Small-pullout-force optical fiber connector shell and optical fiber connector using same

A technology for optical fiber connectors and housings, which is applied in the field of optical cable connection equipment, can solve problems such as large pull-out force, and achieve the effect of solving large pull-out force and reducing pull-out force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

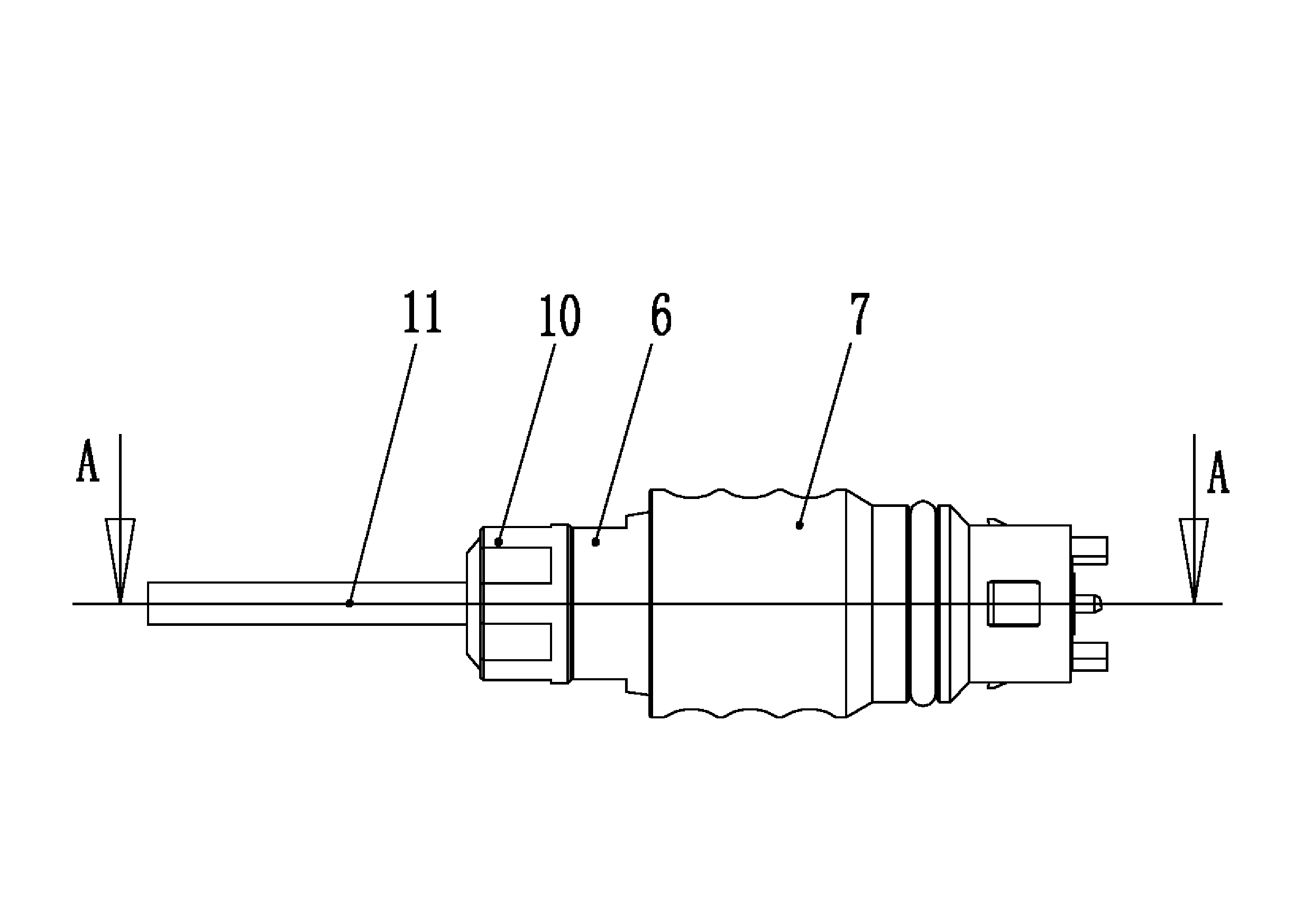

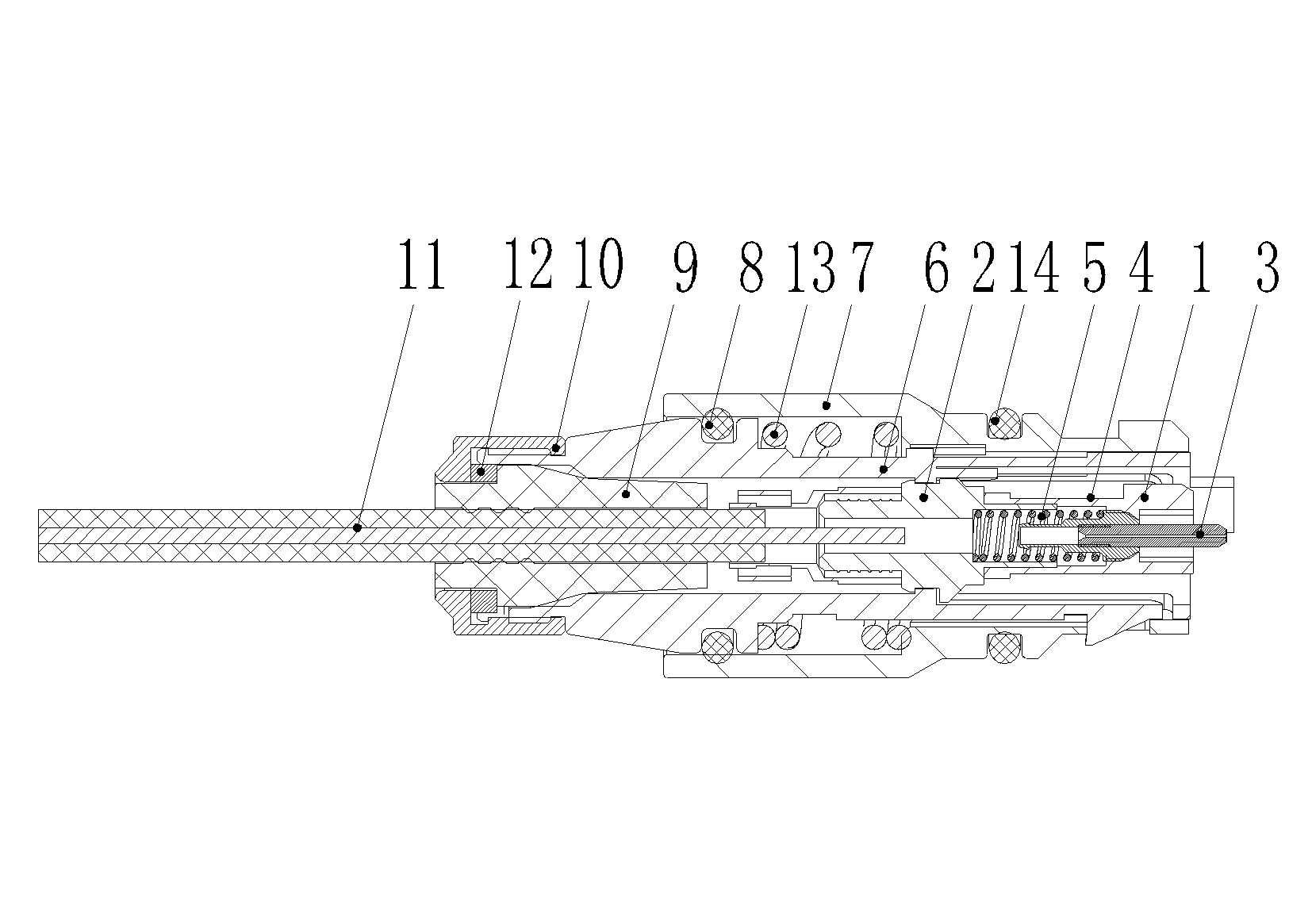

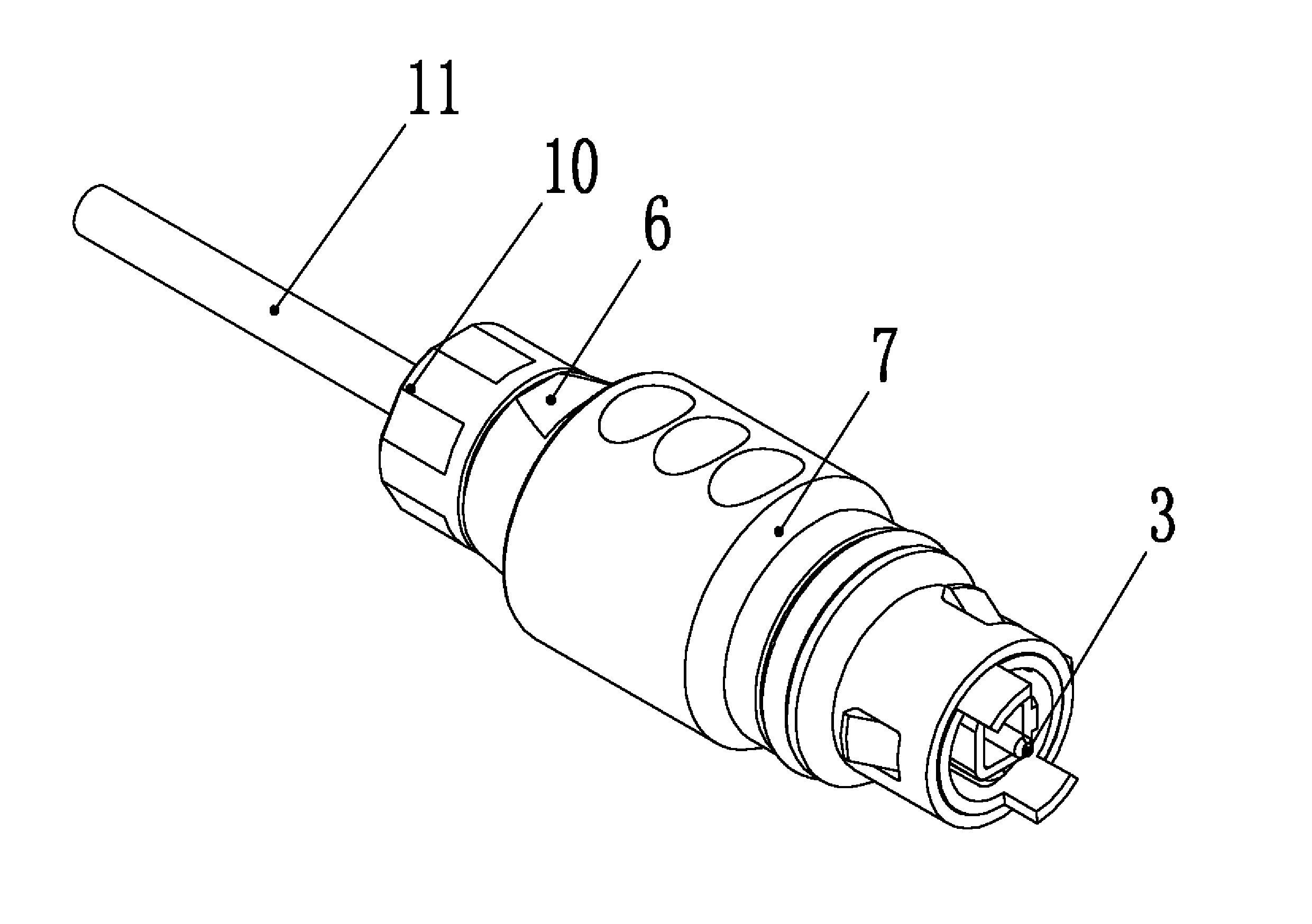

[0032] Embodiment 1 of the fiber optic connector, such as Figure 1-16 As shown, it consists of a housing and a pin assembly inside the housing.

[0033] Pin components (such as Figure 4-8 ) has a pin housing. The pin housing is composed of a front housing 1 and a rear housing 2. The outer contour of the front housing 1 is rectangular and has an inner hole extending axially. The inner hole of the front housing 1 There is a baffle plate 1-1, the baffle plate 1-1 has a through hole through the front and back, and the pin 3 is installed in the through hole along the axial movable guide, the rear end of the pin 3 is provided with a pin seat 4, and the pin seat 4 is arranged on the back end of the pin The front end of the needle seat 4 cooperates with the rear side of the baffle plate 1-1 to stop and limit, and the rear end is provided with a buffer spring 5; the front housing 1 is provided with a front housing hanging hole 1-2 on its circumference, which The through hole in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com