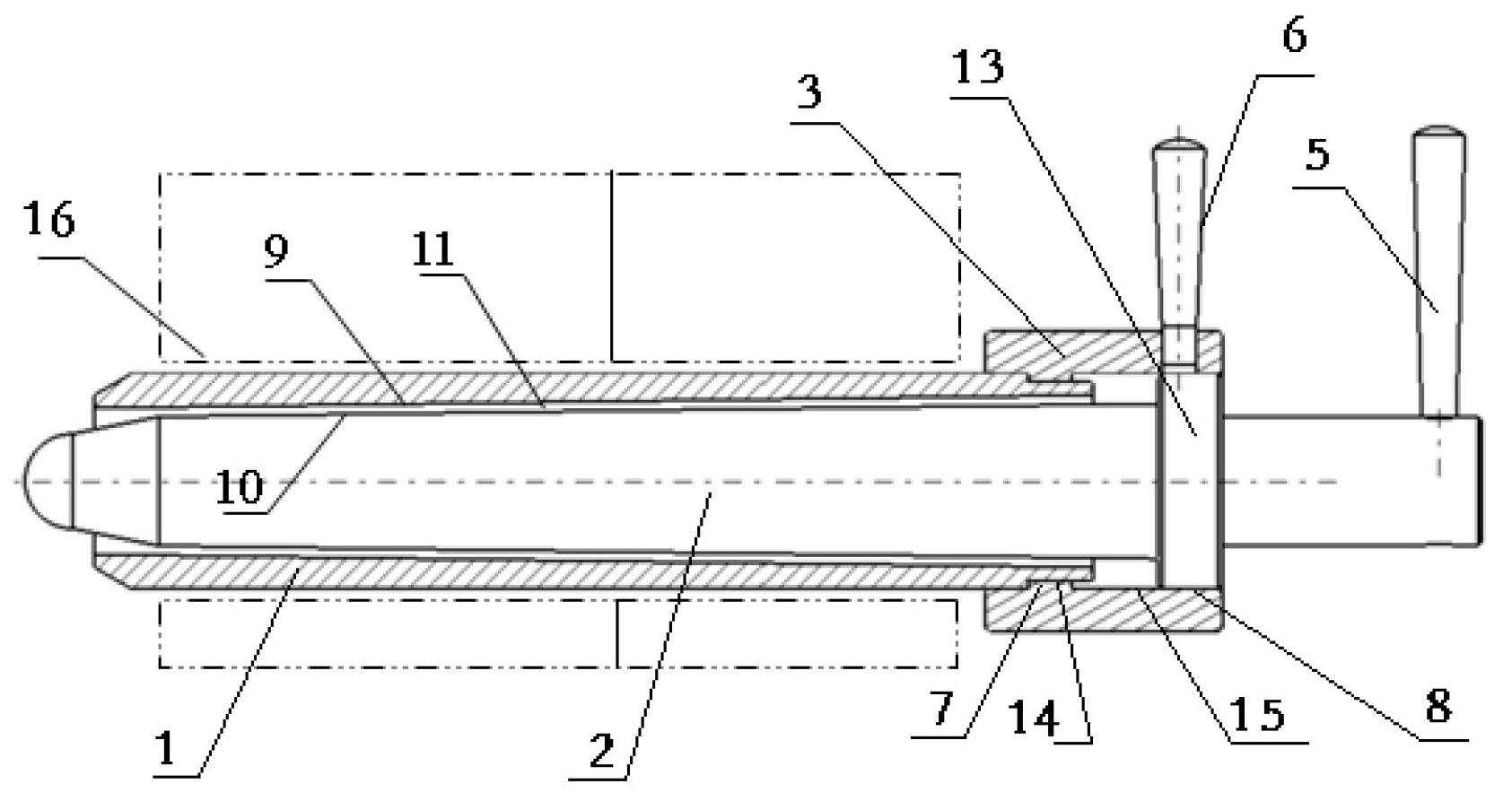

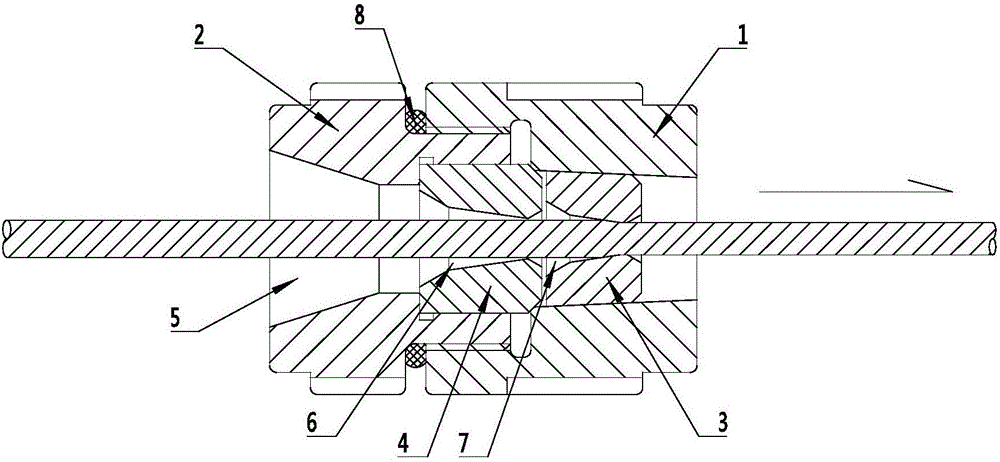

Quick-release positioning pin structure

InactiveCN102678711AOvercome only shear forceOvercome the situationSnap-action fastenersBoltsAxial forceEngineering

The invention discloses a quick-release positioning pin structure which is composed of a positioning pin sleeve, a quick-release pin and a quick-release screw sleeve. The positioning pin sleeve is in taper fitting with the quick-release pin, the quick-release screw sleeve is matched with external threads of the positioning pin sleeve and the quick-release pin respectively through internal threads, and force application handles are respectively arranged on the quick-release screw sleeve and the quick-release pin. Mechanical radial force of a butting hole site is transformed to axial force by utilizing taper, the condition that traditional cylindrical latch pin only has shearing force and friction force, the extraction strength of the cylinder pin is greatly reduced, manual operation is convenient, and a quick-release positioning function is realized.

Owner:XIAN AIRCRAFT IND GROUP

Method for producing detonating fuse or detonator delay line with small diameter and low charge linear density

The invention pertains to the technical field of explosive detonation and explosion propagation equipment and discloses a method for producing a detonating fuse or a detonator delay line with a small diameter and low charge linear density, which comprises the following steps: explosive is charged in an initial pipe body which is made from flexible metal and has wall thickness being one tenth to one third of the outer diameter of the pipe body; during the charge process, the charge linear density of the initial pipe body is calculated by the formula and then the explosive load is determined by a formula, namely M equals to rho1L1; during the continuous drawing process, the modular angle of a used mould is 7-35 degrees; the elongation coefficient of the pipe body in each drawing working procedure is controlled between 1.00 and 1.80; simultaneously, the linear speed of the drawn detonating fuse or the delay line pipe body is controlled within 85m per minute; and after the setting radial dimension is reached by drawing, suitable length is intercepted to obtain a finished product. The method realizes the continuous drawing production and can effectively and safely produce the detonating fuse or the detonator delay line with small diameter and low charge linear density. As the pipe body still has sufficient thickness after being drawn into a finished product, enough strength is ensured to restrict the internal explosive so that the explosive can form detonation and the product quality is effectively guaranteed.

Owner:UNIV OF SCI & TECH OF CHINA

Method for producing Nb3Al superconducting wire precursor through elastic plastic processing

ActiveCN104124000AImprove plastic deformation abilityReduce work hardeningCable/conductor manufactureNiobiumHigh energy

The invention discloses a method for producing an Nb3Al superconducting wire precursor through elastic plastic processing. The method for producing the Nb3Al superconducting wire precursor through the elastic plastic processing comprises assembling an aluminum bar, a niobium tube and a copper tube to obtain a copper, niobium and aluminum composited bar; performing electric plastic drawing machining on the copper, niobium and aluminum composited bar through an electric plastic drawing device to obtain a subgroup element; performing drawing machining through the electric plastic drawing device again after the subgroup element is assembled and squeezed to finally obtain a multi-core Nb3Al superconducting wire precursor. The method for producing the Nb3Al superconducting wire precursor through the elastic plastic processing has the advantages of slowing down processing hardening, greatly improving the material plastic deformation capability, solving the problem that a wire breaks down during drawing due to the facts that the niobium and the aluminum are large in melting point difference and accordingly effective stress relief annealing cannot be performed, meanwhile shortening the production period and reducing production costs due to the fact that high-energy electric pulses are introduced during wire machining.

Owner:西部超导材料科技股份有限公司

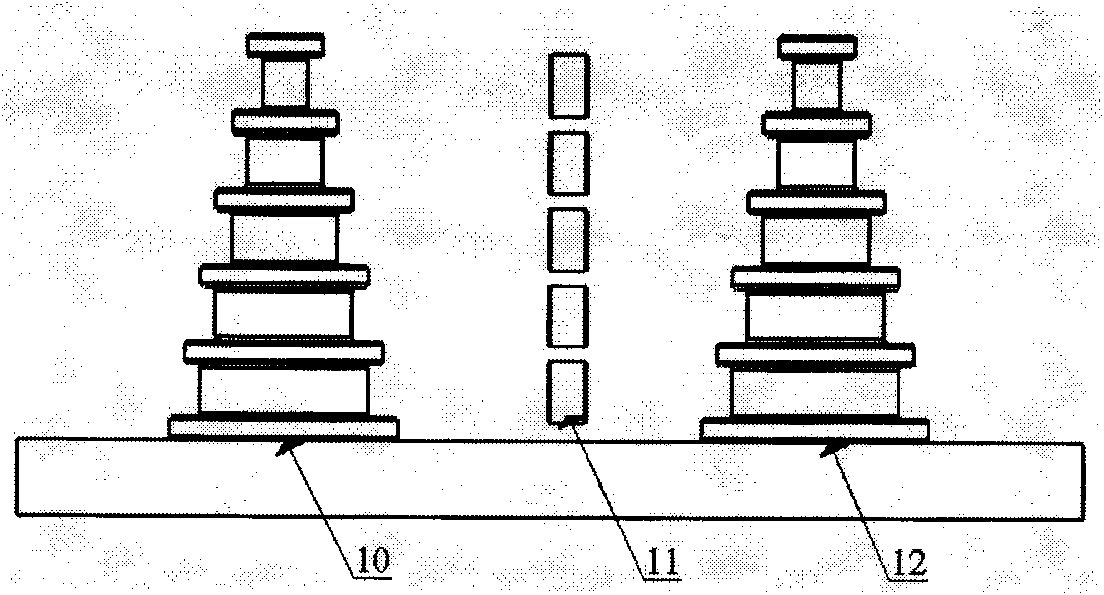

Porous electric heating recyclable anchorage device combined type component and construction method using same

InactiveCN104264670AHigh extraction rateStrong decimation rateBulkheads/pilesHeat fusionPetroleum engineering

The invention discloses a porous electric heating recyclable anchorage device combined type component and a construction method using the same, relates to the combined component providing temporary support for rock and soil anchorage engineering and the construction method using the same and aims at providing the porous electric heating recyclable anchorage device combined type component which enables steel strands to be conveniently, efficiently and rapidly recycled and the construction method for recycling the steel strands using the component. The porous electric heating recyclable anchorage device combined type component comprises a first external locking plate and a second locking plate; a first inner core supporting plate and a second inner core supporting plate are arranged between the first external locking plate and the second locking plate; a first electric heating melting high-strength plastic plate and a second electric heating melting high-strength plastic plate are arranged between the first inner core supporting plate and the second inner core supporting plate; a current heating plate is arranged between the first inner core supporting plate and the second inner core supporting plate; the above components are fixedly connected through connecting parts; a clamping device is arranged between the external locking plate and the inner core supporting plate; springs sleeve two ends of the connecting parts; a lead is connected to the current heating plate.

Owner:CENT RES INST OF BUILDING & CONSTR CO LTD MCC GRP +1

Drawing forming device and method for tin-bismuth alloy welding wire

Owner:JIANGXI UNIV OF SCI & TECH

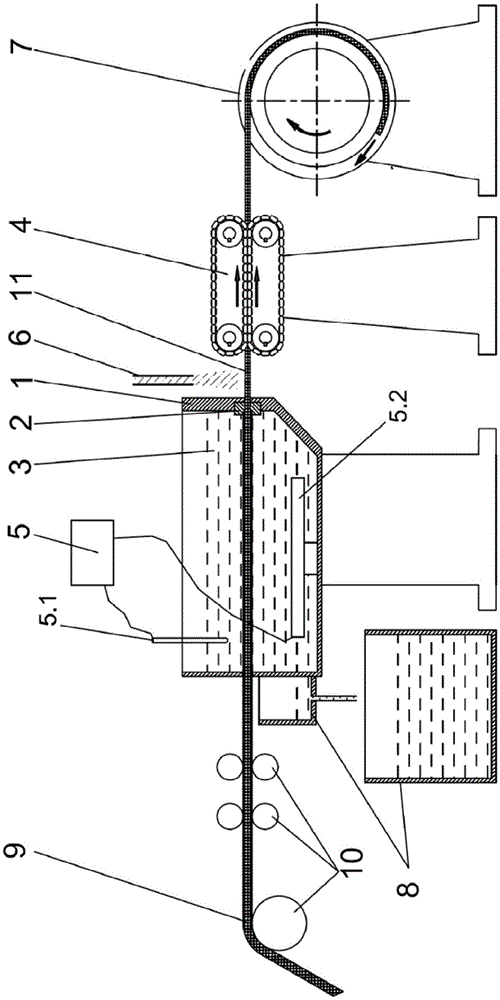

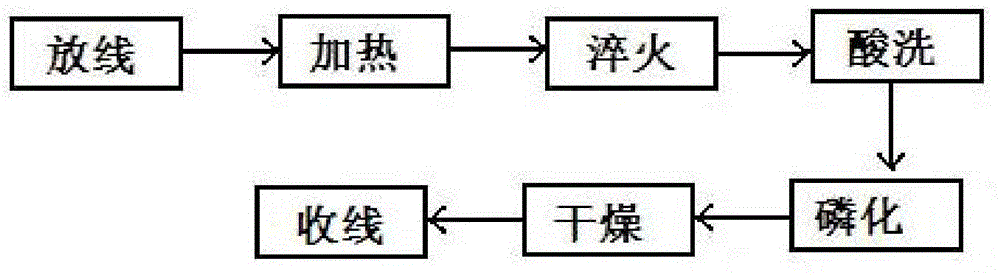

Thermal treatment technique of steel wire

ActiveCN102912109AImprove heat utilizationNo pollution in the processFurnace typesMetallic material coating processesThermal treatmentQuenching

The invention discloses a thermal treatment technique of a steel wire, comprising the following steps of: paying-off the steel wire by a pay-off rack; heating the steel wire by natural gas; putting the heated steel wire in a quenching bath for quenching; washing by water; putting the steel wire a pickling tank and then a phosphating tank; drying in a drying baker; and finally taking up. According to the invention, the whole thermal treatment line is free of pollution, clean and environment-friendly, the utilization rate of the thermal treatment heat is high, and energy is saved.

Owner:JIANGSU SAFETY STEEL WIRE ROPE

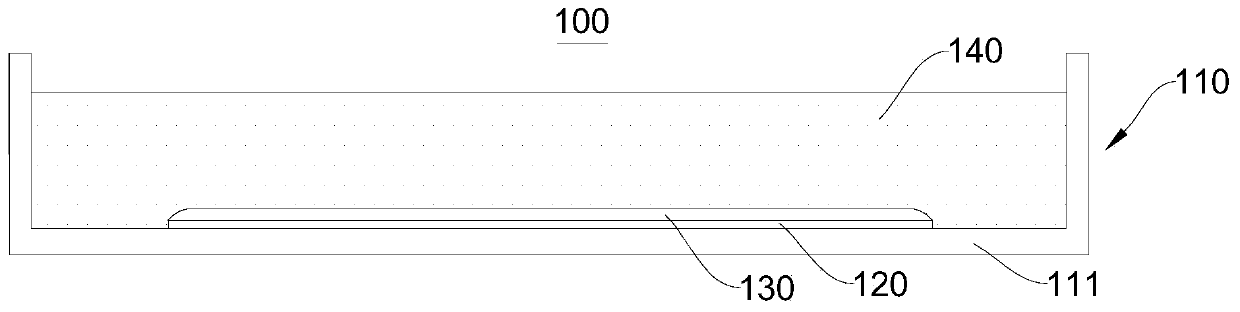

3D printing device and method

ActiveCN110802838AIncrease success rateReduce stickingManufacturing platforms/substrates3D object support structures3d printPolymer science

The invention discloses a 3D printing device. The 3D printing device comprises a resin tank, a printing platform and a light source system. A hard transparent plate is arranged on the bottom face of the resin tank, a transparent gel layer is arranged on the hard transparent plate, the printing platform is located on the upper portion of the resin tank, a light source of the light source system isarranged on the lower portion of the hard transparent plate, and the gel layer contains silicone oil or fluorocarbon oil. The invention further provides a 3D printing method. According to the 3D printing device and method, drawing force during releasing can be obviously reduced, and meanwhile, conventional all photosensitive resin on the market can be compatible.

Owner:江西迈亚科技有限公司

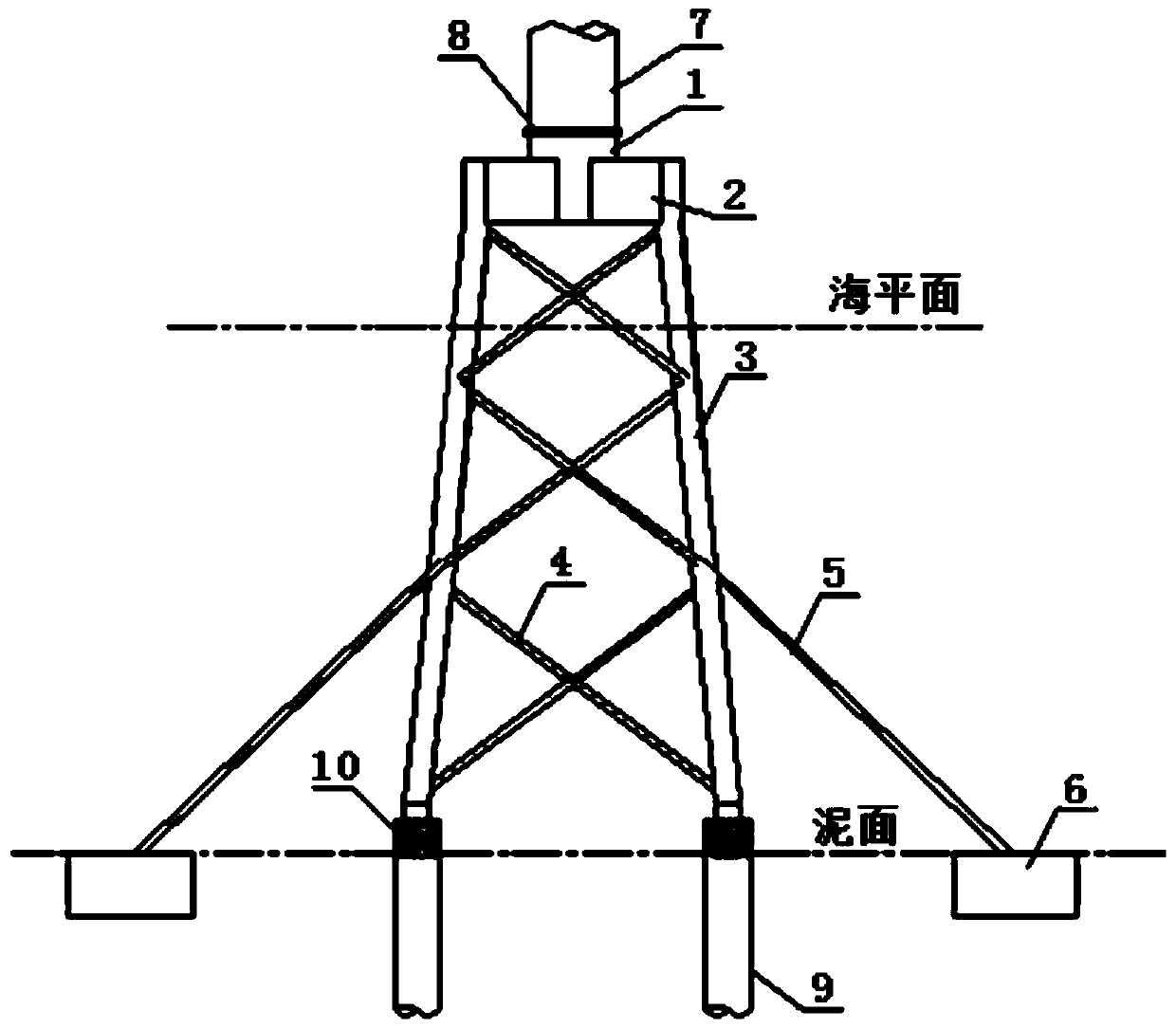

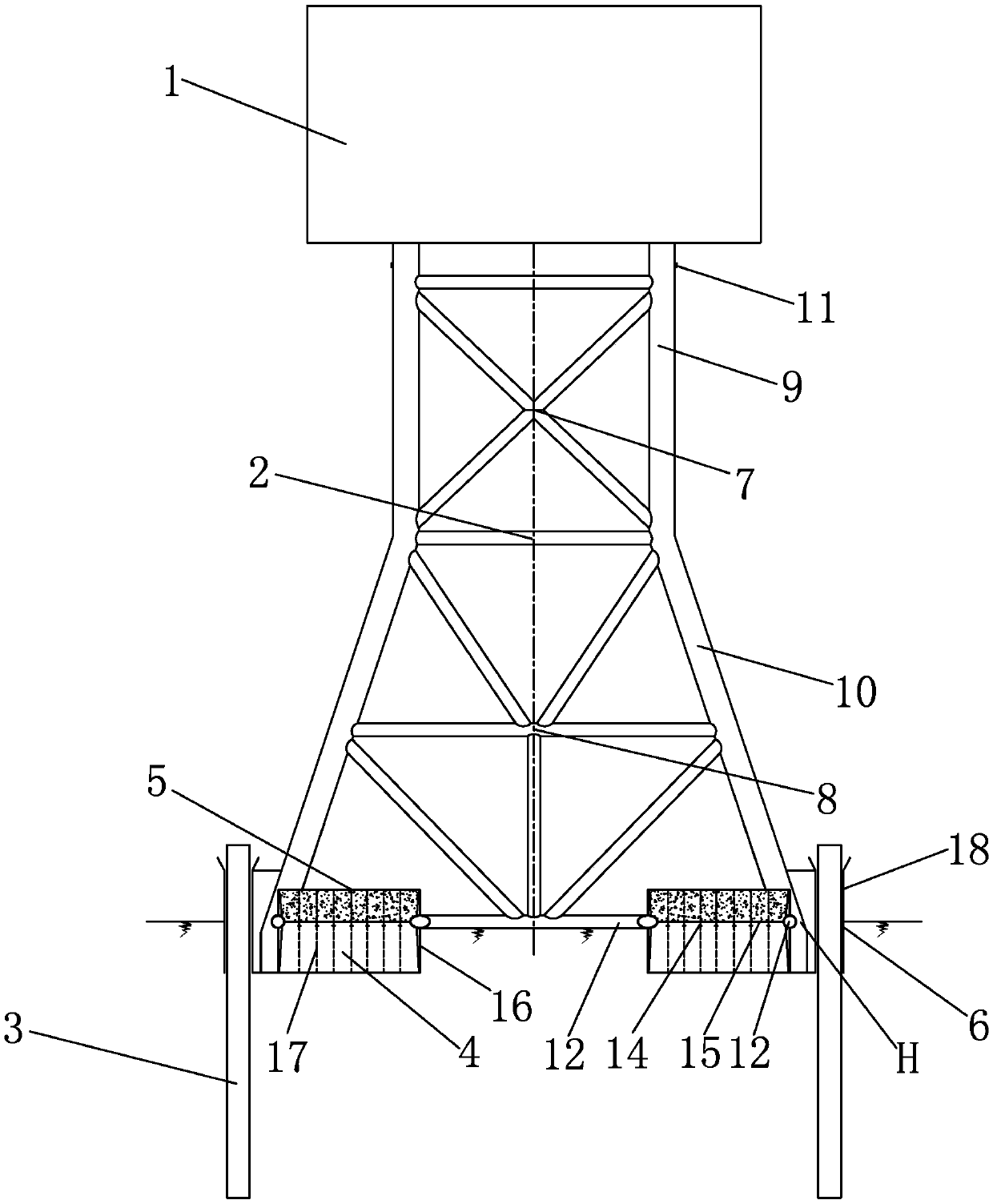

Offshore wind power combination foundation

PendingCN109853609AIncrease lateral stiffnessImprove horizontal carrying capacityFoundation engineeringElectricityHorizontal force

The invention relates to an offshore wind power combination foundation. The offshore wind power combination foundation includes a guiding pipe frame, steel pipe piles, suction cylinders, and steel cables. The offshore wind power combination foundation is composed of the guiding pipe frame, the steel pipe piles, the suction cylinders, and the steel cables; the guiding pipe frame and the suction cylinders are connected by the steel cables, the steel cables can exert their high and strong tensile strength, the lateral rigidity of the combined foundation is increased, the guiding pipe frame bearsa vertical load, a fan horizontal load and a wave current force borne by the guiding pipe frame are transmitted to the suction cylinders through the steel cables for sharing, since the suction cylinders are dispersed and embedded into surface layer soil and have a large contact area with a surface layer soil foundation, horizontal force resistance of surface soil can be fully exerted, the horizontal bearing performance of a foundation pile can be improved, the basic anti-overturning capability is improved, the drawing force of main legs of the guiding pipe frame is reduced, thereby reducing the distance between the main legs of the guiding pipe frame and the cross section of a rod piece, and the basic cost and construction difficulty are reduced. The suction cylinders can employ negative pressure sinking, and the construction difficulty is small.

Owner:CHANGJIANG SURVEY PLANNING DESIGN & RES

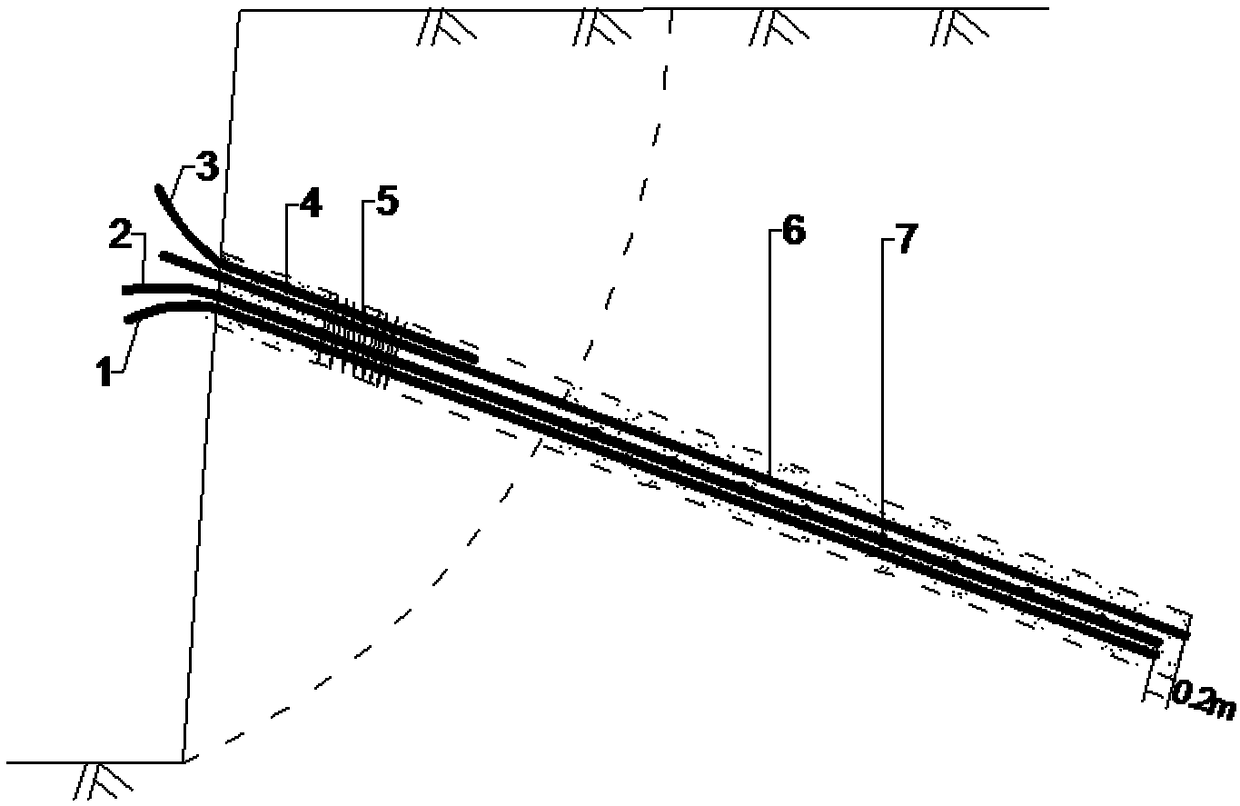

Convenient and rapid pressure grouting method adopting anchor rod

The invention relates to a convenient and rapid pressure grouting method adopting an anchor rod, and belongs to the technical field of foundation engineering. The method comprises the steps that 1, drilling is carried out in a preset position; 2, a primary grouting pipe, a secondary grouting pipe, an exhaust pipe and the anchor rod are wrapped tightly with a woven bag and are inserted into a drilling hole, wherein the distance between the top of the woven bag and the drilling hole is 2.0-3.0 m, the distance between the bottoms of the primary grouting pipe and the secondary grouting pipe and the bottom of the drilling hole is 150-250 mm, and in the length of a anchorage section, a plurality of slurry outlets are formed in the side wall of the secondary grouting pipe, and the opening end atthe bottom of the secondary grouting pipe and the slurry outlets are sealed through adhesive tape; 3, the diameter of the tightly-wrapped woven bag is the same as the diameter of the drilling hole; 4,hole sealing is carried out; 5, primary grouting is carried out; and 6, secondary high-pressure grouting is carried out. According to the convenient and rapid pressure grouting method adopting the anchor rod, effecting grouting and reinforcement of backfilling soil, loose soil and soft clay bodies can be ensured to be realized through the anchor rod, and the anti-pulling force of the anchor rod can be guaranteed. The method has the advantages that waste can be reutilized, general adaptability is achieved, the manufacturing cost is low and the construction is simple and convenient.

Owner:DALIAN UNIV OF TECH

Vibration drawbench

The invention relates to a drawbench, in particular to a vibration drawbench, which solves the problem that the present drawnbench is difficult to disassemble tightening components which are closely tightened. The drawbench comprises a mandrel and a claw which is connected with the mandrel, wherein the end part of the mandrel is provided with a vibrator with adjustable vibration frequency. When in use and when the vibration frequency is adjusted to a resonant frequency range of a part to be disassembled, the part to be disassembled produces a serious resonance, the friction force between the parts to be disassembled is greatly reduced, and at the same time force is applied to the mandrel of the drawbench, the parts to be disassembled can be easily separated. Against for the overlarge friction force between the parts to be disassembled, a way that a vibrator is installed on a drawbench mandrel to compulsorily vibrate the parts to be disassembled is adopted, so the friction force between the parts to be disassembled is greatly reduced, and the disassembling difficulty of the original drawbench is solved.

Owner:TAIYUAN COAL GASIFICATION GROUP

Mobile phone glass press-key manufacturing process

InactiveCN101335781ALower surface energyReduce pullout forceElectric switchesTelephone set constructionsKey pressingAdhesive

A mobile phone glass press-key manufacturing process includes: heating a glass layer for 5-20 minutes at the temperature of 40-100 DEG C, and then adhering a keystoke body and the glass layer with patterns through adhesive. Because the manufacturing method provided by the invention heating the glass layer before adhering the keystoke body and the glass layer, water, organics, powder dust and the like substance absorbed at eth surface of the glass layer are removed, and the intrinsic surface energy of the glass layer is recovered, accordingly reinforcing the drawing force between the keystoke body and the glass layer, so that the joint between the keystoke body and the glass layer is firm enough to reach the test requirement.

Owner:BYD CO LTD

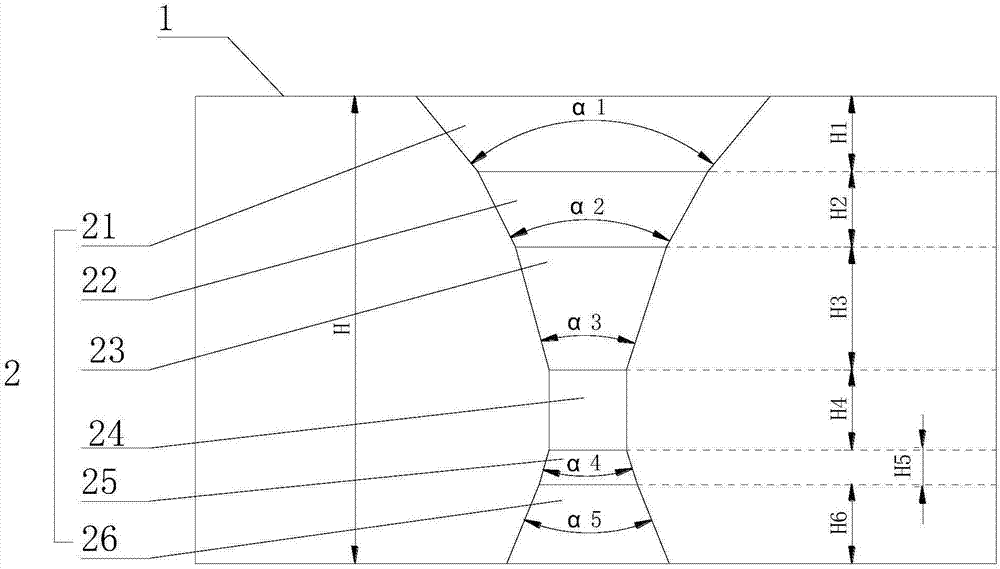

Steel cord wire-drawing die

The invention provides a steel cord wire-drawing die. The steel cord wire-drawing die comprises a die body; a wire drawing hole is formed in the die body; the conical angle of an inlet zone is alpha 1; the conical angle of a lubrication zone is alpha 2; the conical angle of a sizing zone is alpha 3; the conical angle of a decompression zone is alpha 4; the conical angle of an outlet zone is alpha 5; and alpha 1 is greater than alpha 2; alpha 2 is greater than alpha 5; alpha 5 is greater than alpha 3; alpha 3 is equal to alpha 4; the height of the die body is H; the height of the inlet zone is H1; the height of the lubrication zone is H2; the height of a working zone is H3; the height of the sizing zone is H4; the height of the decompression zone is H5; the height of the outlet zone is H6; H3 is greater than H4; H4 is greater than H6; H6 is greater than H2; H2 is equal to H1; and H1 is greater than H5. According to the steel cord wire-drawing die, during wire drawing, stability of a metal wire is increased; the metal wire can transit smoothly, so that the metal wire is not easily broken; thickness of the product is uniform; plastic deformation and elastic deformation of the metal wire are reduced; the conical angle of the working zone is equal to that of the decompression zone, so that reduction and uniform distribution of the friction force are favorably realized during a drawing process of the metal wire; abrasion of a die hole of the wire-drawing die is lowered; heat generated by friction of the metal wire and the die can be dissipated in time; and the service life of the die is prolonged.

Owner:杨飞

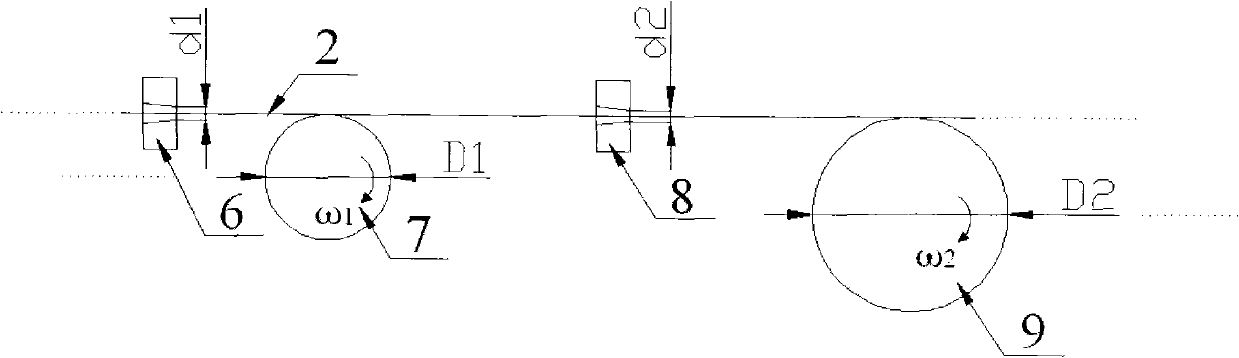

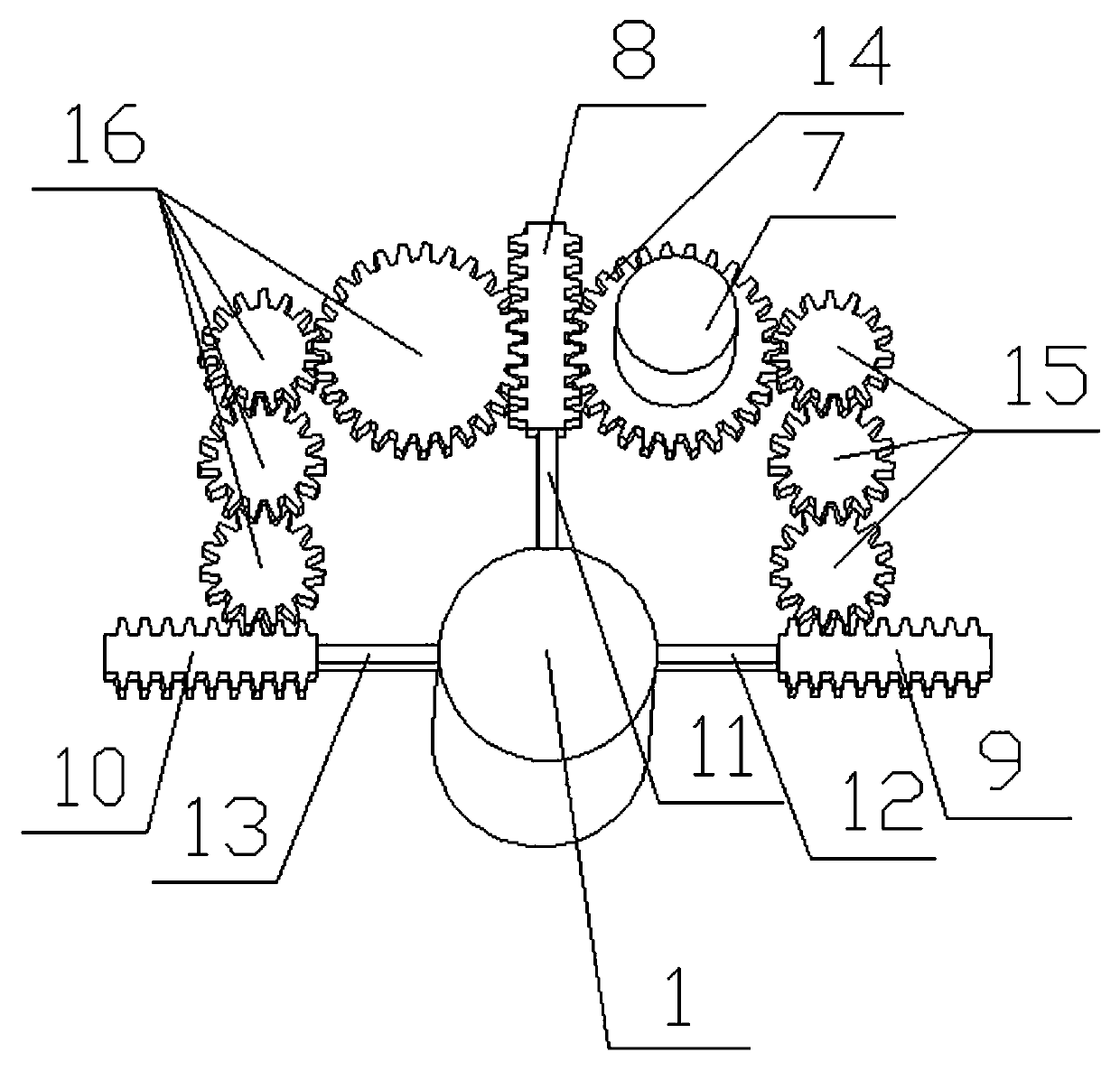

Symmetrical four-roller die drawing method for regular-hexagon-section titanium wires

The invention discloses a symmetrical four-roller die drawing method for regular-hexagon-section titanium wires, which has the advantages of reducing the processing passes and the intermediate annealing passes, reducing the drawing force and the device driving power, reducing the material and energy source loss, enhancing the finished product rate and is very wide in application range. Based on the comprehensive advantages of the conventional rolling and fixed die drawing processing method, two rollers of a roller type die having a V-shaped cavity with an 120-degree inner angle and two rollers of a plane roller type die are used for forming a combination in which the four rollers are vertical in the front-rear direction and are crossed symmetrically in the horizontal direction, or two combinations each comprising the above four rollers and in which the rollers are crossed vertically in the front-rear direction and are crossed symmetrical in the horizontal direction are formed; the combinations are used for the roller die drawing in the processing of regular-hexagon-section titanium wires; the symmetrical four-roller die drawing method for regular-hexagon-section titanium wires is applicable to processing titanium and titanium alloy regular-hexagon-section wires which are high in surface quality, finished product rate, efficiency and single-deck weight.

Owner:西安中泰新材料科技有限公司

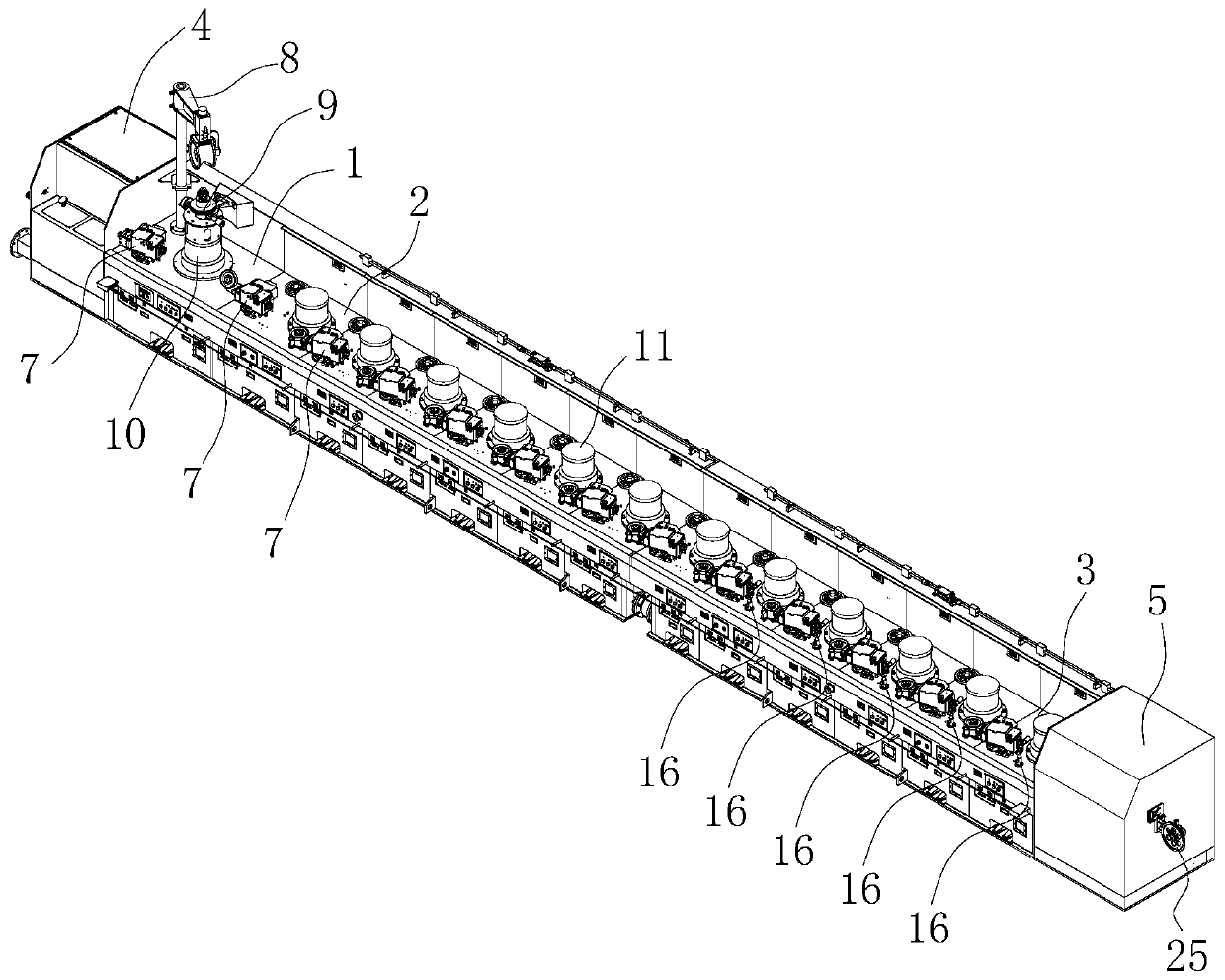

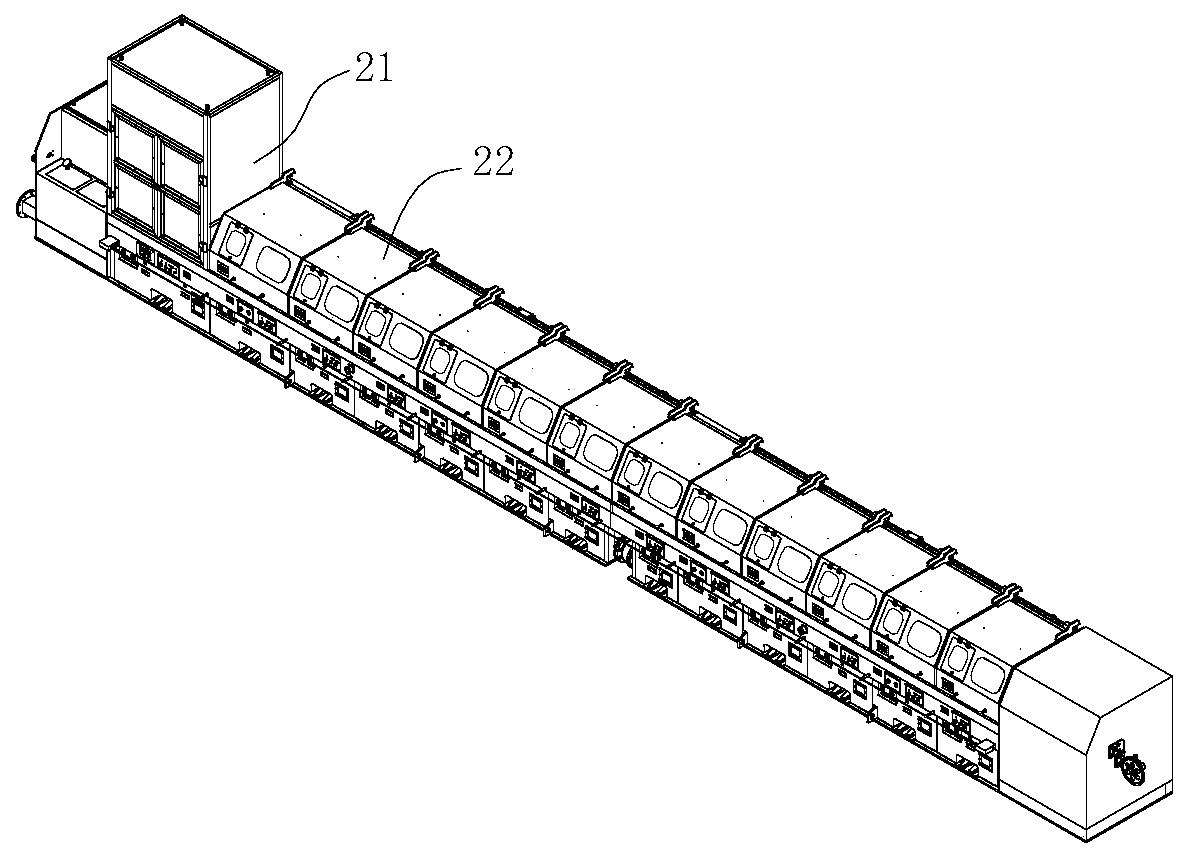

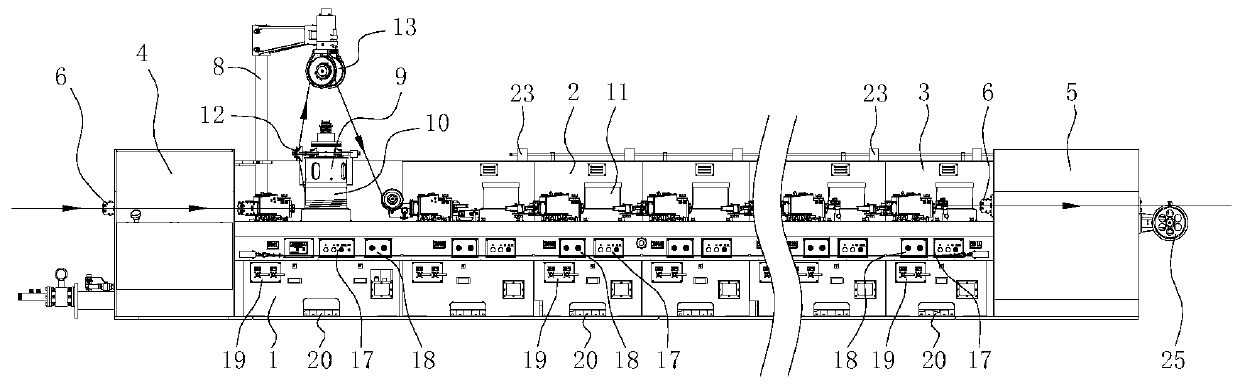

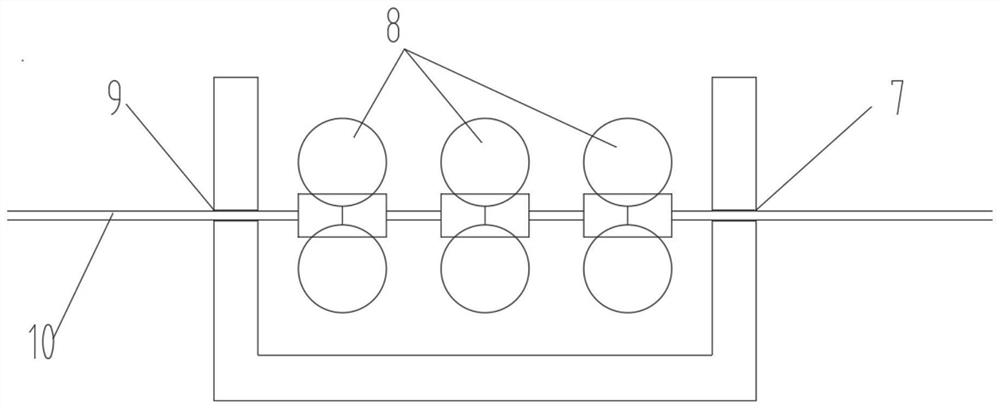

Loop type wire drawing machine

PendingCN110756605AReduce the degree of impactGuaranteed timelinessDrawing diesWater tanksWire drawing

The invention provides a loop type wire drawing machine. The loop type wire drawing machine comprises a first machine table, a plurality of second machine tables and a third machine table which are sequentially arranged from a wire inlet end of the drawing machine to a wire outlet end of the drawing machine, a water tank and an electric control cabinet, wherein the water tank is arranged at one end of the drawing machine, and the electric control cabinet is arranged on the other end of the drawing machine; the wire inlet end of the drawing machine and the wire outlet end of the drawing machineare both provided with herringbone rollers; a mold box, a hanging bracket device, a wire pulling device and a first winding drum are arranged on the first machine table; mold boxes, second winding drums and guide wheel devices are arranged on the second machine tables; and a mold box and a second winding drum are arranged on the third machine table. According to the loop type wire drawing machine, the multi-stage winding drums and the mold boxes are arranged, and the mold boxes are capable of lubricating and cooling metal wires, so that the drawing force of the metal wires between every adjacent winding drums is reduced, the drawing speed is increased, the drawing quality is improved, and the production efficiency is improved.

Owner:GUIZHOU AEROSPACE NANHAI SCI & TECH

Pressure wire drawing die good in lubrication

InactiveCN106513451ASolve the problem of longevitySolve quality problemsDrawing diesPressure wireEngineering

The invention discloses a pressure wire drawing die good in lubrication. The pressure wire drawing die comprises a die base and a pressing bolt detachably arranged on the die base. A conical wire drawing die cavity is formed in the die base and internally provided with a conical wire drawing die body. The wire drawing die body is provided with a high-pressure lubrication cavity and a wire drawing hole. A pressure die is arranged in the pressing bolt and provided with a conical hole. The pressure die is arranged between the pressing bolt and the wire drawing die body. The pressing bolt is provided with a lubricating agent cavity used for containing a lubricating agent. The lubricating agent cavity communicates with the high-pressure lubricating cavity through the conical hole. According to the pressure wire drawing die good in lubrication, the steel wire surface friction force is reduced, the steel wire drawing force is reduced, and accordingly the purpose of improving the production efficiency is achieved.

Owner:鹤山恒基钢丝制品有限公司

Film coating device for steel stranded steel wire drawing and using method

InactiveCN104525597ALow priceAbundant resourcesExtrusion cleaning devicesTectorial membraneHigh pressure water

The invention relates to a film coating device for steel stranded steel wire drawing. The film coating device comprises a box body, a cleaning mechanism and a film coating mechanism, wherein a partition plate is installed in the box body so as to divide the box body into the cleaning mechanism located at the wire inlet end of the left side and the film coating mechanism located at the wire outlet end of the right side of the box body. High-pressure water can thoroughly remove tiny particles on the surface of a rolled steel wire, and a good foundation is laid for follow-up film coating work. After the rolled steel wire passes through the film coating mechanism, a protective film is formed on the surface of the rolled steel wire and is used for protecting the rolled steel wire against scratching and enabling the surface of the rolled steel wire to be evenly coated with an adhesive agent carrier in the rolled steel wire drawing process, the coating of the adhesive agent is loose and porous and has rough surface, and the capacity of attaching to a dry powder lubricant of the coating is very high. Therefore, friction force between the small rolled steel wire and a mold is reduced, drawing force is reduced, energy consumption is reduced, and the service life of the mold is prolonged. The adhesive agent carrier produces physical absorption, has the advantages of being simple in operation and short in proposal time, and adhesive agent resources are rich and low in cost.

Owner:天津日吉科技有限公司

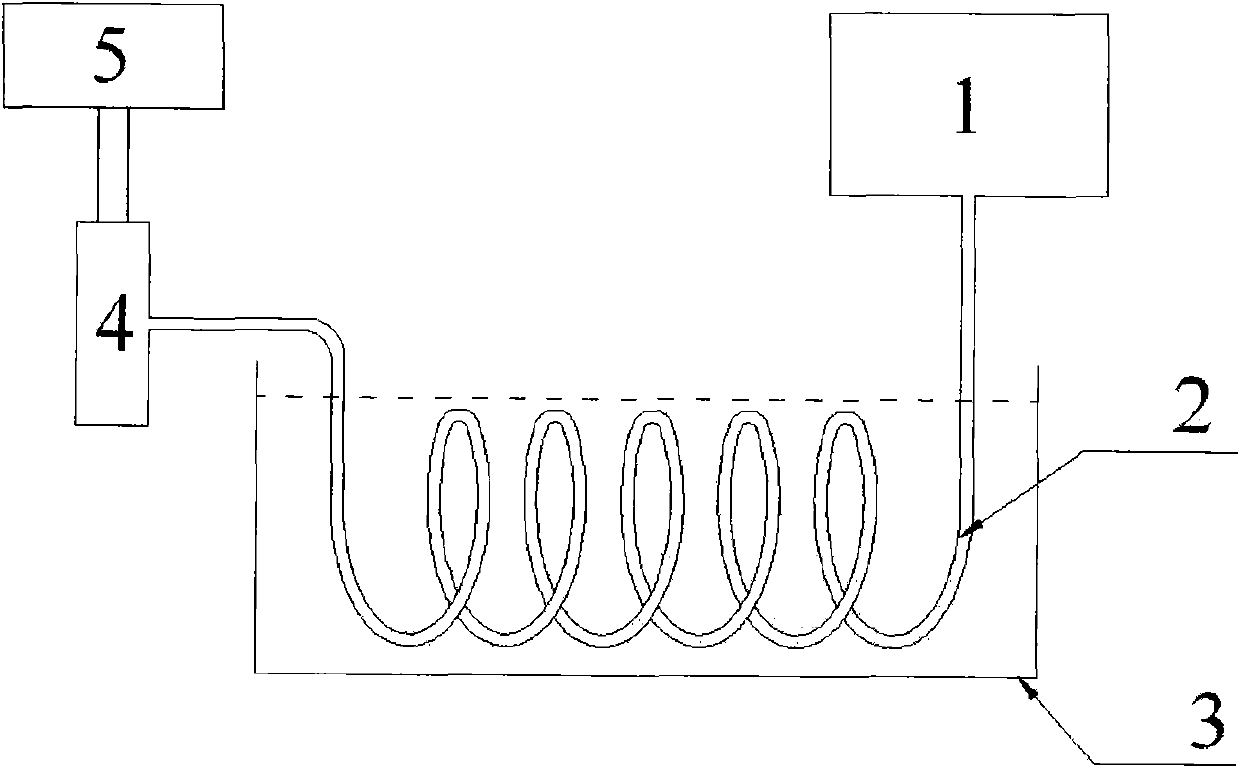

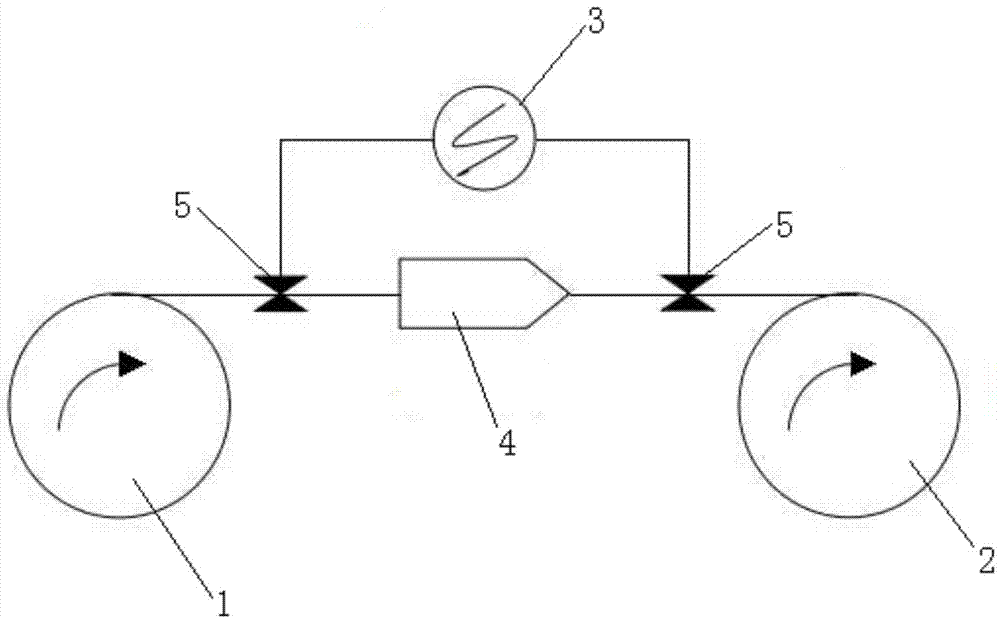

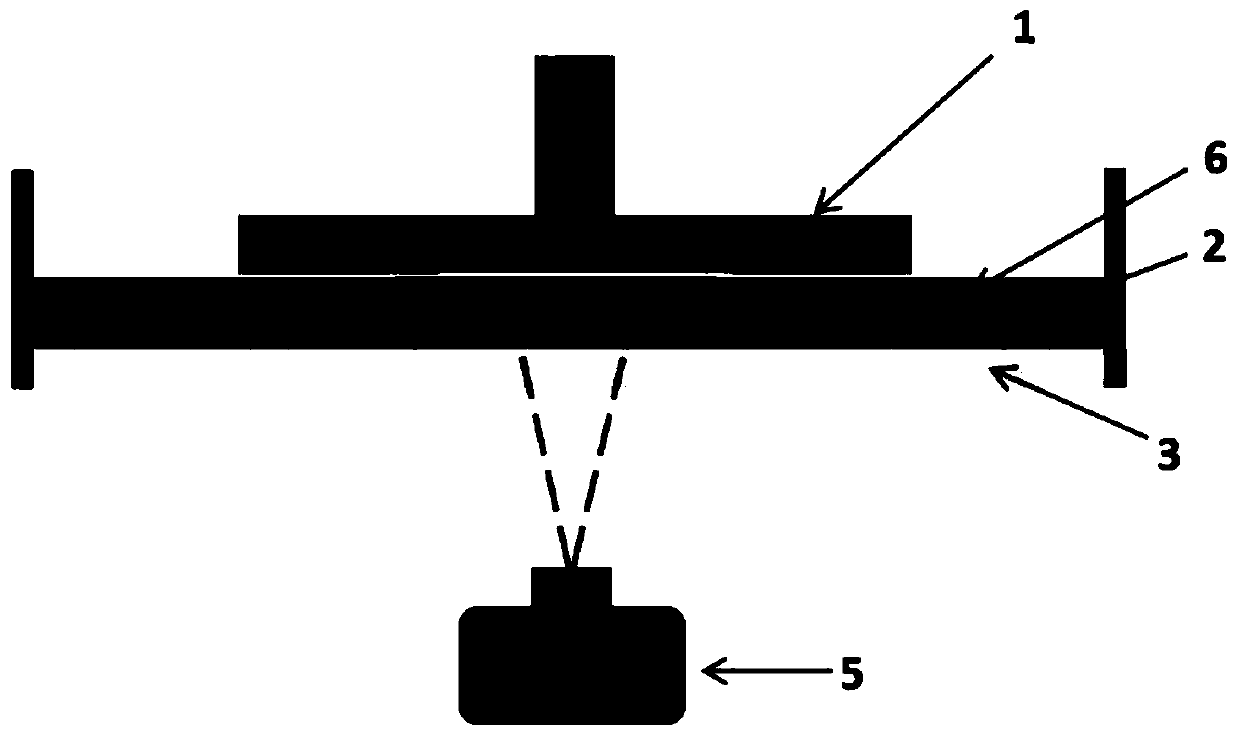

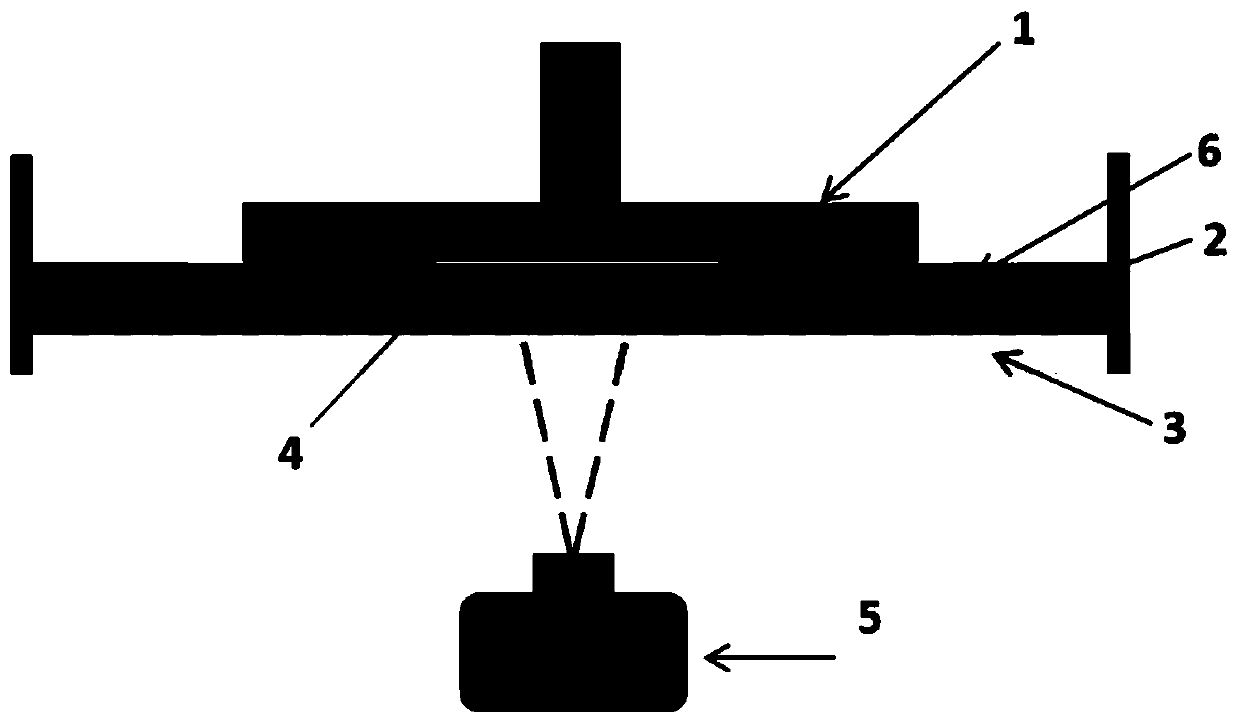

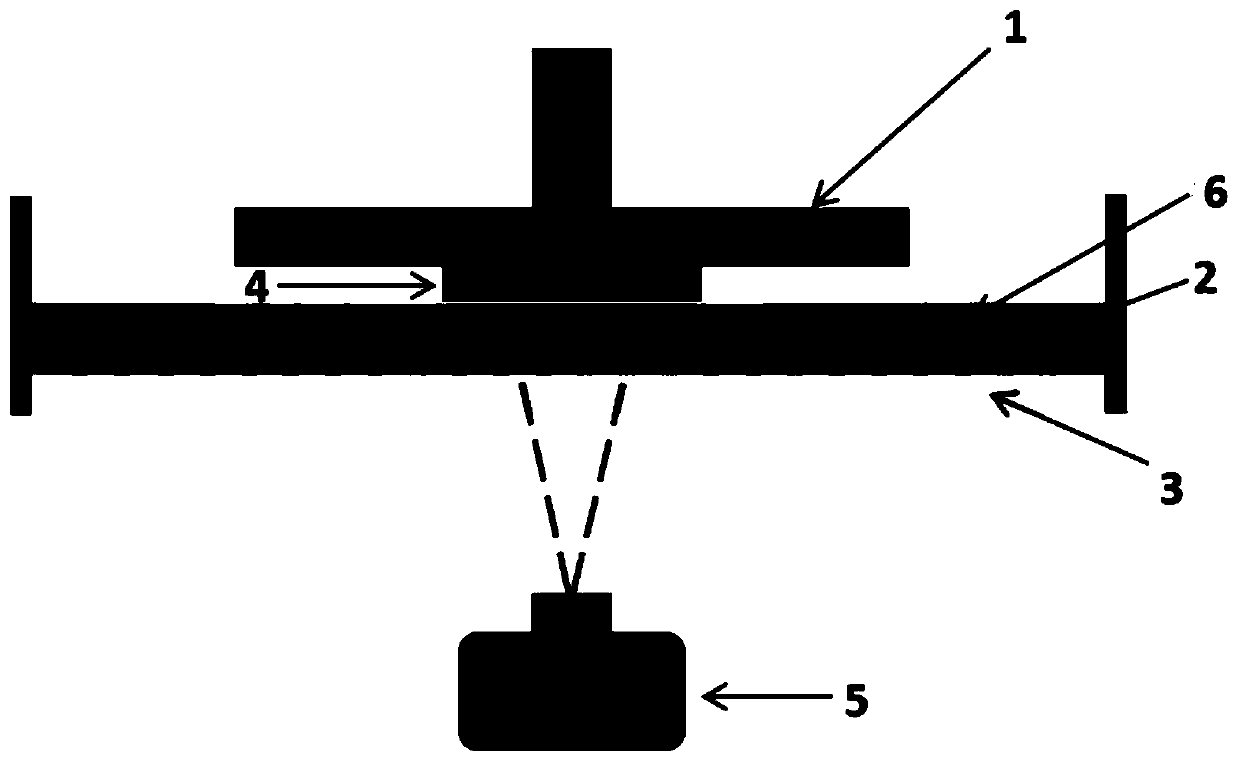

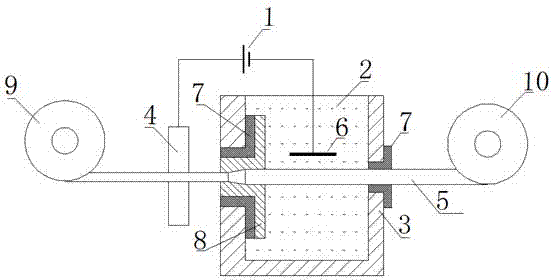

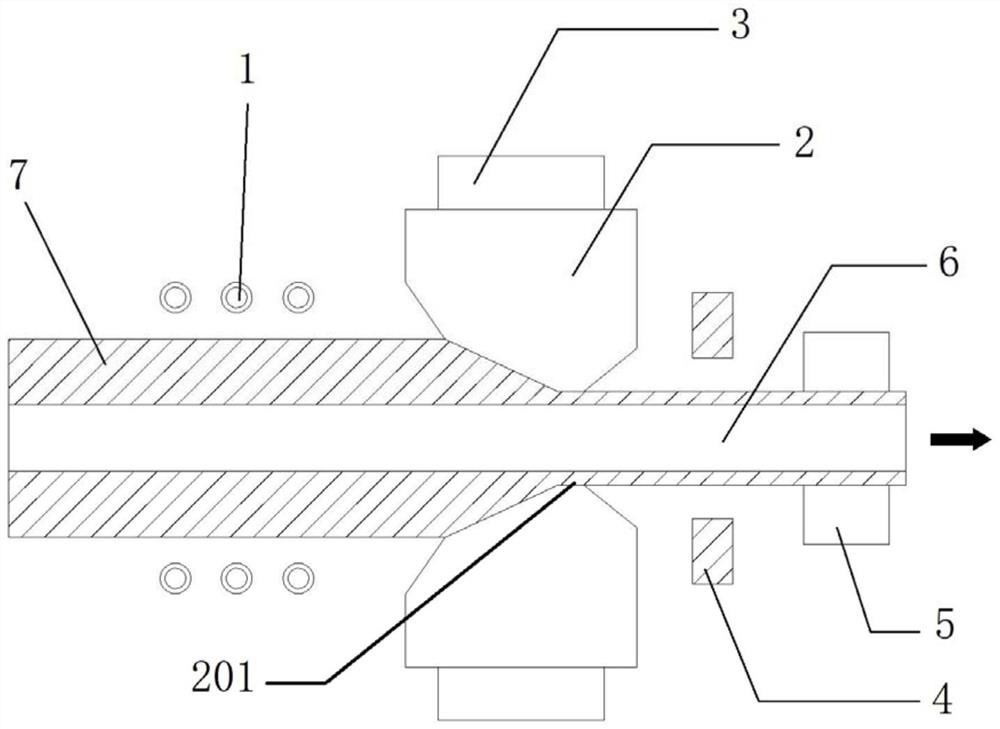

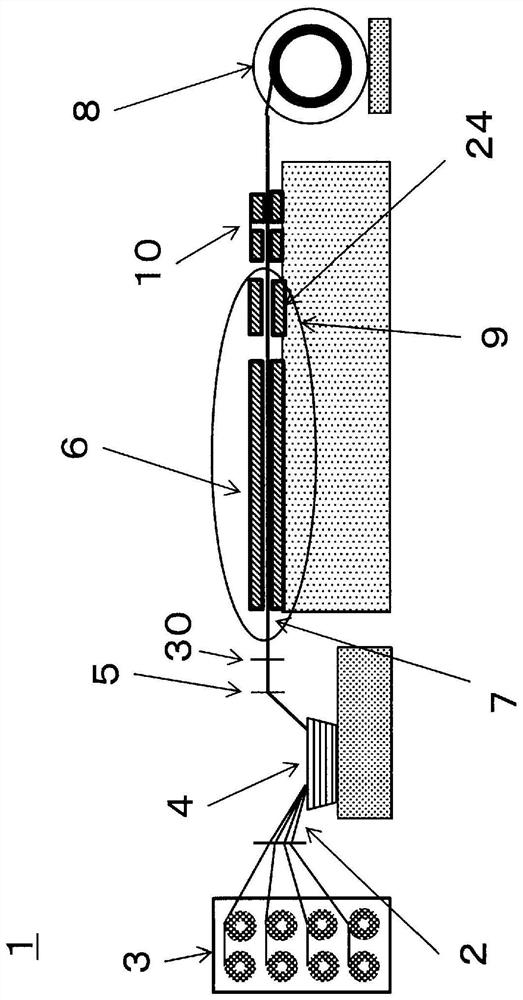

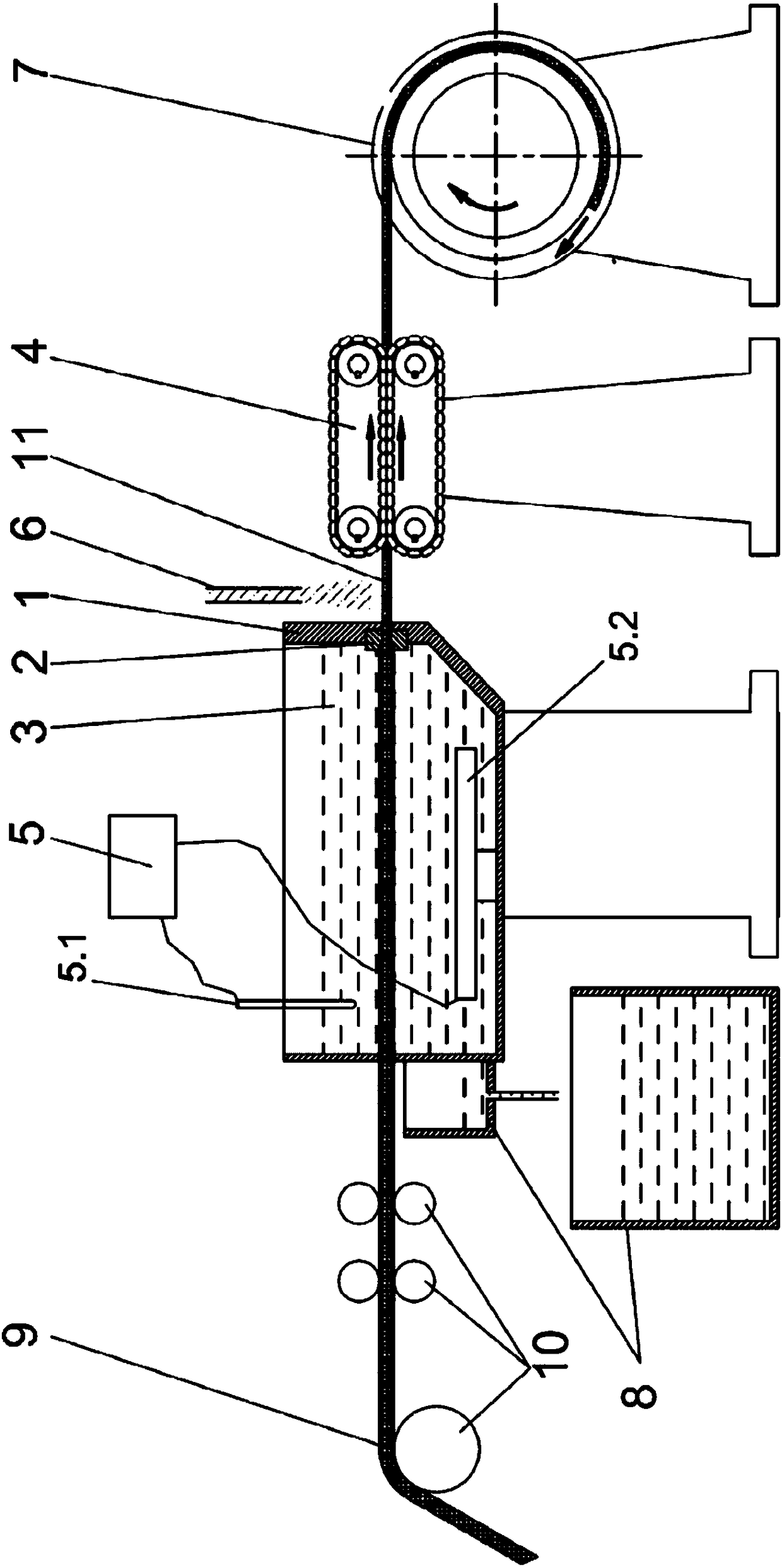

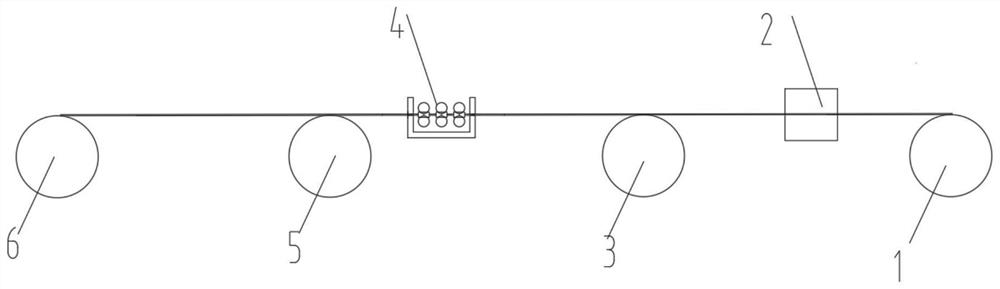

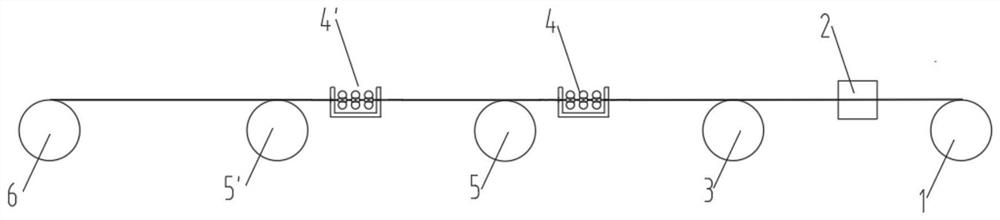

Electrochemical drawing process and electrochemical drawing device for metal wire material

ActiveCN104722590AReduce surface hardnessReduce the number of annealingElectrolytic agentMetal filament

The invention discloses an electrochemical drawing device for a metal wire material. According to the electrochemical drawing device, a direct-current power supply 1 and an electrolytic cell 3 in which an electrolyte 2 is contained are additionally arranged, wherein a positive electrode of the direct-current power supply is connected to the metal wire material 5 through a power connection post 4; a negative electrode of the direct-current power supply is communicated with the electrolyte 2 through a cathode stainless steel sheet 6; insulation blocks 7 are respectively arranged at the two ends of the electrolytic cell 3 and used for insulating and separating a wiredrawing mould 8 from the electrolytic cell 3, and insulating and separating the metal wire material 5 from the electrolytic cell 3. Compared with the conventional drawing, the electrochemical drawing process has the advantages that the surface hardness of the wire material can be reduced, the surface quality is improved, various scratches and cracks on the surface of the material are effectively reduced, the middle annealing times of the wire material are reduced, and the wire material preparation efficiency is improved; under the same process condition, the surface-layer hardness of the aluminum alloy material is reduced by 10%-20%, the drawing force is reduced by 8%-18%, and the drawing force of the copper alloy is reduced by 10%-27%.

Owner:LANZHOU WEITE WELDING MATERIAL FURANCE BURDEN

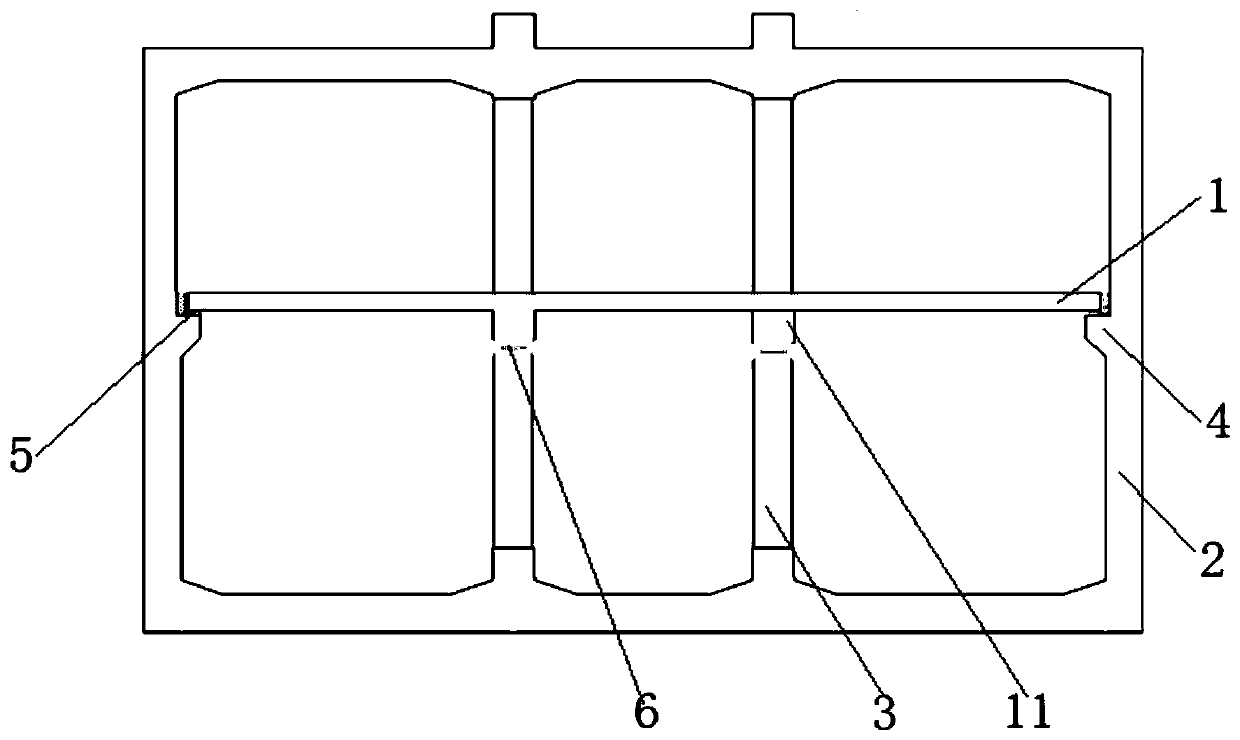

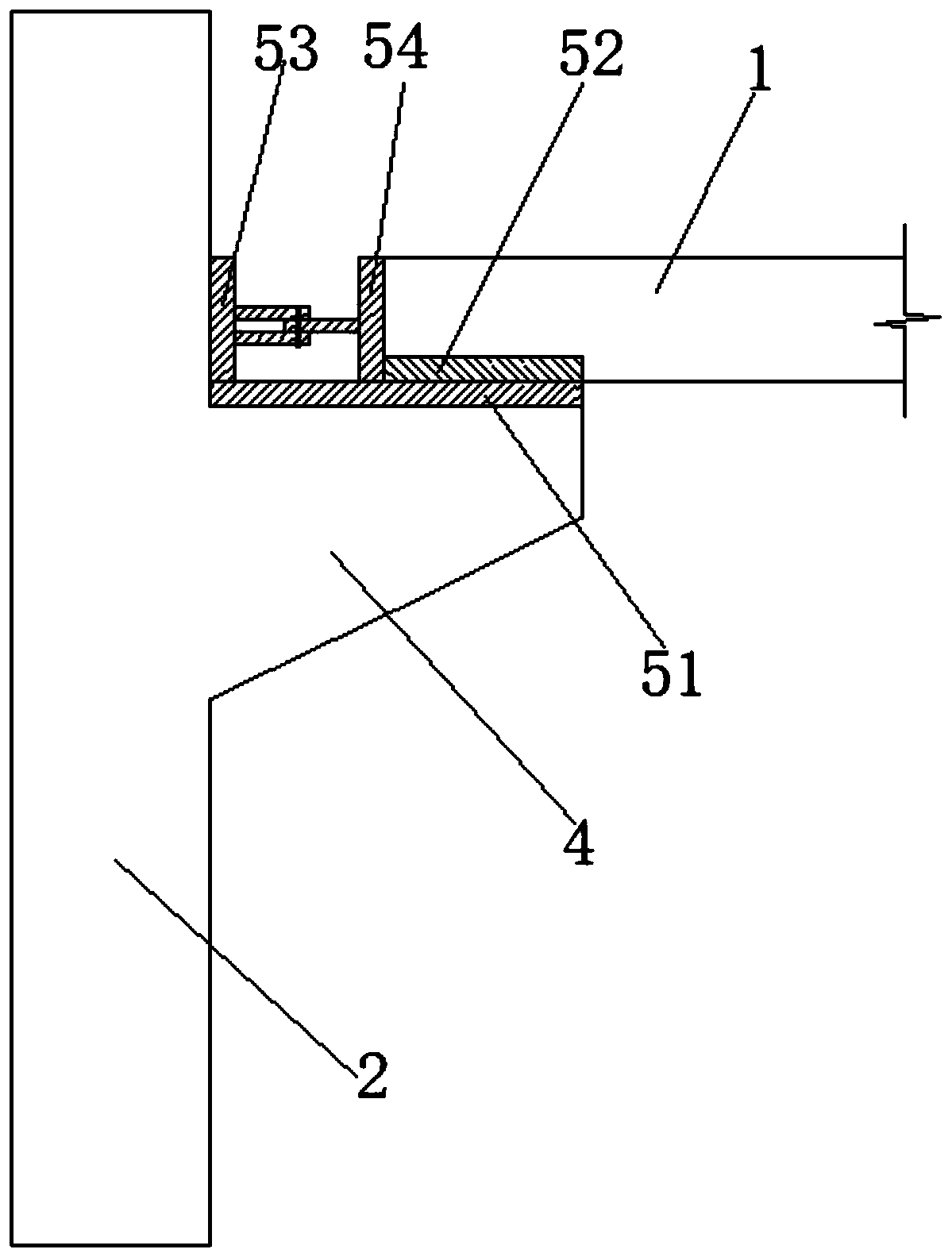

Rapid photocuring 3D printer material box and 3D printer

PendingCN110027209AIncrease return speedReduce pullout forceManufacturing enclosures3D object support structuresEngineeringOxygen

The invention relates to the field of printers, and relates to a rapid photocuring 3D printer material box and 3D printer. The rapid photocuring 3D printer material box comprises a resin groove side wall and a curing inhibitor conveying layer, the bottom of the side wall of the resin tank is connected to the upper surface of the curing inhibitor conveying layer to define a resin tank, the fast photocuring 3D printer material box is provided with a curing inhibitor supply part which is used for providing a curing inhibitor to the curing inhibitor conveying layer, the curing inhibitor supplyingpart is arranged to provide a curing inhibitor to the curing inhibitor conveying layer well and continuously. The curing inhibitor enters the resin of the resin tank, part of the resin in the resin tank is mixed with oxygen to form an oxygen polymerization phenomenon, solid and liquid separation is carried out on the cured resin and uncured resin, the drawing force is remarkably reduced, the resinreflux speed is accelerated, the printing speed is remarkably improved, the resin reflux speed of the 3D printer is high, and the printing speed is remarkably improved.

Owner:SHINING 3D TECH CO LTD

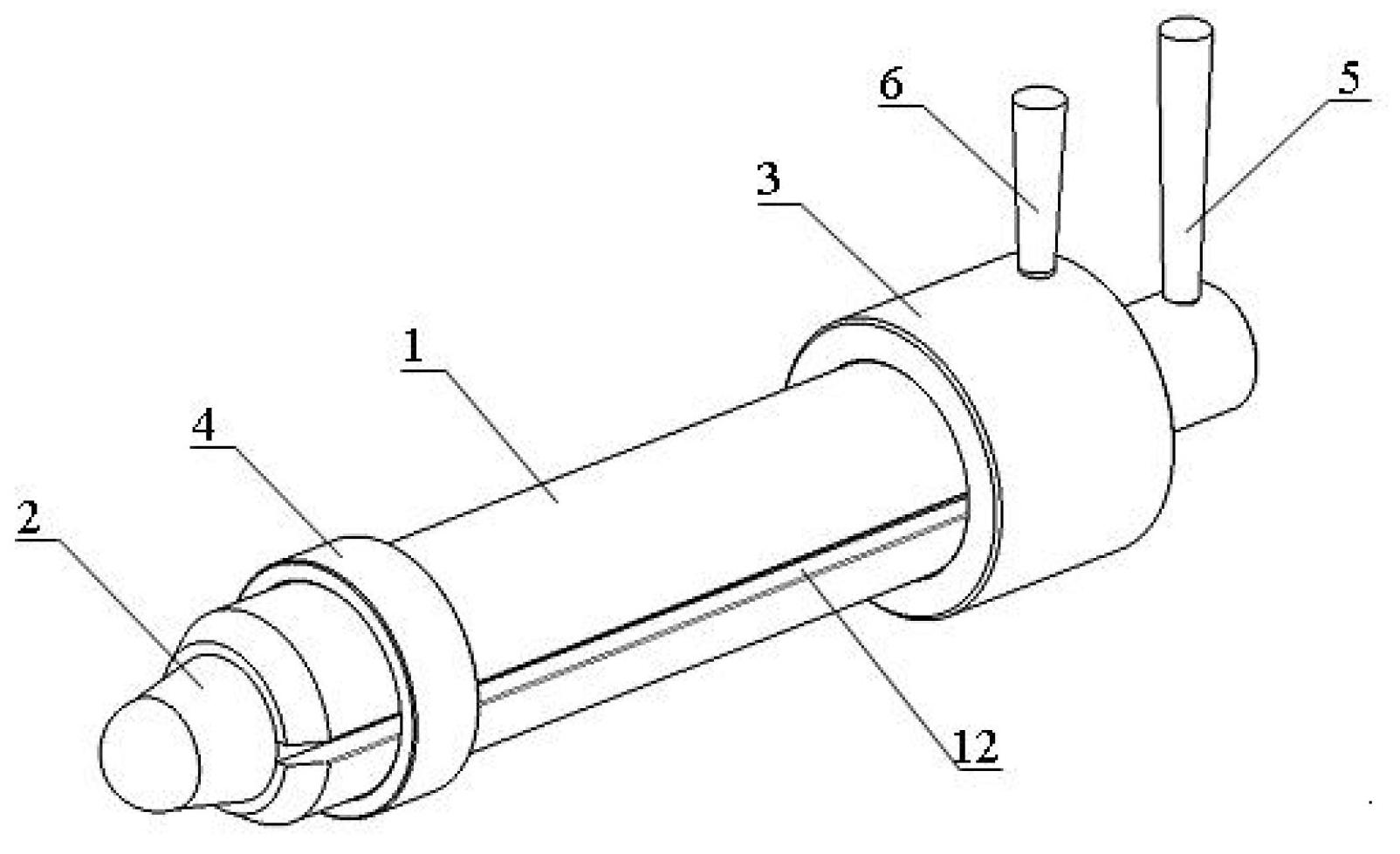

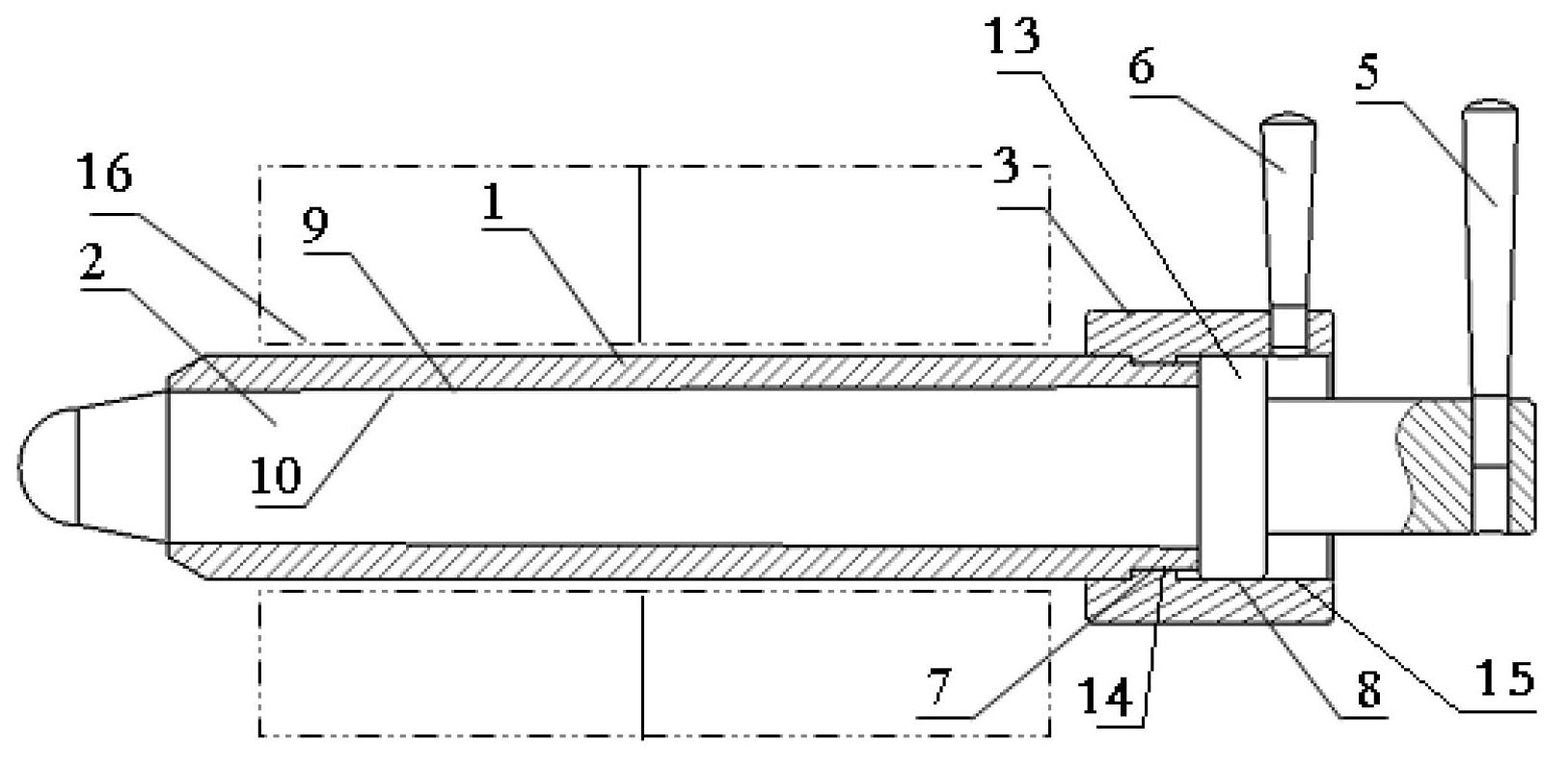

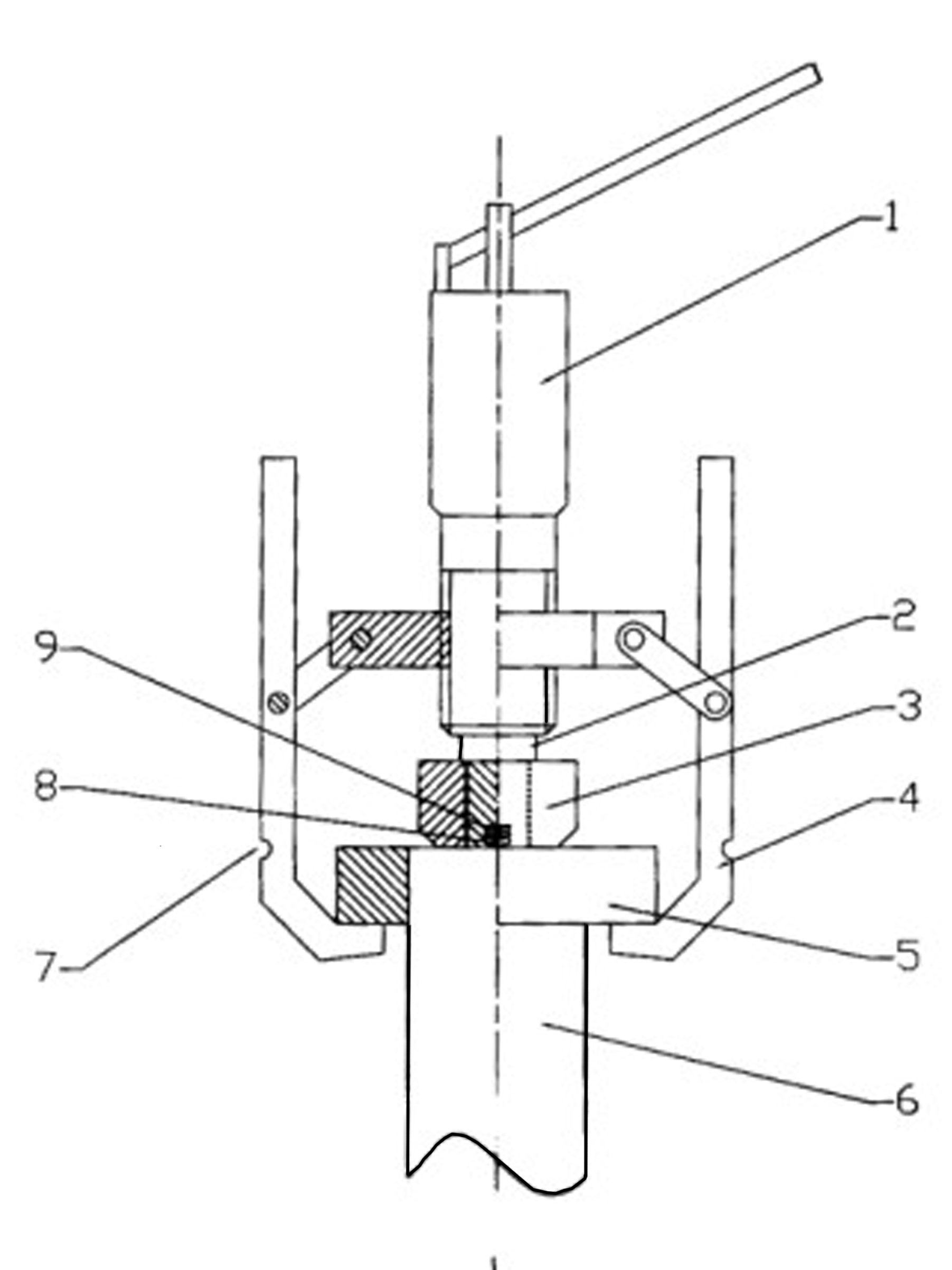

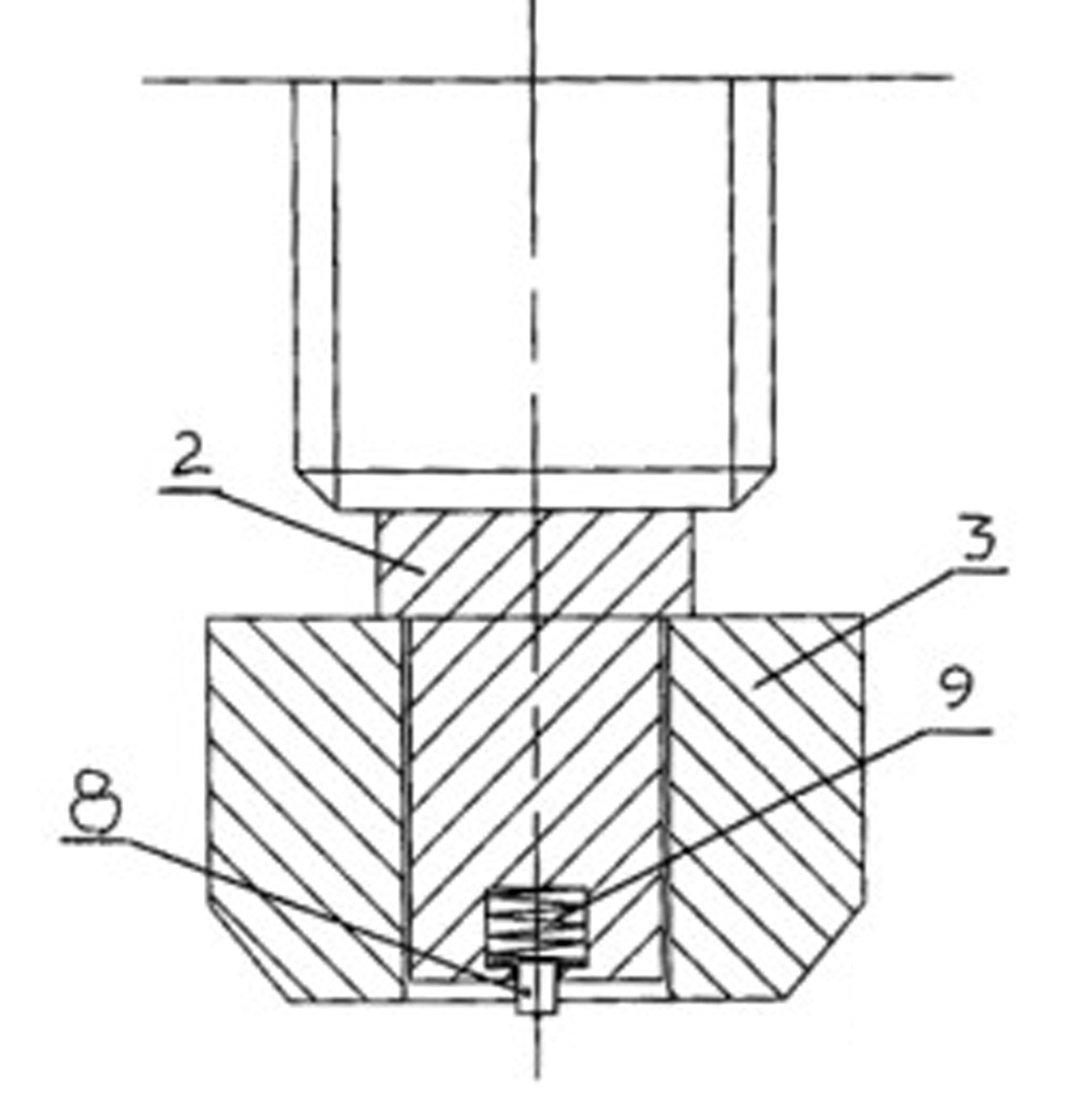

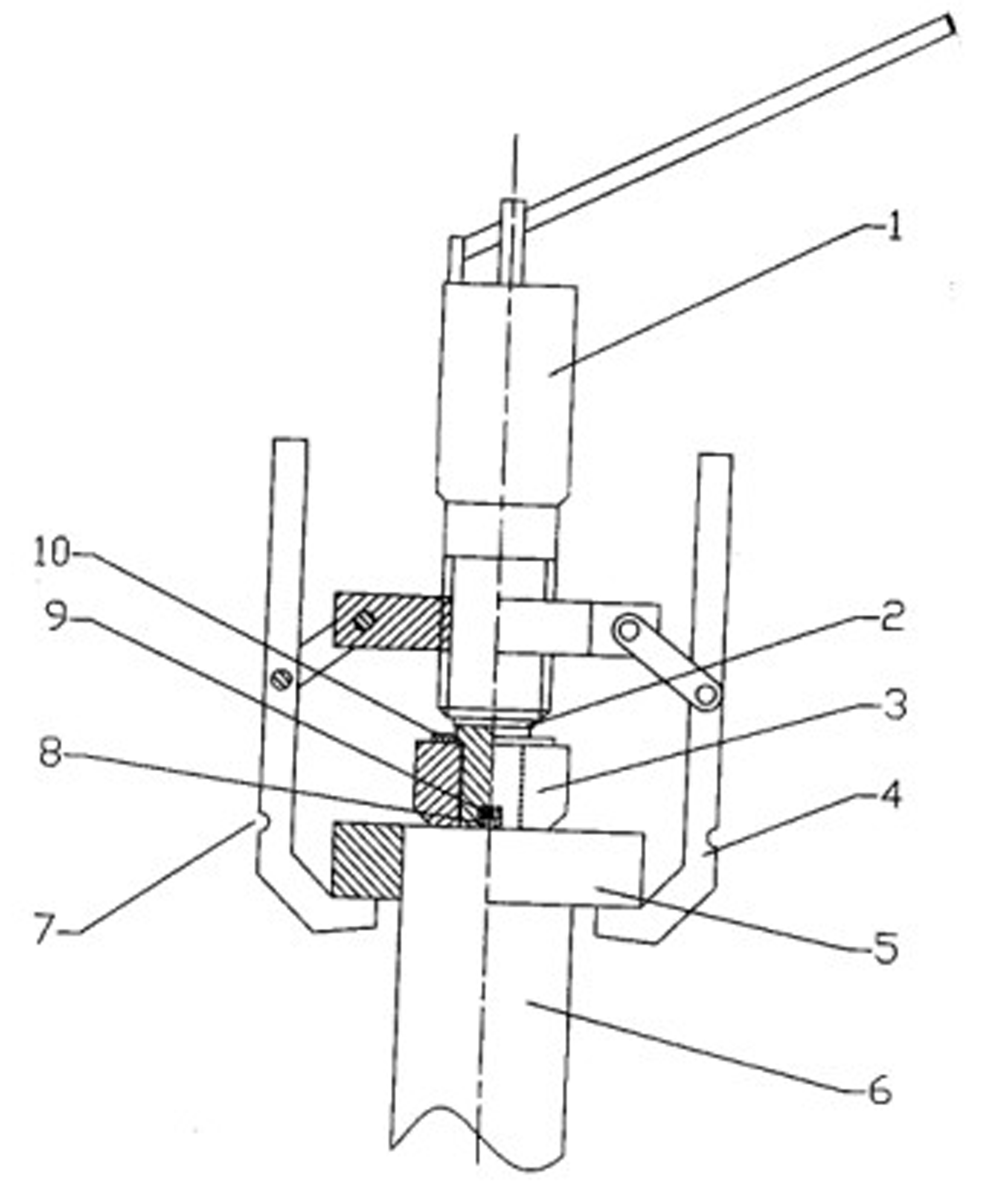

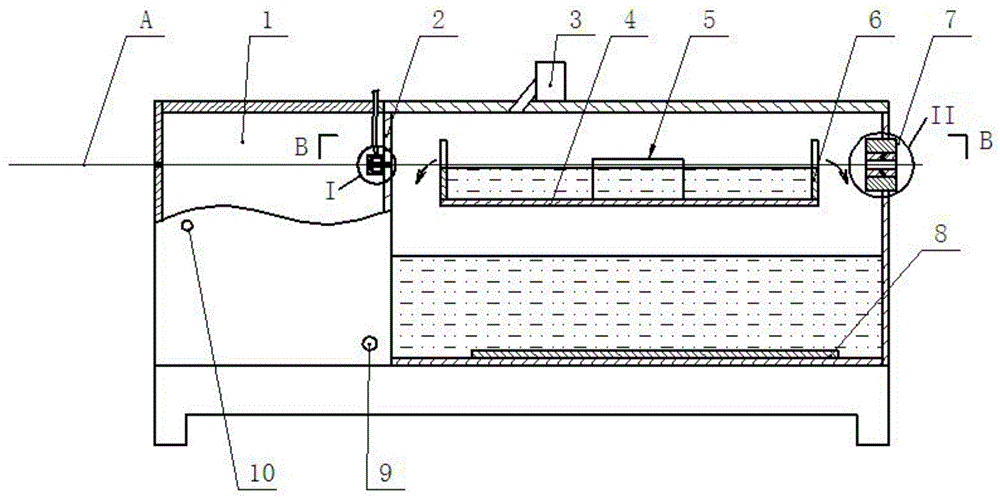

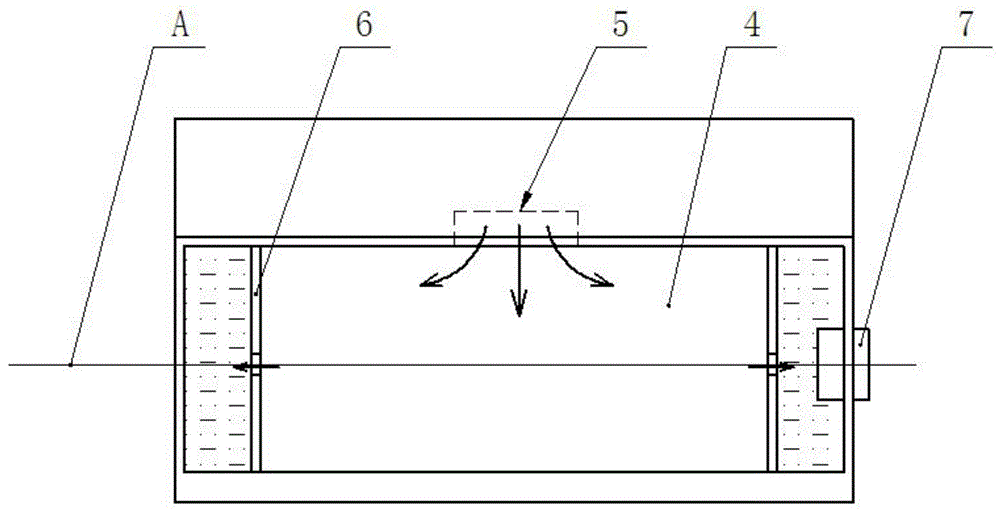

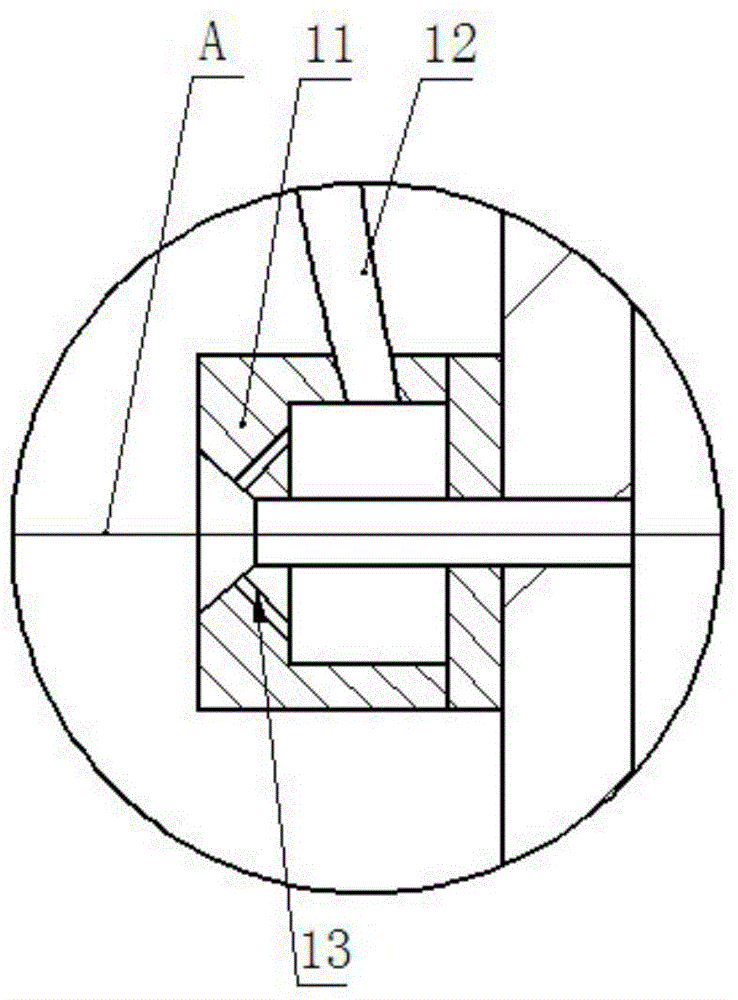

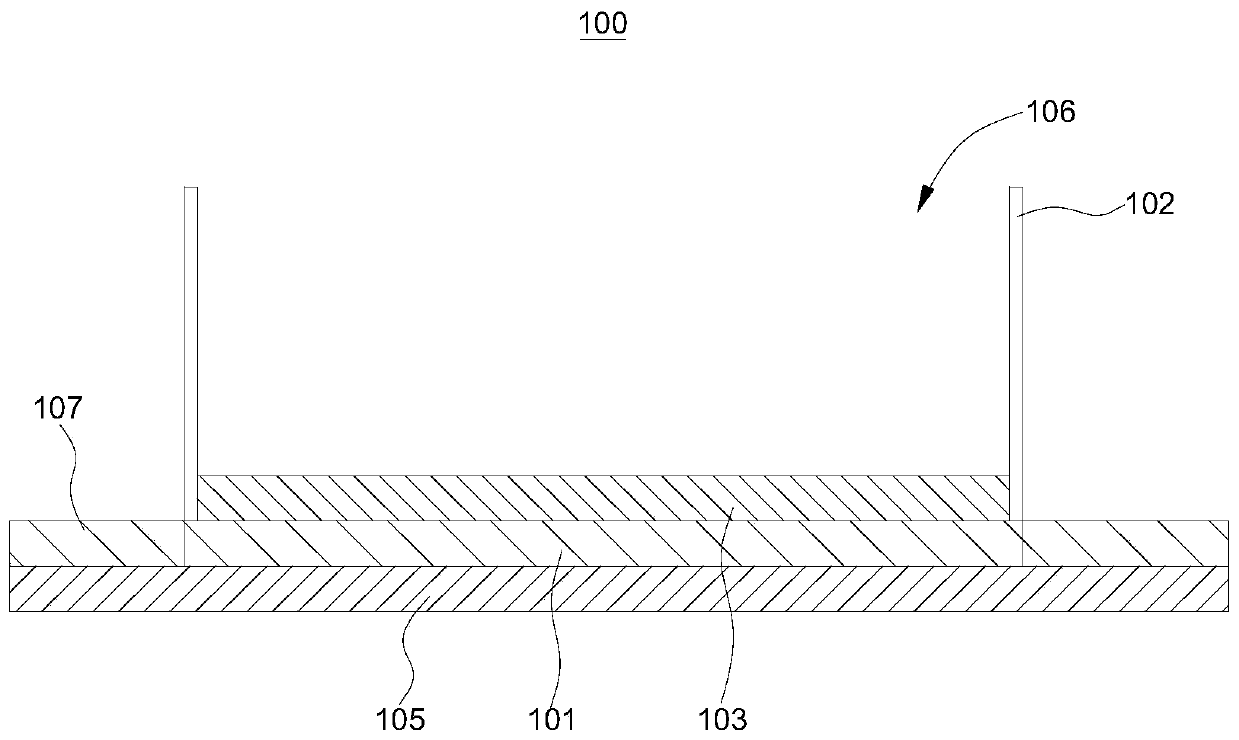

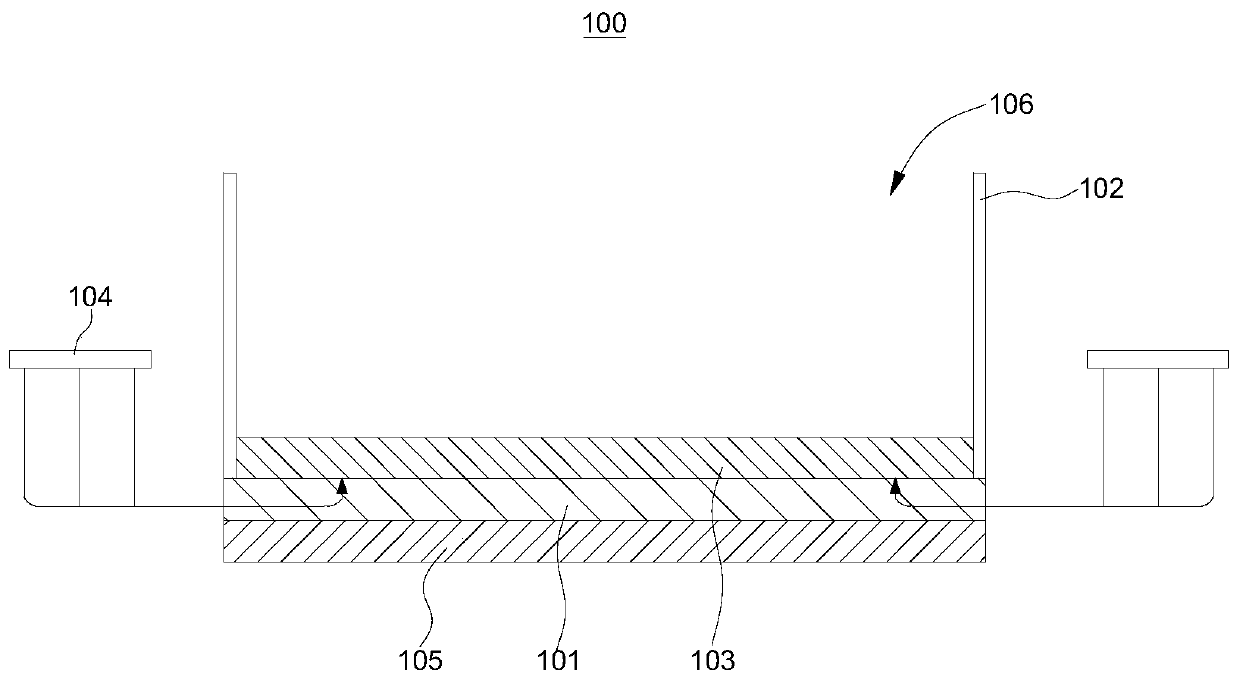

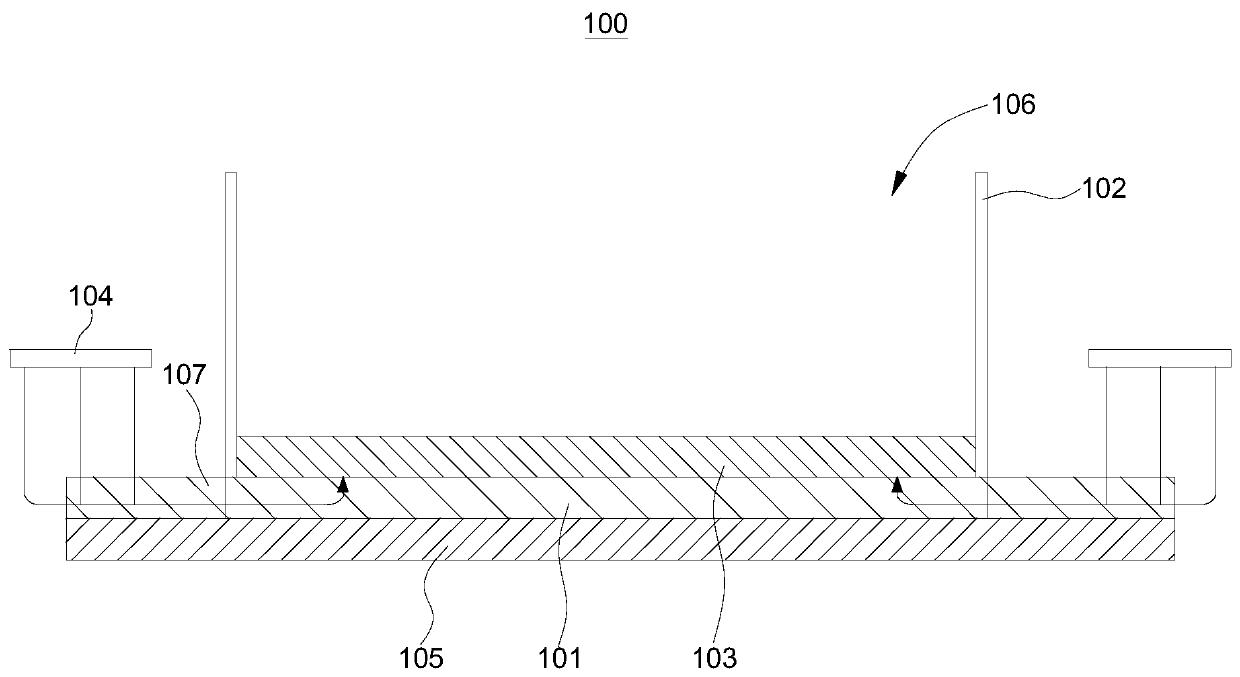

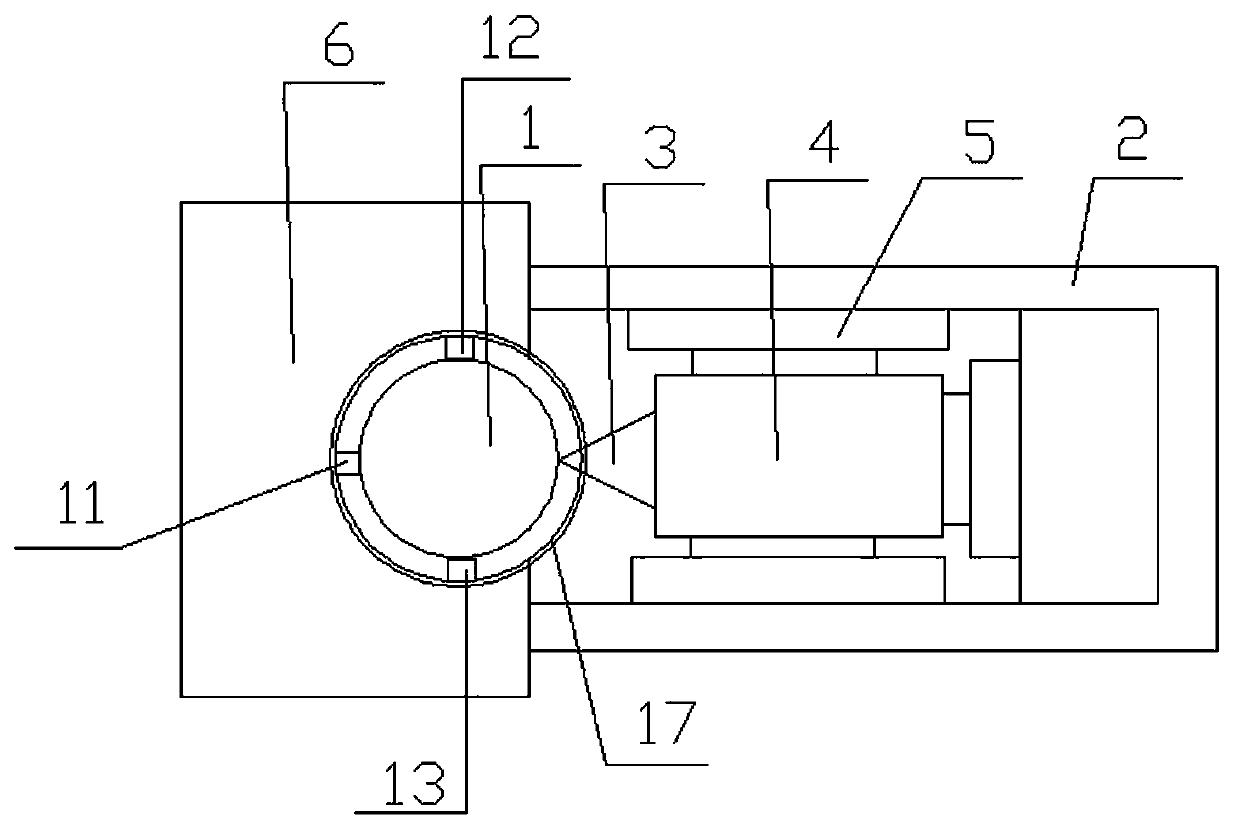

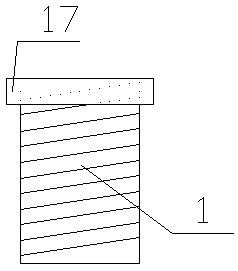

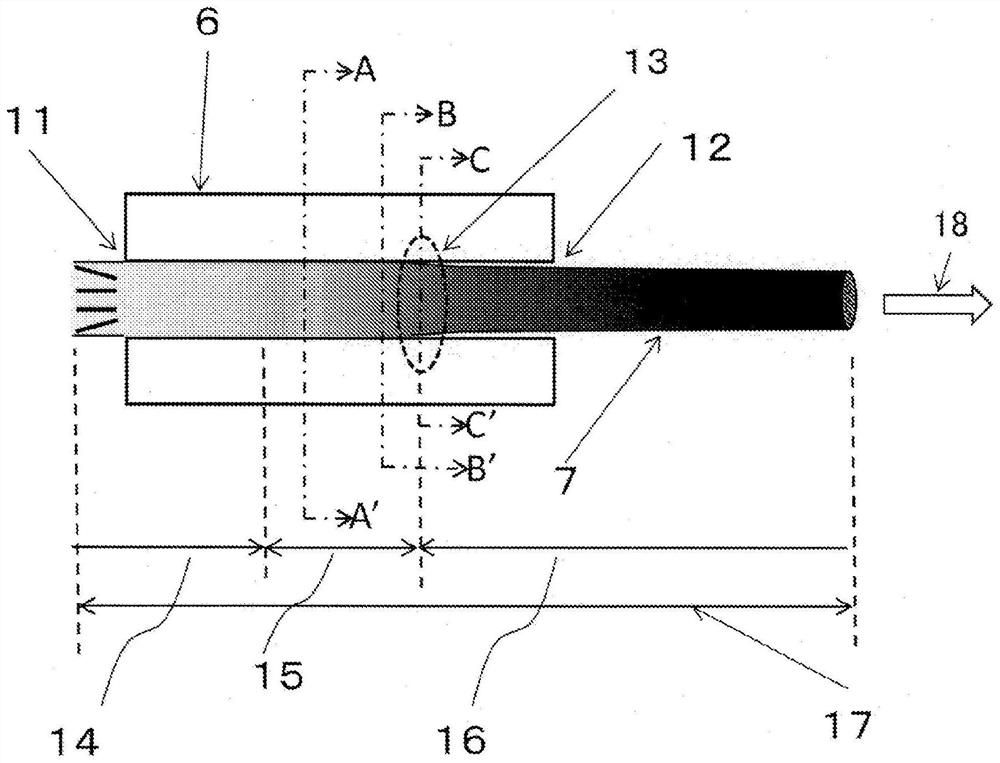

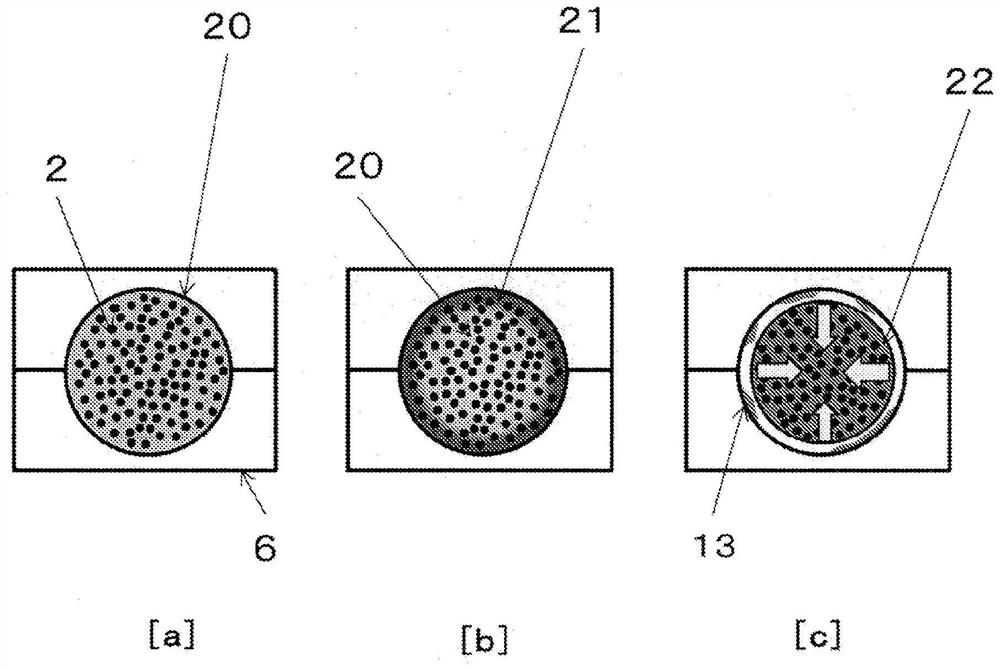

Induction heating auxiliary drawing device for preparing capillary tube

PendingCN113083922ARaise the deformation temperatureImprove plasticityDrawing diesCapillary TubingEngineering

The invention discloses an induction heating auxiliary drawing device for preparing a capillary tube. The induction heating auxiliary drawing device comprises an induction heating device, a drawing mold, a vibration generator and a cooler. The drawing mold is provided with a shaft hole for the capillary tube to pass through before drawing. The induction heating device is arranged on one side of the shaft hole, and the vibration generator is installed on the outer surface of the drawing mold. The cooler is arranged on the other side of the shaft hole relative to the induction heating device, and the induction heating device, the drawing mold and the cooler are coaxially and oppositely arranged. The deformation temperature of the tube is increased through the induction heating device, and the plasticity of the tube is improved, so that the pass deformation is finally increased and the drawing pass is reduced; meanwhile, an ultrasonic vibration device enables the mold to vibrate, improves the friction condition and reduces the drawing force, finally, the pass deformation can be increased, the drawing pass can be reduced, and large-deformation drawing of the capillary tube is achieved through the multi-energy-field combined auxiliary drawing device.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Foundation bolt deburring device

ActiveCN110883206AAvoid crackingPrevent flowPinsMetal-working feeding devicesArchitectural engineeringElectric machinery

The invention discloses a foundation bolt deburring device. The foundation bolt deburring device comprises a mounting frame, a jacking head, a driving mechanism used for driving the jacking head to move left and right and a bolt automatic clamping mechanism, wherein the driving mechanism is fixedly connected with the mounting frame, and the fixed end of the jacking head is fixedly connected with the power output end of the driving mechanism. The automatic bolt clamping mechanism comprises a shell, a plurality of clamping rods, a driving motor and a transmission mechanism, wherein the driving motor is used for driving the clamping rods to stretch and contract in the radial direction; the plurality of clamping rods are circumferentially arranged, and the driving motor drives the clamping rods to stretch and contract in the radial direction through the transmission mechanism; and the transmission mechanism and the driving motor are arranged inside the shell, and the shell is fixedly connected with the mounting frame. According to the foundation bolt deburring device, foundation bolts can be automatically clamped, the foundation bolts matched with nuts can be thoroughly deburred, and the situation that the nuts are stolen due to the fact that the foundation bolts are not deburred or are not thoroughly deburred is prevented, so that the safety of an iron tower is guaranteed.

Owner:HENAN POWER TRANSMISSION & TRANSFORMATION CONSTR CO LTD +1

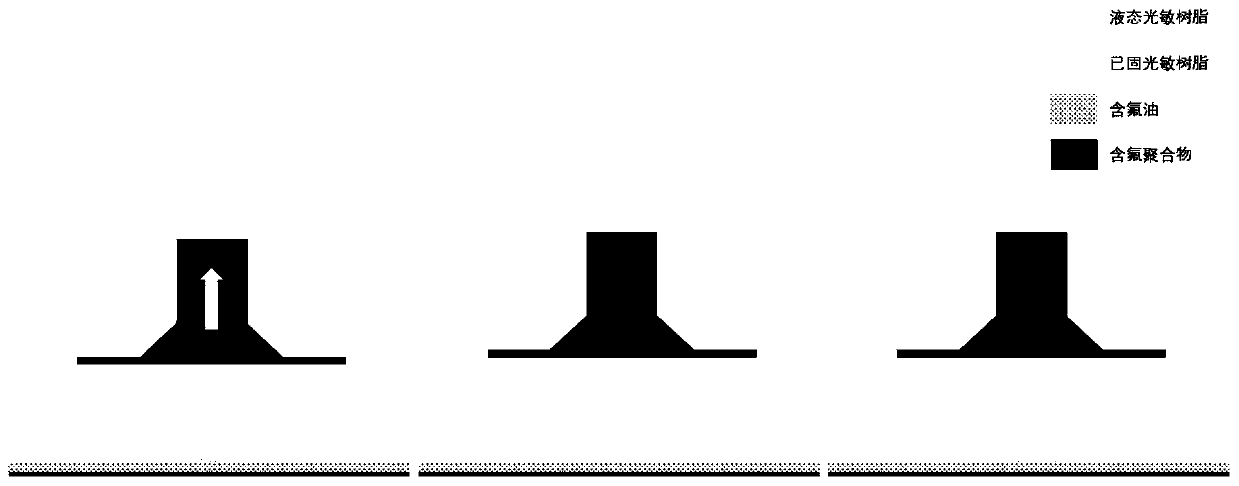

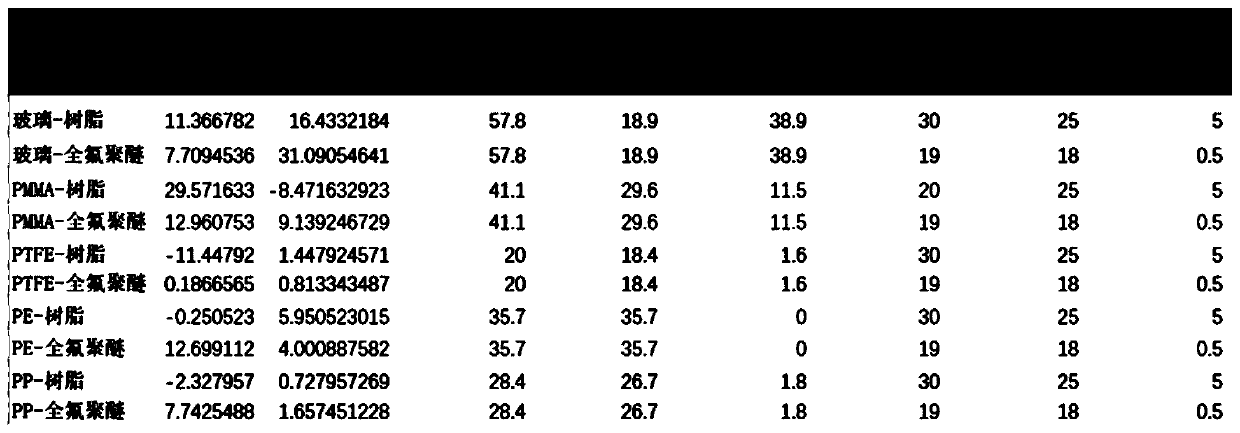

Photocuring three-dimensional printing material box and preparation method thereof, photocuring three-dimensional printing device and photocuring three-dimensional printing method

PendingCN111204041AReduce pullout forceIncrease printing speedManufacturing enclosures3D object support structuresPolymer chemistryOil film

The invention relates to a photocuring three-dimensional printing material box and a preparation method thereof, a photocuring three-dimensional printing device and a photocuring three-dimensional printing method, and belongs to the technical field of three-dimensional printing. The photocuring three-dimensional printing material box comprises a box body, a non-porous fluorine-containing polymer film and a fluorine-containing oil film; the non-porous fluorine-containing film is arranged on at least part of inner surface of a light-transmitting bottom plate; and the fluorine-containing oil filmis adsorbed on the surface, far away from the light-transmitting bottom plate, of the non-porous fluorine-containing polymer film. According to the material box and the preparation method thereof, the device and the method, by utilizing the good surface wettability and chemical affinity between the non-porous fluorine-containing polymer film and the fluorine-containing oil, fluorine-containing oil can be bound, and the non-porous fluorine-containing polymer film and the fluorine-containing oil can be tightly connected; the photocuring printing process is changed from solid-solid separating into solid-liquid separating so that drawing force in the release process can be effectively reduced, and the printing speed and the printing area are increased; and a printing interface is in a liquidstate, so that high-speed printing is achieved, and meanwhile, heat can be dissipated in time so as to ensure the stability of material.

Owner:SHINING 3D TECH CO LTD

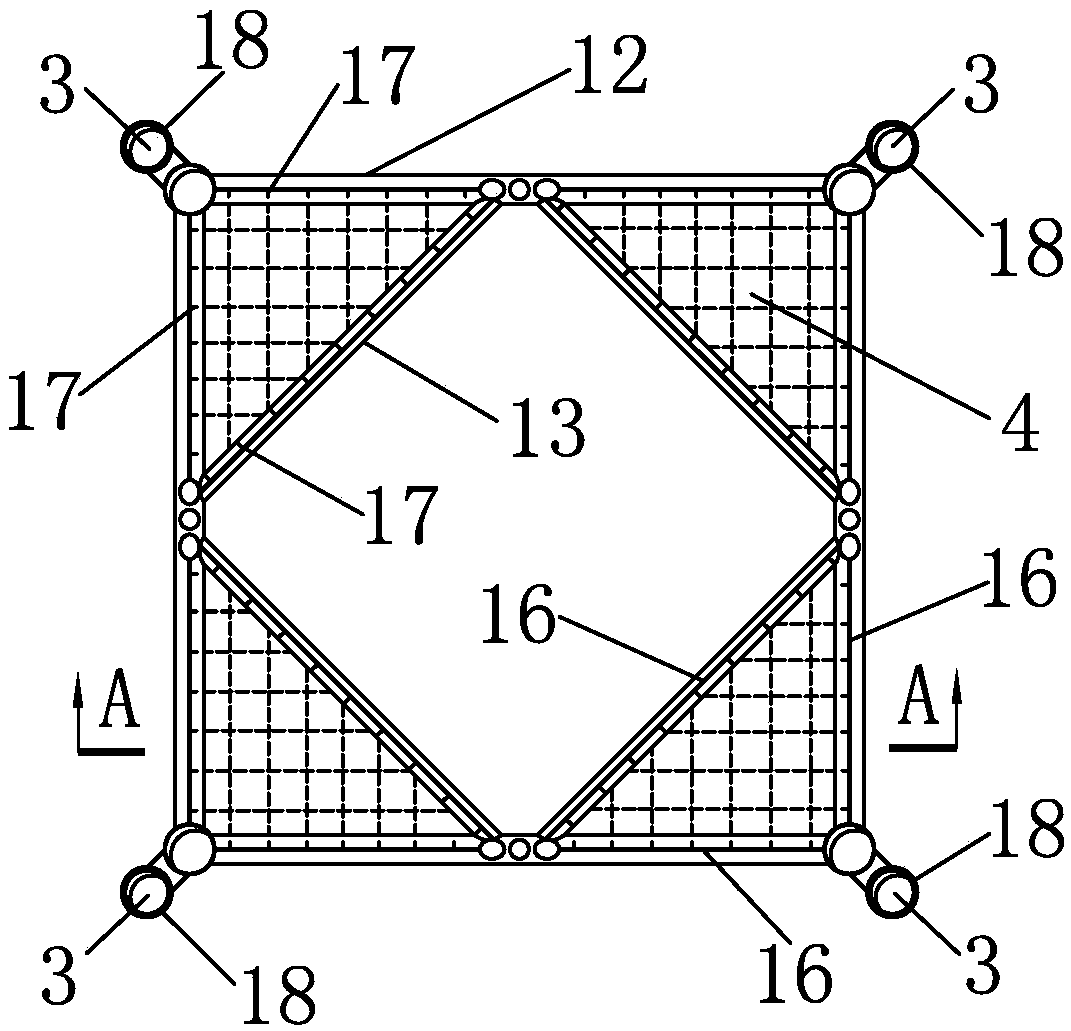

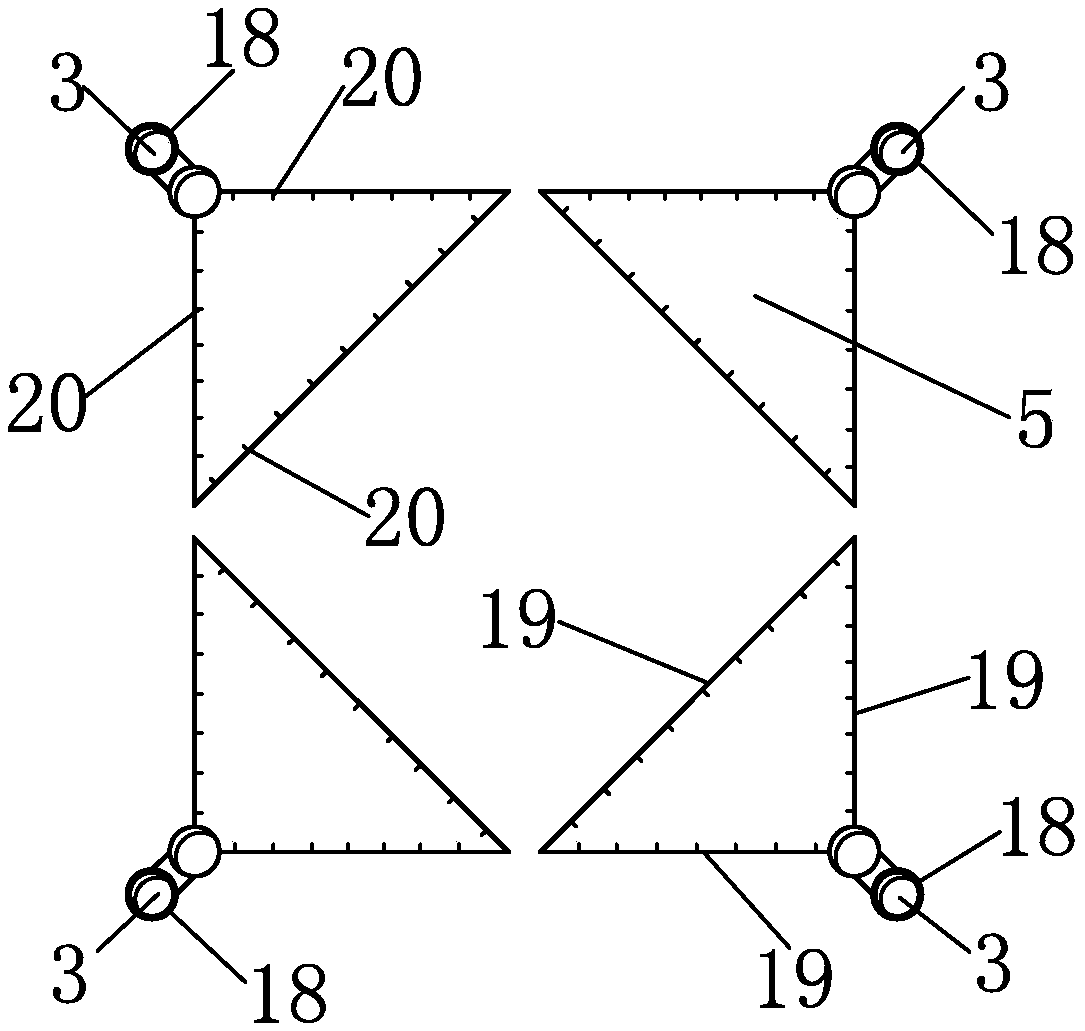

Shock insulation structure for separating upper story and lower story in two-story station

ActiveCN111305263AAvoid damagePrevent excessive slippageArtificial islandsProtective foundationArchitectural engineeringStringer

The invention provides a shock insulation structure for separating the upper story and the lower story in a two-story station. The shock insulation structure comprises a middle plate, side walls and amiddle column. The side walls are connected with the middle plate through ox horn legs. Friction sliding supports are arranged between the middle plate and the ox horn legs. A longitudinal beam of the middle plate is connected with the top end of the middle column through a lead core shock insulation support. According to the shock insulation structure for separating the upper story and the lowerstory in the two-story station, the damage degree of a two-story subway underground station structure in a strong earthquake can be greatly reduced, and therefore the overall anti-seismic property ofthe two-story subway underground station structure is improved.

Owner:NANJING UNIV OF TECH +1

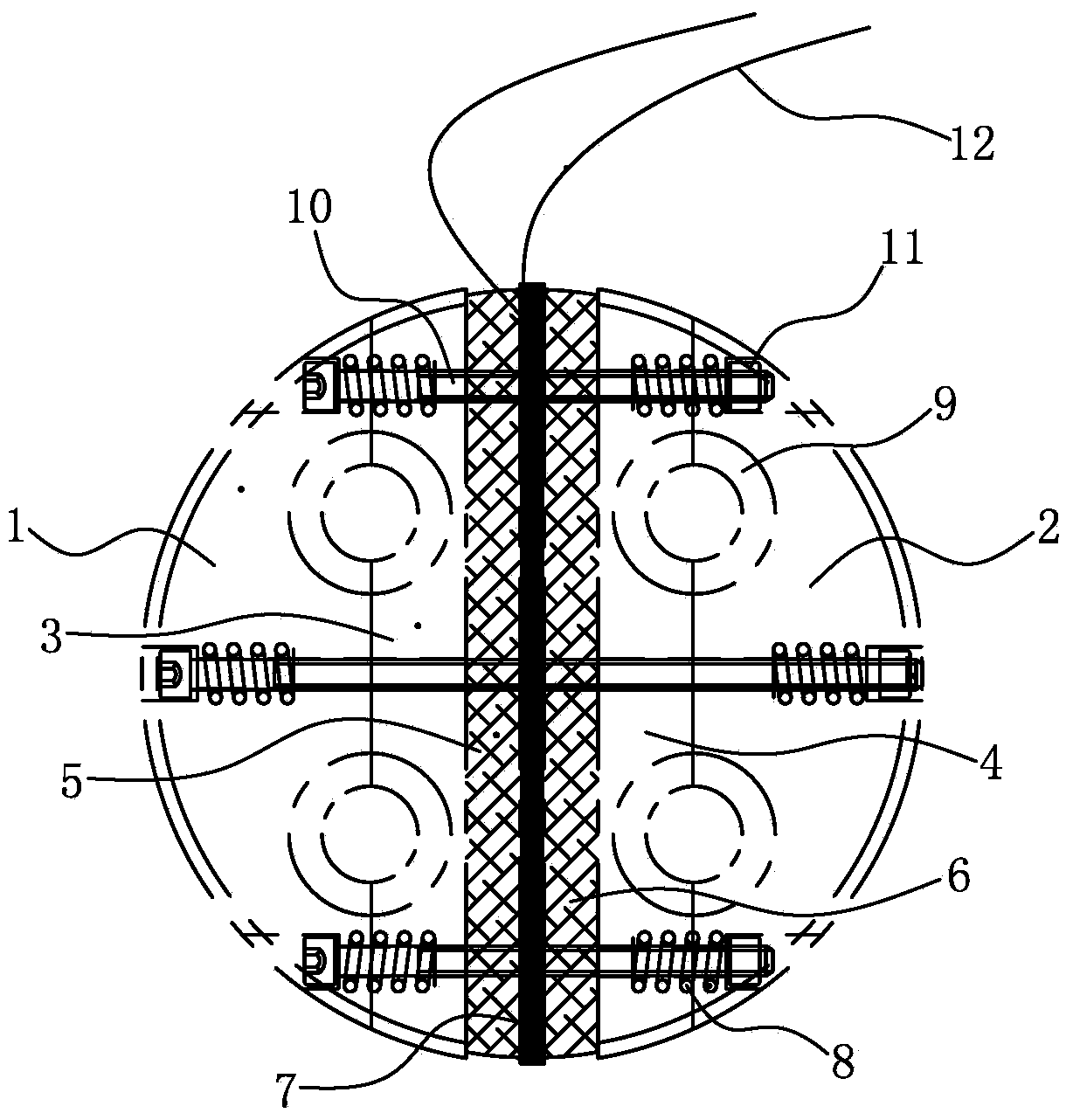

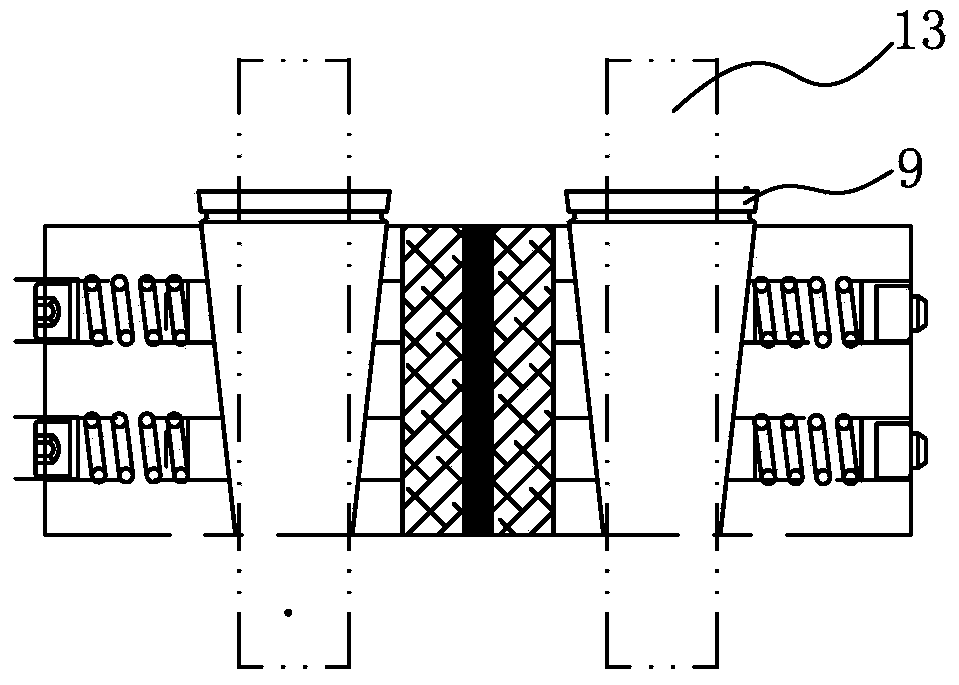

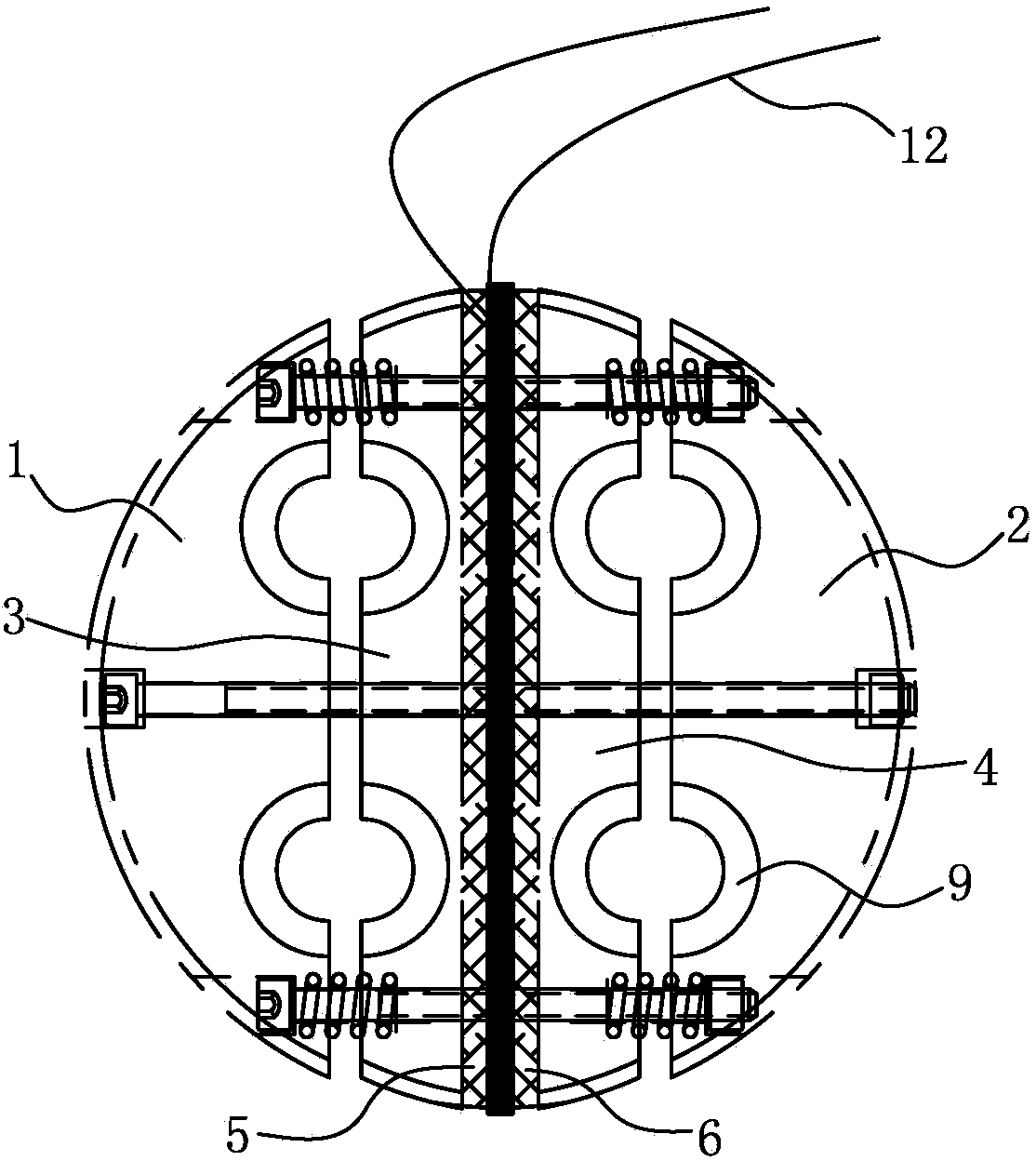

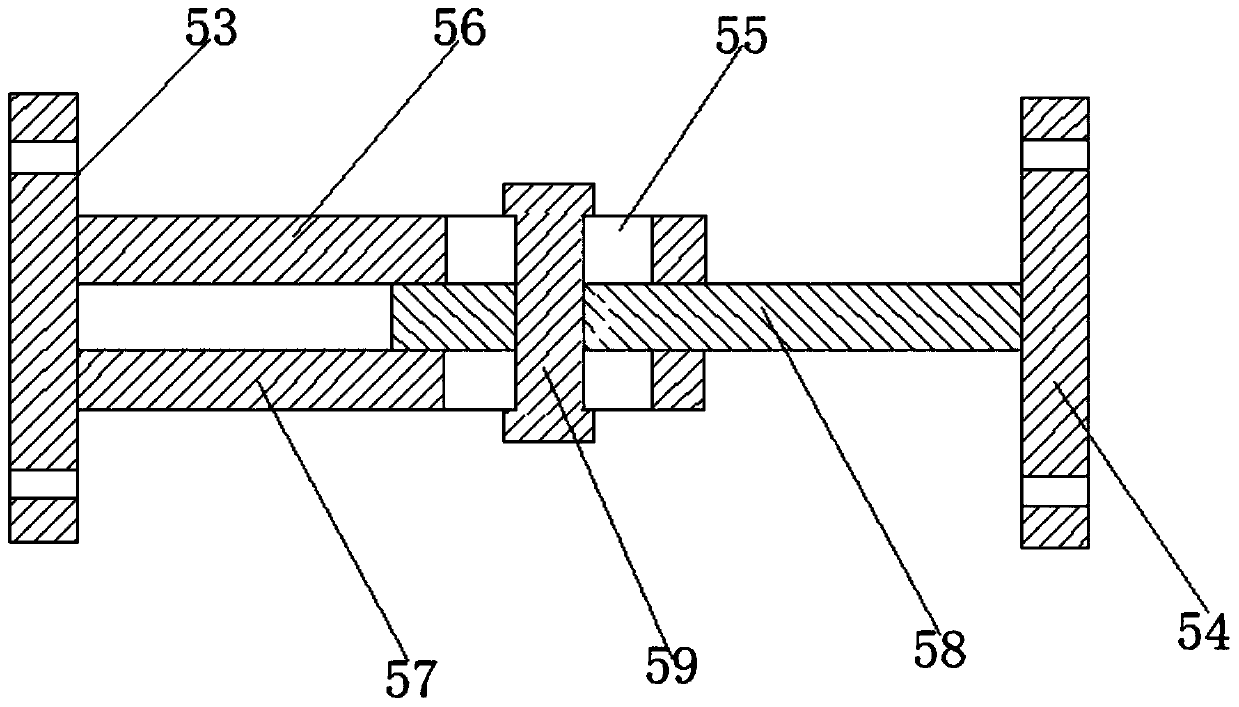

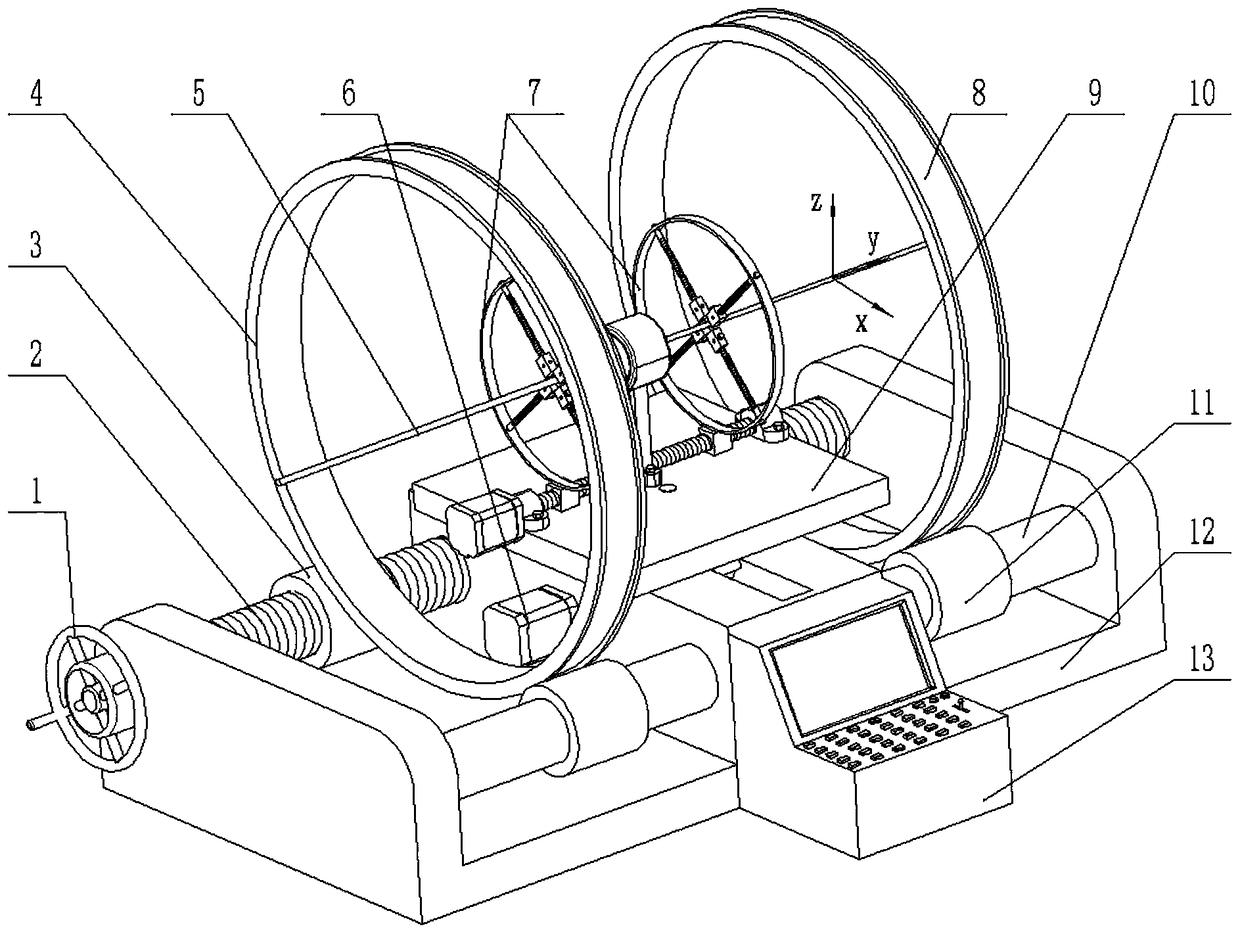

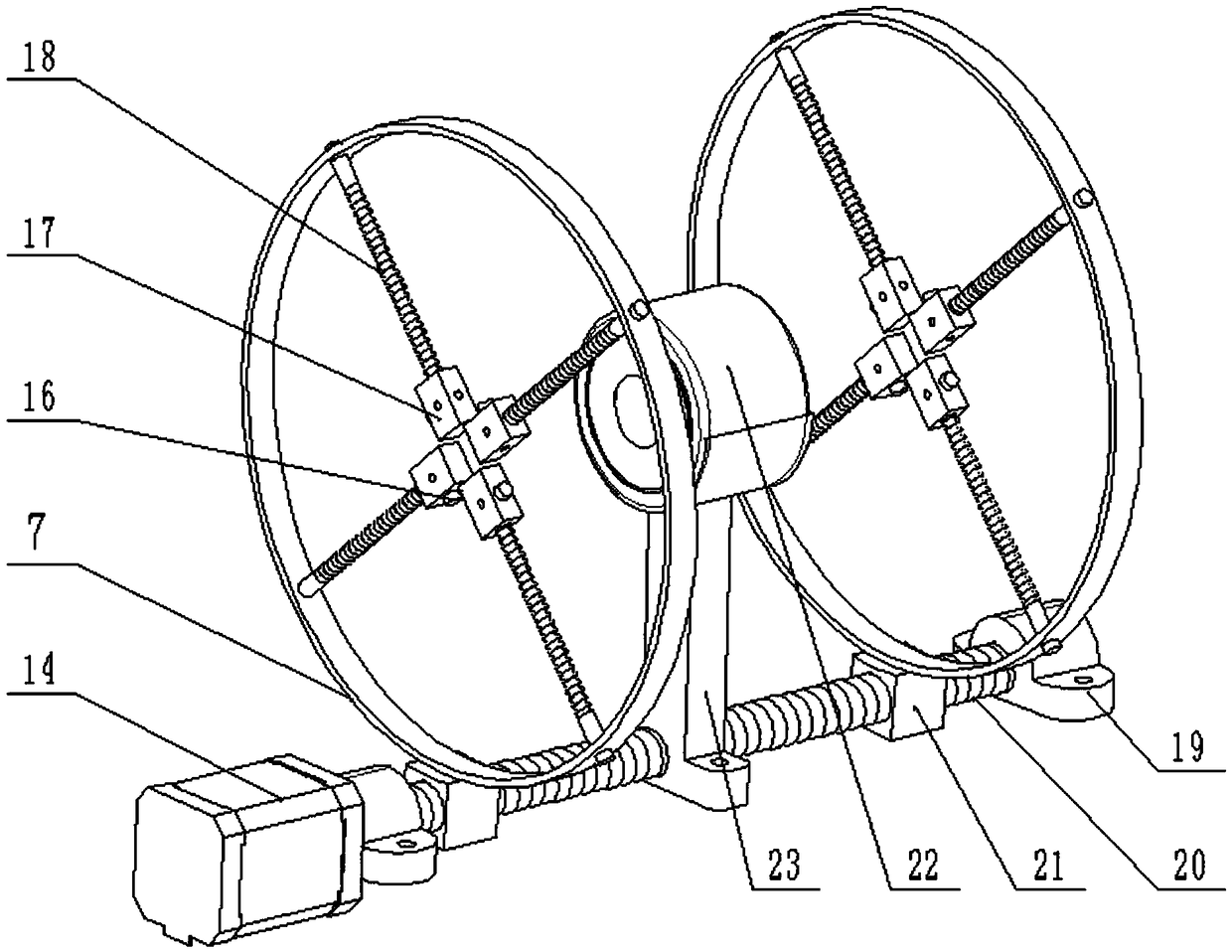

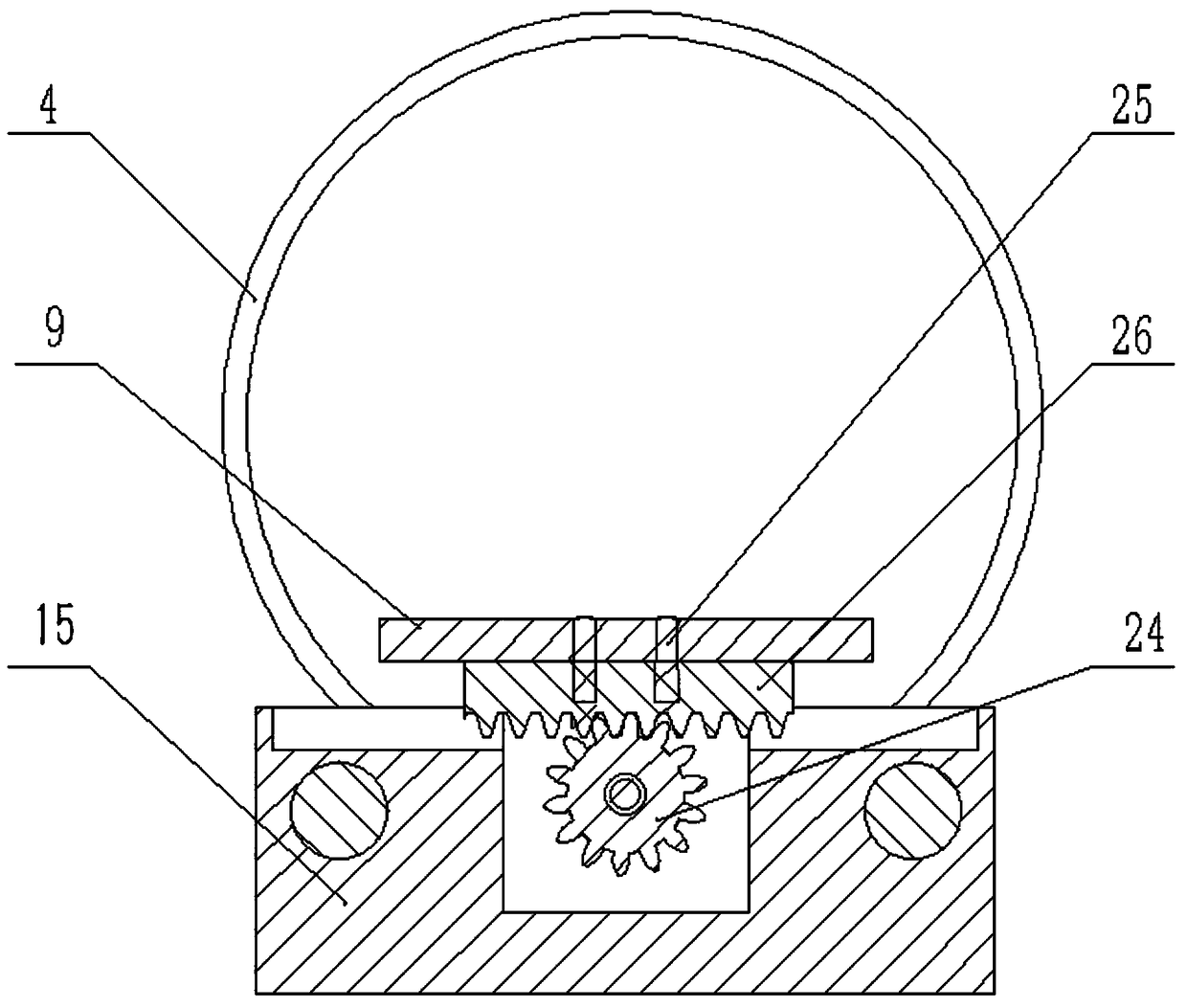

Auxiliary magnetic field device for magneto plastic wire drawing and using method thereof

ActiveCN109500111AReduce pullout forceUniform magnetic fieldMetal working apparatusMagnetoGenerating unit

The invention discloses an auxiliary magnetic field device for magneto plastic wire drawing. The auxiliary magnetic field device comprises a machine frame, wherein a protruding part is arranged in themiddle of the machine frame, a first screw rod and a sliding rod which are parallel to each other and penetrate the protruding part are arranged in the machine frame, the first screw rod can rotate,a hand wheel is fixedly arranged at one end of the first screw rod, the thread directions of the portions, on the two sides of the protruding part, of the first screw rod are opposite, and each of thetwo sides of the protruding part is provided with a magnetic field generating unit; a first motor is fixedly arranged on the protruding part, a supporting plate is arranged on the top of the first motor in a sliding mode, and the supporting plate can move; a magnetic field detection part and a wire drawing die are arranged above the supporting plate, and a power supply control and signal acquisition platform is arranged on the machine frame. The auxiliary magnetic field device for magneto plastic wire drawing and the using method of the auxiliary magnetic field device can accurately measure the magnetic field around wire drawing material, so that a uniform magnetic field can be obtained through continuous adjusting to guarantee for the magneto plastic wire drawing.

Owner:TAICANG FANSHENG ELECTRONICS TECH CO LTD

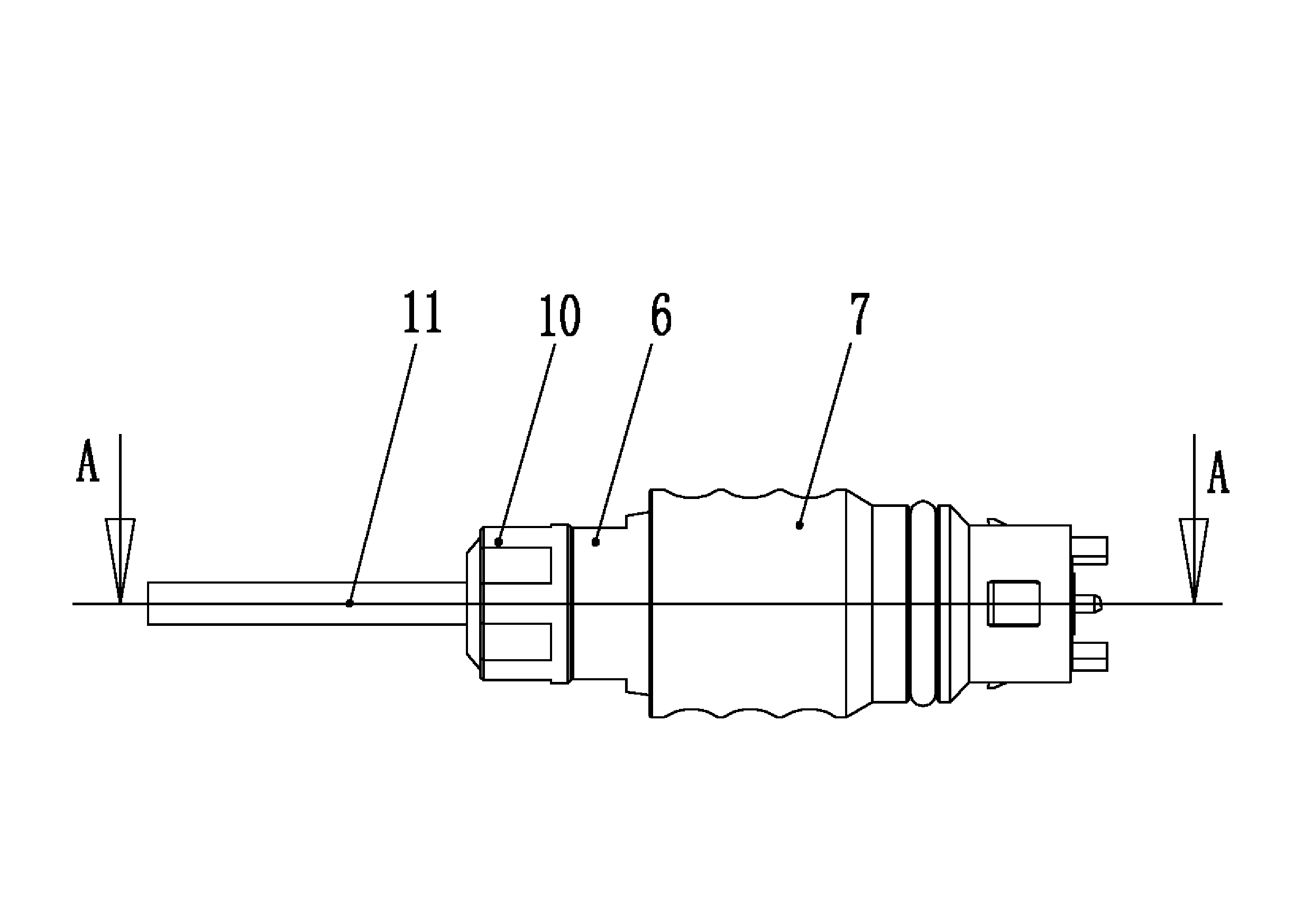

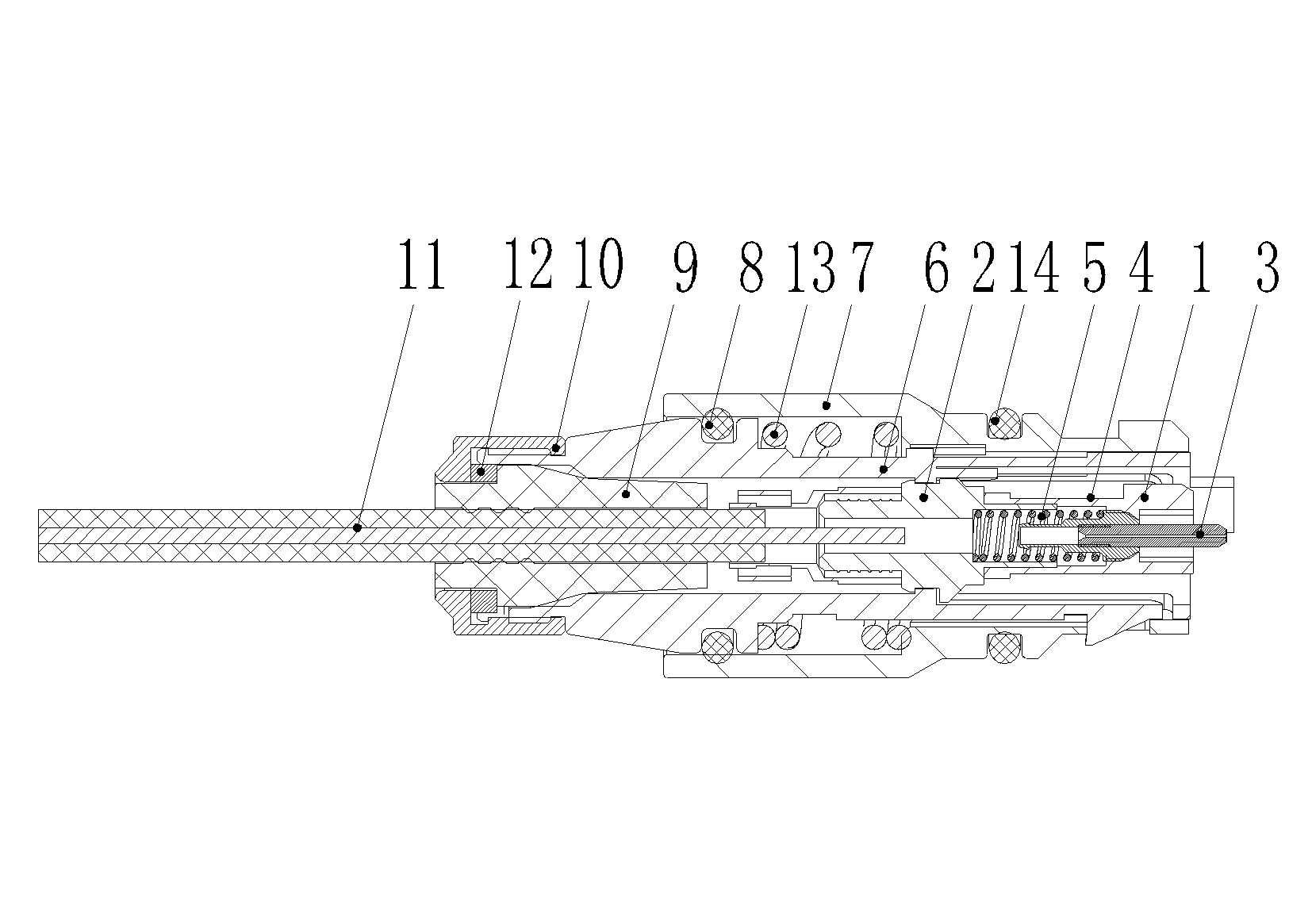

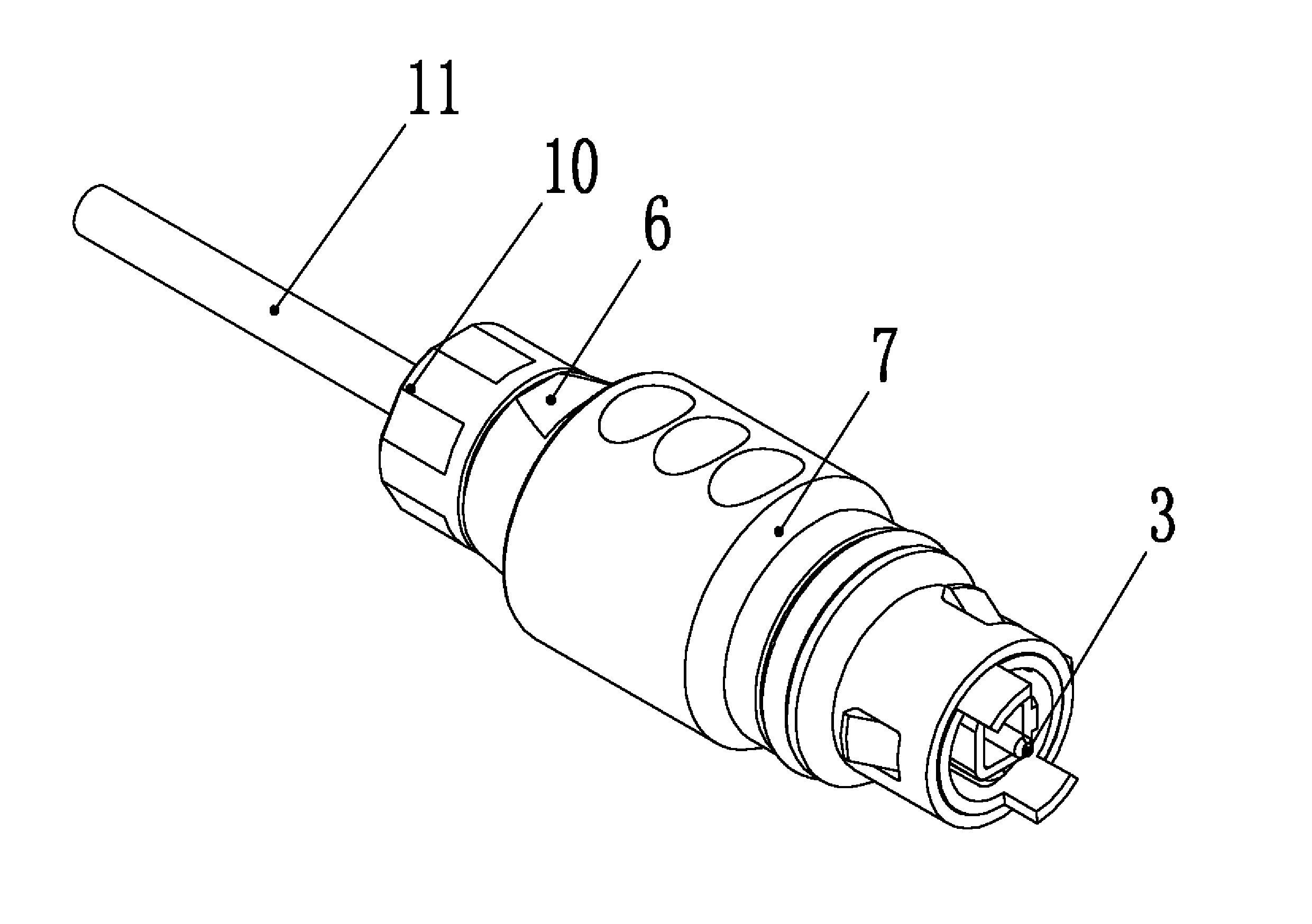

Small-pullout-force optical fiber connector shell and optical fiber connector using same

InactiveCN102385119AReduce pullout forcePull out solutionCoupling light guidesOptical fiber connectorEngineering

The invention relates to a small-pullout-force optical fiber connector shell and an optical fiber connector using the same. The optical fiber connector shell comprises an outer shell and an inner shell, wherein, the outer shell is provided with a mounting hole for assembling the inner shell, the mounting hole comprises a front-end small-diameter section and a rear-end large-diameter section, and a step surface is formed between the large-diameter section and the small-diameter section; the front end of the inner shell is equipped with an elastic agnail which can contract in a radial direction, and the inner shell axially penetrates into the outer shell from the rear end of the outer shell and then is axially matched with a shell hanging hole arranged on the hole wall of the small-diameter section of the mounting hole in an unidirectional limit manner through the elastic agnail; and a return spring is arranged between the step surface and an outer flange which is arranged on the outer wall surface of the inner shell. By adopting the optical fiber connector shell, fractional stepwise separation between the outer shell and the inner shell is realized when the optical fiber connector is separated from a corresponding adapter, which reduces the pullout force needed in the event that the optical fiber connector for pre-connection is separated from the corresponding adapter, and solves the problem of the large pullout force needed in the event that the optical fiber connector is separated from the corresponding adapter.

Owner:CHINA AVIATION OPTICAL-ELECTRICAL TECH CO LTD

Fiber-reinforced molded article and method for producing same

ActiveCN111655766ALittle change in viscosityExcellent curabilityInsulated cablesCoatingsPhthalic acid anhydridePolymer chemistry

Provided is a means by which pultrusion can be continuously performed at high speed and the generation of resin residues that adhere to the inner surface of a mold can be suppressed. The present invention also provides a method for producing a fiber-reinforced molded article, wherein a resin-impregnated fibrous base material obtained by impregnating a reinforcing fiber aggregate of reinforcing fiber bundles with an epoxy resin composition is passed through a pultrusion region and pultruded into a predetermined shape by heat-curing the epoxy resin composition, and the epoxy resin composition contains at least components A to D below. A: An aminophenol-type epoxy resin. B: An acid anhydride having a nadic anhydride structure and an acid anhydride having a hydride structure of a phthalic anhydride. C: At least one filler selected from among a silicon compound, a magnesium compound, a calcium compound, an aluminum compound, and inorganic carbon, and having a Mors hardness of 3 or less. D:A release agent.

Owner:TORAY IND INC

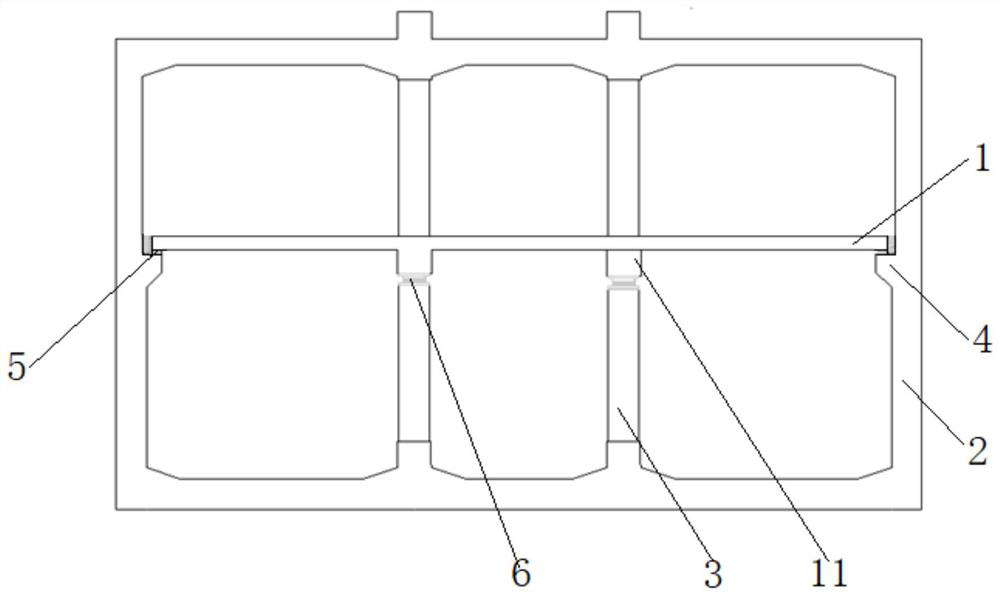

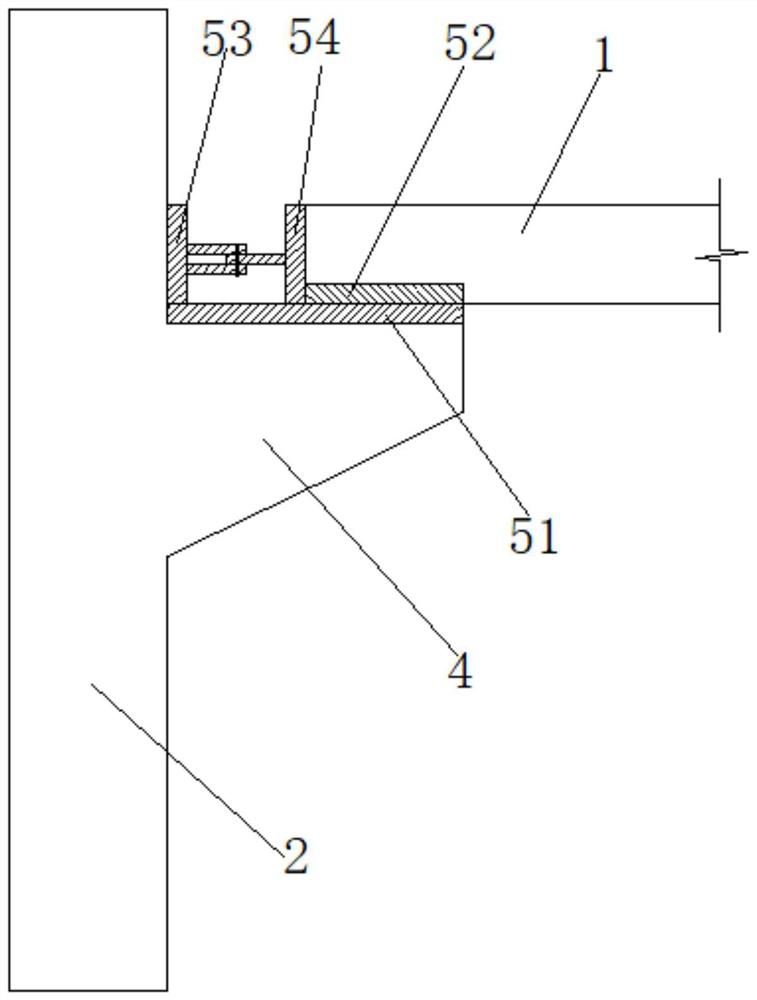

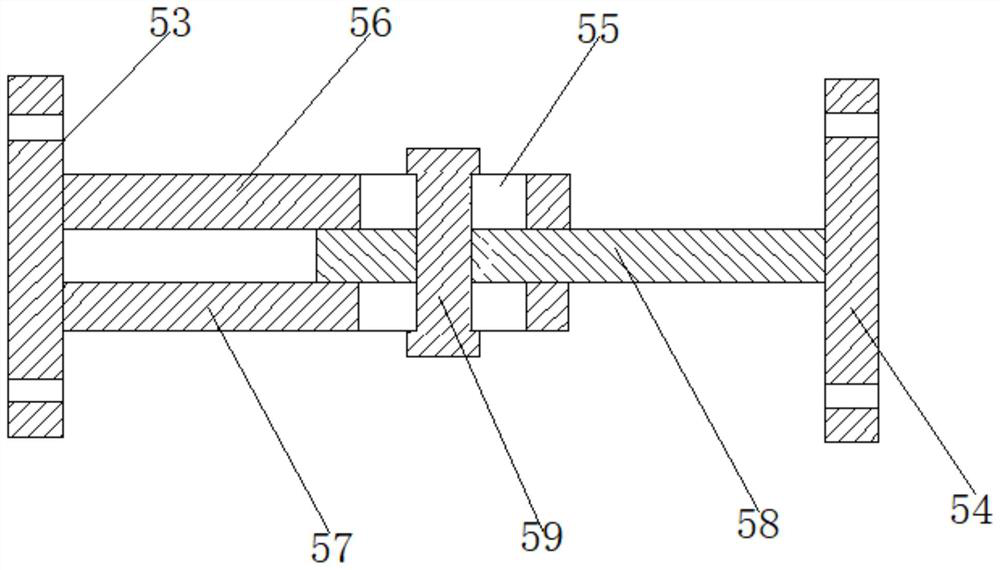

A kind of drawing forming device and method of tin-bismuth alloy welding wire

The invention discloses a drawing forming device and method for a tin-bismuth alloy welding wire. A tin-bismuth alloy blank enters from an inlet of a die base, then penetrates through a drawing die assembled in the die base, and extends from an outlet of the die base, and a drawing machine is used for achieving drawing forming. Drawing liquid heated in a temperature-control mode is contained in the die base, and the liquid level is always higher than the die inlet and the die outlet of the drawing die. The tin-bismuth alloy welding wire difficult to form is drawn to be formed in a large-deformation mode, and the production working procedures are reduced remarkably.

Owner:JIANGXI UNIV OF SCI & TECH

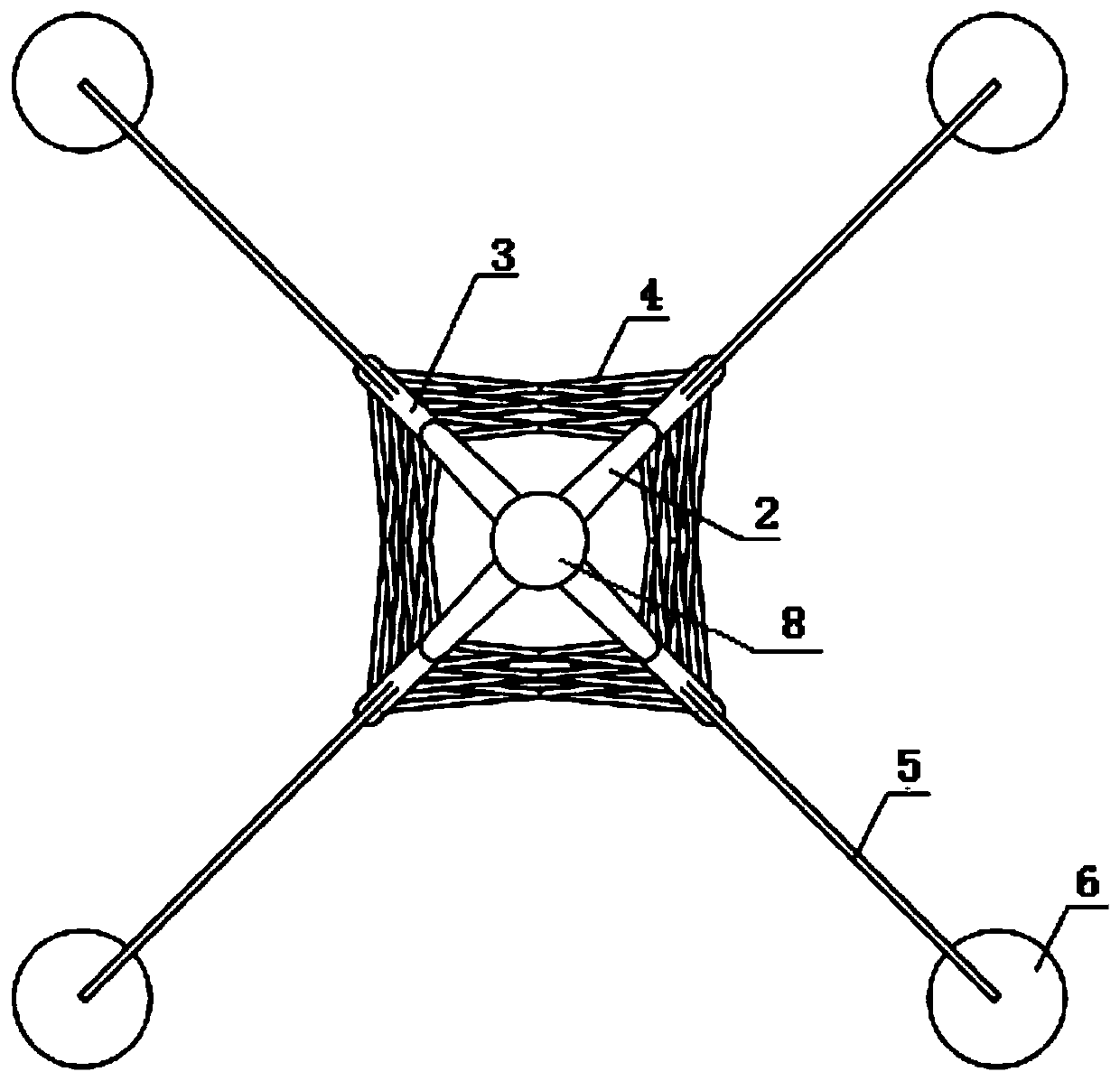

Shallow pile jacket structure for offshore booster station

PendingCN111455959AIncrease weightReduce pullout forceArtificial islandsUnderwater structuresGroutSeabed

The invention provides a shallow pile jacket structure for an offshore booster station. The shallow pile jacket structure for the offshore booster station includes a pedestal foot jacket, non-rock-socketed short piles, an anti-sliding box, a ballast box and a compression grouting section; an area between a horizontal transverse brace and a horizontal diagonal brace of the four corners at the bottom of the pedestal foot jacket is provided with the anti-sliding box, and the anti-sliding box is inserted into mud on the surface of the sea bottom; the ballast box is arranged on the upper part of the anti-sliding box; the outer sides of the bottom of the pedestal foot jacket are provided with the four or more non-rock-socketed short piles, the non-rock-socketed short piles are driven into a rockfoundation face under a seabed, due to high end bearing capacity of the rock foundation surface, compression bearing capacity of the short piles is high, and uplift bearing capacity of the short piles is low; a main guiding pipe and a pile guiding pipe of the pedestal foot jacket are inserted into the mud; and the non-rock-socketed short piles are connected with the pile guiding pipe through thecompression grouting section. According to the shallow pile jacket structure, problems that traditional offshore booster station foundations are low in tensile bearing capacity of pile foundations, serious in horizontal deformation, low in anti-dumping and anti-sliding capacity of a jacket during construction, large in uneven settlement, and poor in reliability of the grouting section are solved.

Owner:POWERCHINA HUADONG ENG COPORATION LTD

Forming method of contact wire

InactiveCN113894168AMeet quality requirementsExtend your lifeWire straightening devicesDrawing diesWire rodEngineering

The invention discloses a forming method of a contact wire. The forming method comprises the following steps that S1, a raw material wire rod is loaded into an uncoiler; S2, the raw material wire rod is corrected and straightened through a straightening device to obtain a straightened wire rod; S3, the straightened wire rod is subjected to roller drawing deformation through a roller drawing die device, and the finished contact wire of a preset specification is obtained; and S4, the finished contact wire is coiled by a coiling machine. By means of the forming method, the large-length, high-strength and high-conductivity contact wire is formed in a roller drawing mode, the drawing force is reduced by about 2 / 3 when a roller drawing die is used for drawing the contact wire at the same deformation, the drawing force in the drawing process is greatly reduced, the forming speed is increased, the service life of a grinding tool is prolonged, the surface quality of the contact wire is improved, the problems that an original drawing die of the high-strength contact net wire is short in service life, low in production efficiency and poor in surface quality of the contact net wire due to large deformation resistance of a high-strength line blank are solved, and the quality requirement of the high-strength and high-conductivity contact net wire is met.

Owner:YANTAI WANLONG VACUUM METALLURGY

A seismic isolation structure with separate upper and lower floors inside a two-story station

ActiveCN111305263BAvoid damagePrevent excessive slippageArtificial islandsProtective foundationEngineeringSeismic isolation

The present invention provides a seismic isolation structure in which the upper layer and the lower layer are separated in a two-story station, including a middle plate, a side wall and a center column, the side wall is connected to the middle plate through horn legs, the middle plate is connected to the Frictional sliding bearings are arranged between the horn legs; the longitudinal beam of the middle plate is connected with the top of the central column by lead core shock-isolation bearings. The seismic isolation structure in which the upper layer and the lower layer are separated inside the two-story station can greatly reduce the damage degree of the two-story subway underground station structure in a strong earthquake, thereby improving the overall seismic performance of the two-story subway underground station structure.

Owner:NANJING TECH UNIV +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com