Rapid photocuring 3D printer material box and 3D printer

A 3D printer and photo-curing technology, which is applied in 3D object support structures, accessories for processing main materials, additive manufacturing, etc., can solve the problem of increased pulling force between the printing layer and the bottom surface of the material box, PDMS cannot continue to replenish oxygen, and the printing effect is not good. Good and other problems, to achieve the effect of good printing effect, small error and low pulling force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

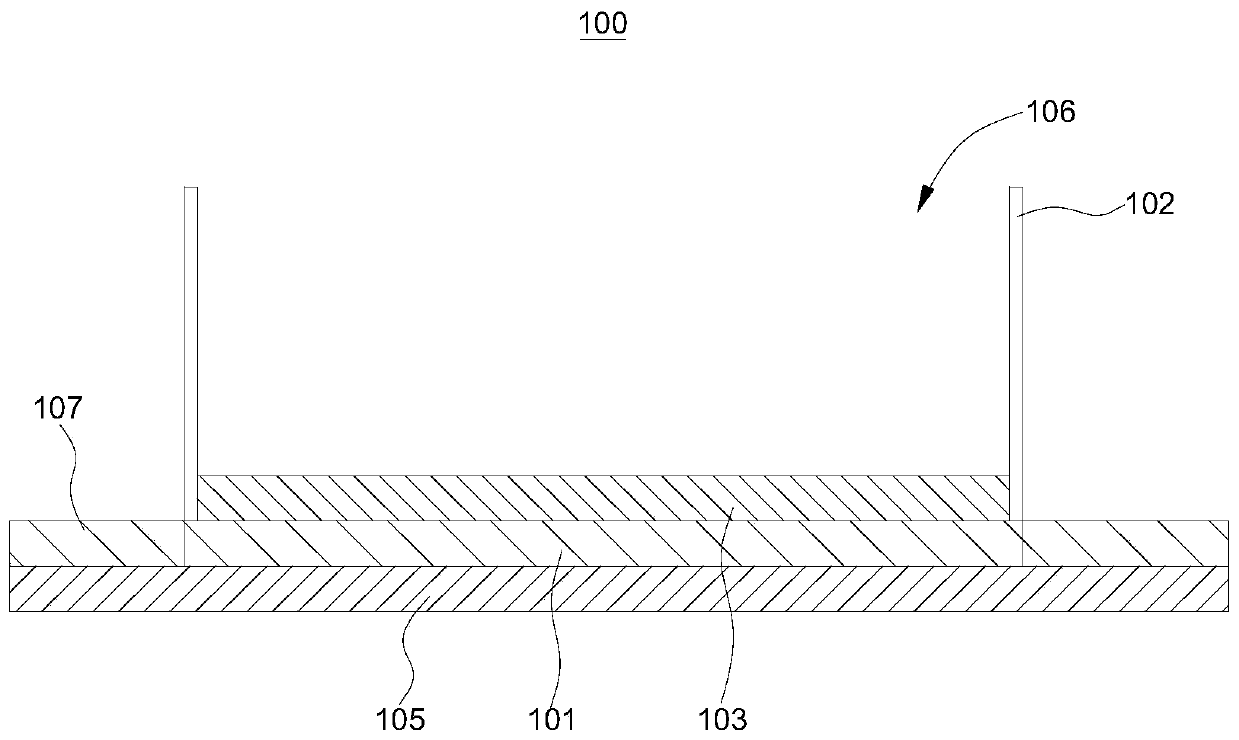

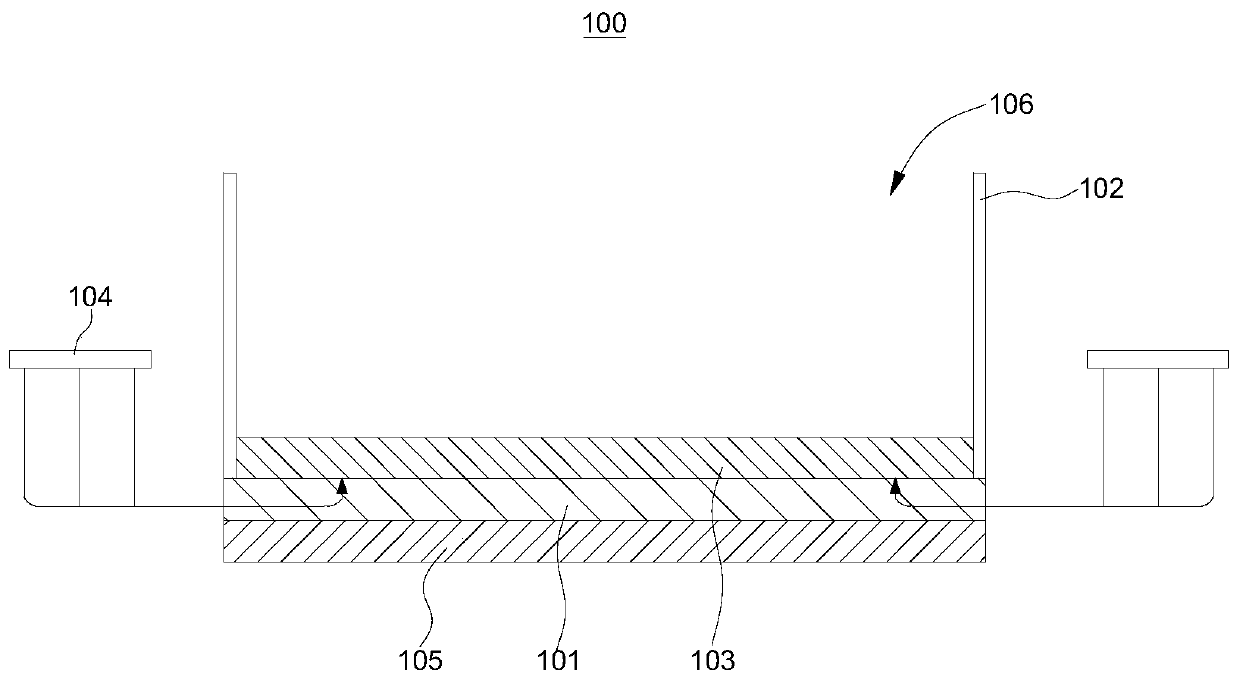

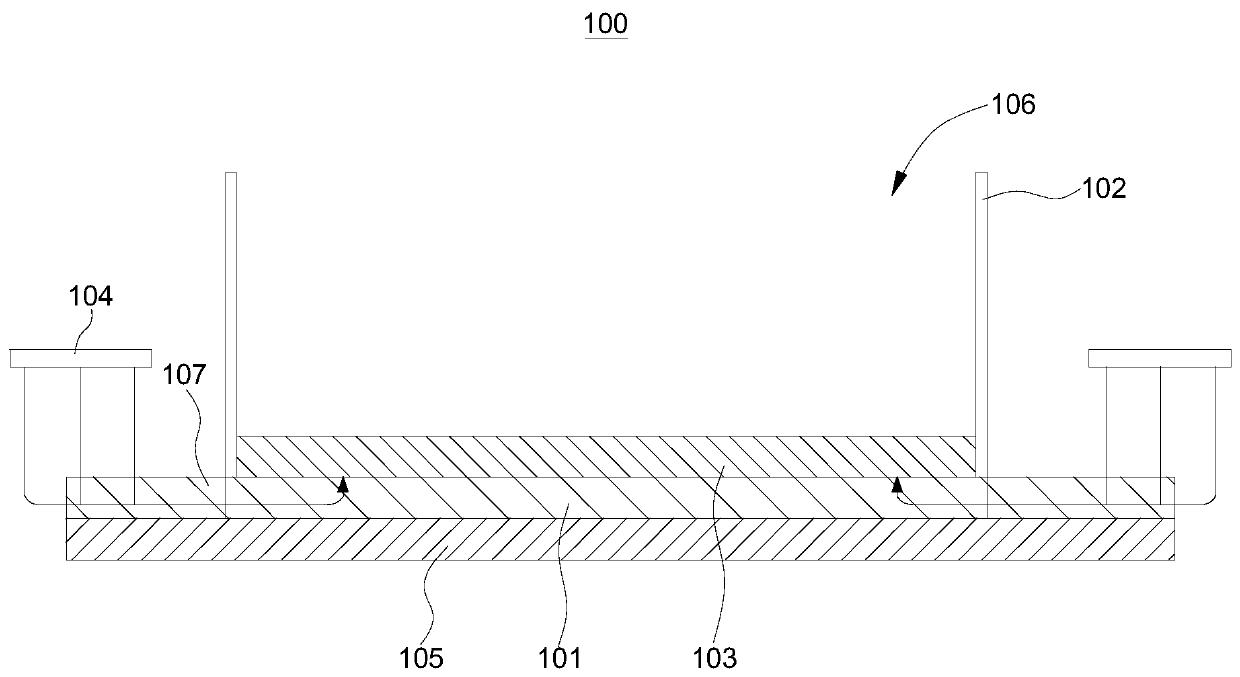

[0037] Please refer to figure 1 , the present embodiment provides a rapid photocuring 3D printer cartridge 100, which includes a curing inhibitor delivery layer 101, a resin tank side wall 102 and a curing inhibitor supply part.

[0038]Specifically, the curing inhibitor delivery layer 101 is located at the bottom of the resin tank sidewall 102 , so that the resin tank sidewall 102 and the curing inhibitor delivery layer 101 enclose a closed resin tank 106 . The curing inhibitor supply part can supply the curing inhibitor to the curing inhibitor delivery layer 101 (in this application, it refers specifically to oxygen, which can mix with the resin to form oxygen inhibition phenomenon). The curing inhibitor enters the resin in the resin tank 106 well and continuously from the curing inhibitor delivery layer 101, and the resin in the oxygen-inhibited part will not be cured. At this time, the solid-liquid separation of the cured resin and the uncured resin, The pulling force is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com