Photocuring three-dimensional printing material box and preparation method thereof, photocuring three-dimensional printing device and photocuring three-dimensional printing method

A 3D printing and light curing technology, applied in the field of 3D printing, can solve the problems of obvious horizontal stripes, increase the layering time, slow down the printing process, etc., so as to reduce the probability of pores being destroyed, increase the printing area, and increase the printing speed. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0042] In the second aspect, the present application also provides a method for preparing the above-mentioned light-cured 3D printing cartridge, including:

[0043] 1. Fix the non-porous fluoropolymer on the transparent bottom plate in the box to form a fluoropolymer film.

[0044] In some examples of the present application, fluoropolymer films were prepared and solvents were used to clean the fluoropolymer surface. Here the non-porous fluoropolymer film can be secured to a rigid backing using adhesive-backed fluoropolymer or non-adhesive fluoropolymer by a stretch film method.

[0045] 2. Plating fluorine-containing oil on the surface of the fluorine-containing polymer film to form a fluorine-containing oil film.

[0046] In some embodiments of the present application, a fluorine-containing oil film is coated on the surface of the non-porous fluorine-containing polymer film by spraying paint or paint coating process. When it is necessary to improve the parallelism of the s...

Embodiment 1

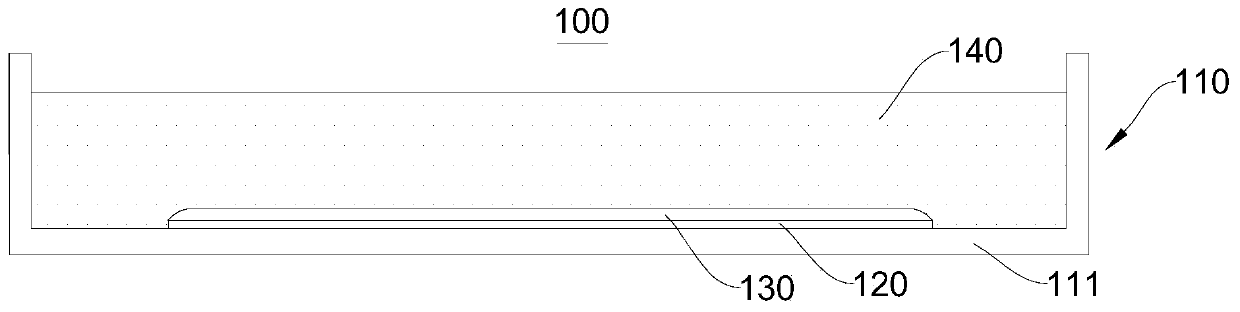

[0059] Please refer to image 3, this embodiment provides a light-curing 3D printing cartridge 100 , including a cartridge body 110 , a non-porous fluoropolymer film 120 and a fluorine-containing oil film 130 . The bottom of the box body 110 is a light-transmitting bottom plate 111 , and in this embodiment, all boxes 110 use a hard light-transmitting bottom plate 111 . The non-porous fluoropolymer film 120 is disposed on part of the inner surface of the light-transmitting bottom plate 111 , and in other embodiments of the present application, the non-porous fluoropolymer film 120 may cover the entire inner surface of the light-transmitting bottom plate 111 . The fluorine-containing oil film 130 is adsorbed on the surface of the non-porous fluorine-containing polymer film 120 away from the transparent bottom plate 111 . The photosensitive resin 140 is contained in the magazine as a raw material for photocuring molding. In this embodiment, the material of the non-porous fluoro...

Embodiment 2

[0061] This embodiment provides a light-curing 3D printing cartridge, the structure of which is the same as that of Embodiment 1, the only difference is that the material of the non-porous fluoropolymer film is perfluoroalkoxyalkane polymer, and the material of fluorine-containing oil film is perfluoroalkoxyalkane polymer. Fluoropolyether oil.

PUM

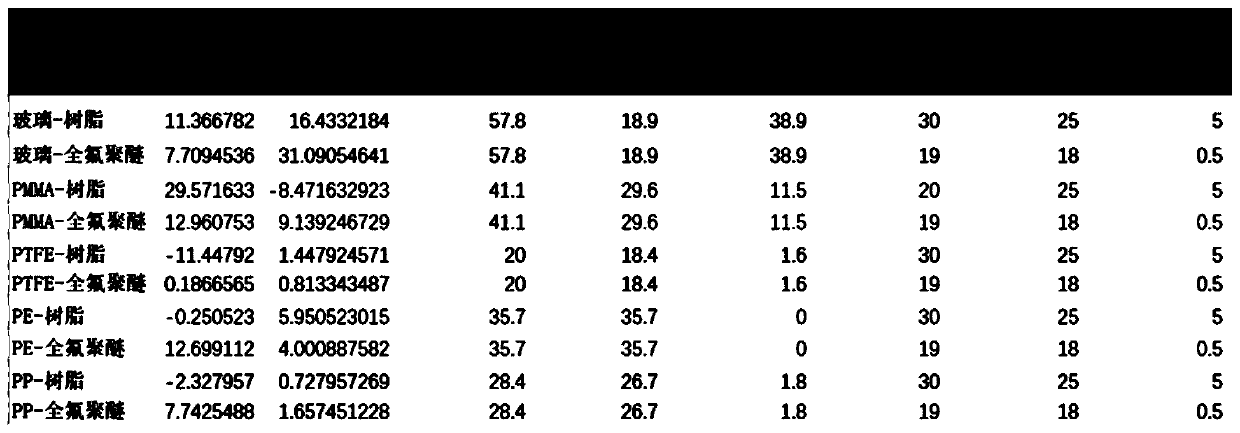

| Property | Measurement | Unit |

|---|---|---|

| Kinematic viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com