Convenient and rapid pressure grouting method adopting anchor rod

An anchor rod and grouting technology, which is applied in construction, sheet pile wall, infrastructure engineering and other directions, can solve the problems of affecting production safety, complicated installation and operation, and the rubber sleeve is easy to pop out, etc., and achieves improved pulling force and low cost. , The effect that is easy for workers to grasp

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

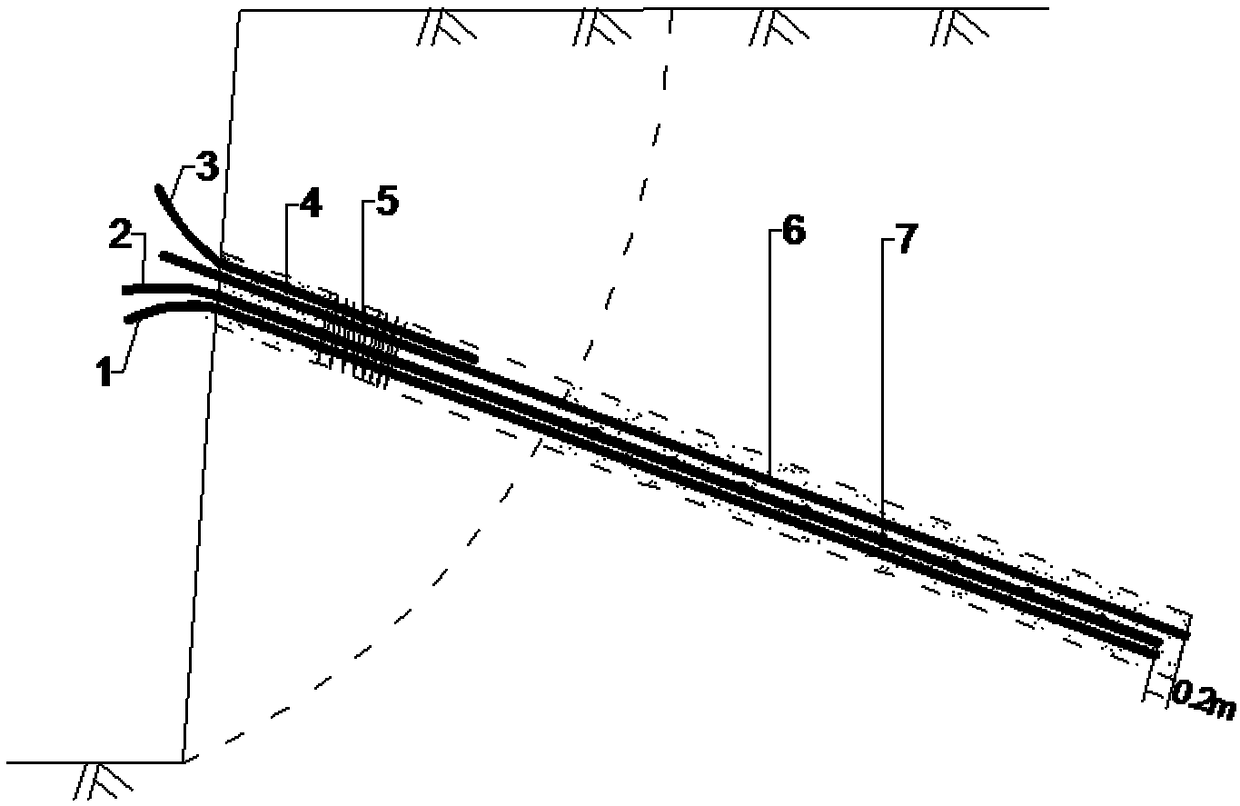

[0026] A convenient method for anchor bolt pressure grouting, such as figure 1 shown, including the following steps:

[0027] A. Determine the drilling position for drilling and clearing;

[0028] B. Anchor rod placement and sealing: Bind the primary grouting pipe 1, the secondary grouting pipe 2, the exhaust pipe 3 and the anchor rod 6, and use the woven bag 5 to tie the primary grouting pipe 1, the secondary grouting pipe 2, The exhaust pipe 3 and the anchor rod 6 are tightly wound and inserted into the drill hole. The distance between the top of the woven bag 5 and the hole of the drill hole is 2.0-3.0m. 150-250mm, within the length of the anchoring section, the side wall of the secondary grouting pipe 2 is provided with several grouting holes 7, and the open end of the bottom of the secondary grouting pipe 2 and the grouting hole 7 are sealed with tape. Prevent the secondary grouting pipe from being immersed in the slurry during the primary grouting; the diameter of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com