Method for producing Nb3Al superconducting wire precursor through elastic plastic processing

A superconducting wire and precursor technology, applied in cable/conductor manufacturing, circuits, electrical components, etc., can solve the problems of wire breakage, large difference in melting point, stress relief annealing, etc., so as to slow down work hardening and improve plastic deformation ability. , the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

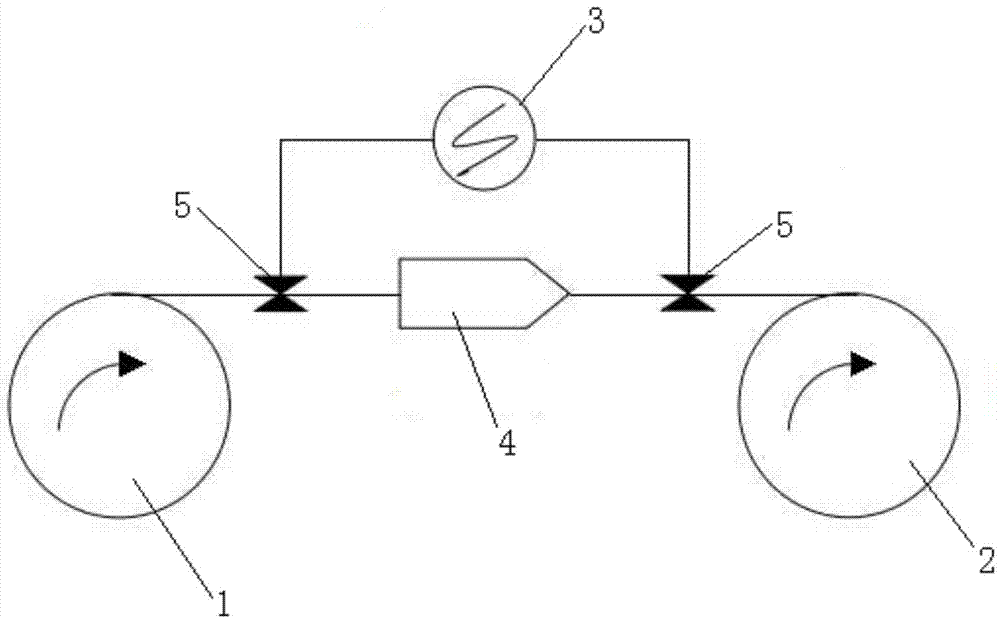

Method used

Image

Examples

Embodiment 1

[0032] The first step is to prepare Al rods, Nb tubes and Cu tubes with a length of 500 mm. The diameter of the Al rod is 8 mm, the inner diameter of the Nb tube is 8 mm, the outer diameter is 16 mm, the inner diameter of the Cu tube is 16 mm, and the outer diameter is 21 mm. Insert the Al rod into the Nb tube to obtain a Nb / Al composite rod, and then insert the Nb / Al composite rod into the Cu tube to obtain a Cu / Nb / Al composite rod;

[0033] In the second step, the composite rods obtained above are drawn through the adjusted electroplastic drawing device for multiple passes. The electroplastic drawing process is: the voltage is 110V, the peak current of the power supply is 1000A, and the pulse width is 60μs. The area length is 300mm, the drawing rate is 20m / min, the pass processing rate is 10%, the pulse frequency is set to 230Hz, and the diameter is drawn to 10mm according to this process; then the pulse frequency is increased to 300Hz, and further drawn to 5mm according to t...

Embodiment 2

[0037] The first step is to prepare Al rods, Nb tubes and Cu tubes with a length of 800mm. The diameter of the Al rod is 5mm, the inner diameter of the Nb tube is 5mm, and the outer diameter is 10mm, and the inner diameter of the Cu tube is 10mm, and the outer diameter is 15mm. Inserting the Al rod into the Nb tube to obtain a Nb / Al composite rod, and then inserting the Nb / Al composite rod into the Cu tube to obtain a Cu / Nb / Al composite rod;

[0038] In the second step, the composite rod obtained above is drawn through the adjusted electroplastic drawing device for multiple passes. The electroplastic drawing process is: the voltage is 110V, the peak current of the power supply is 1000A, and the pulse width is 60μs. The length of the processing area is 300mm, the drawing rate is 15m / min, the pass deformation rate is 15%, the pulse frequency is set to 230Hz, and the diameter is drawn to 10mm according to this process; then the pulse frequency is increased to 300Hz, and the diamet...

Embodiment 3

[0042] The first step is to prepare Al rods, Nb tubes and Cu tubes with a length of 1000 mm, wherein the diameter of the Al rod is 10 mm, the inner diameter of the Nb tube is 10 mm, the outer diameter is 20 mm, and the inner diameter of the Cu tube is 20 mm, and the outer diameter is 25 mm. Inserting the Al rod into the Nb tube to obtain a Nb / Al composite rod, and then inserting the Nb / Al composite rod into the Cu tube to obtain a Cu / Nb / Al composite rod;

[0043] In the second step, the composite rods obtained above are drawn through the adjusted electroplastic drawing device for multiple passes. The electroplastic drawing process is: the voltage is 110V, the peak current of the power supply is 1000A, and the pulse width is 60μs. The area length is 300mm, the drawing rate is 10m / min, the pass deformation rate is 12%, and the pulse frequency is set to 230Hz. According to this process, the diameter is drawn to 12mm, the outer layer of Cu is corroded, and the wire rod is rolled in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com