Film coating device for steel stranded steel wire drawing and using method

A coating device and technology for steel strands, which are applied in the field of steel strand steel wire production and processing, can solve the problems of reducing the toughness and strength of steel wires, unable to achieve continuous pay-off, and destroying the molecular structure of wire rods, so as to reduce the pulling force. , the effect of improving life expectancy and abundant resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described in detail below in conjunction with the accompanying drawings and through specific embodiments.

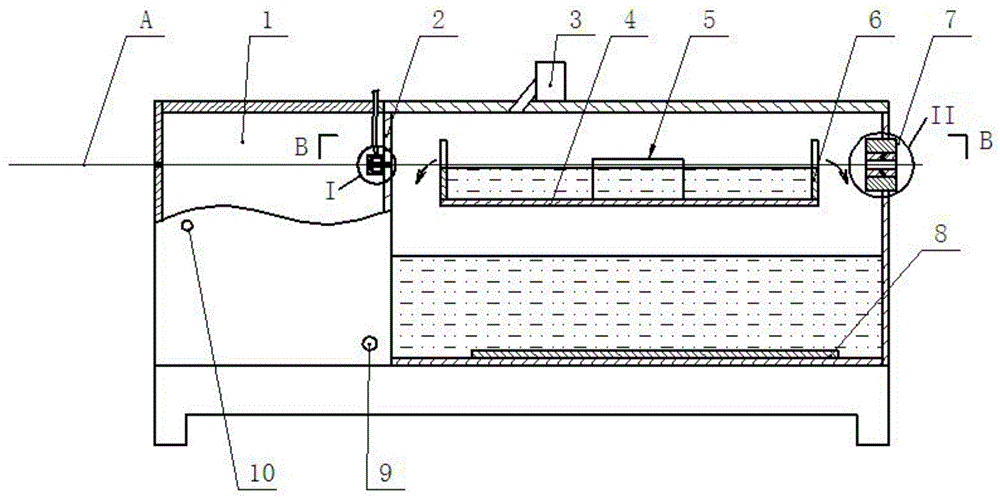

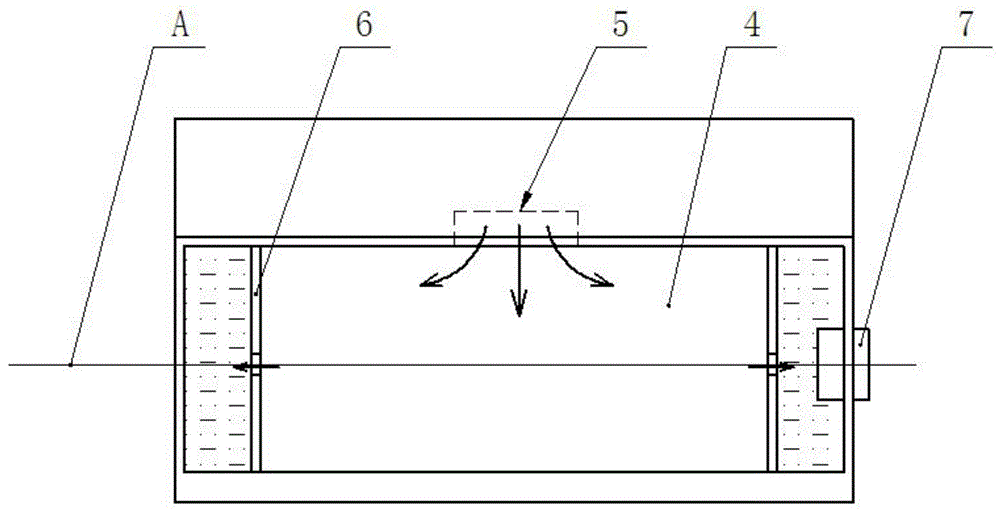

[0031] A coating device for wire drawing of steel strands, such as figure 1 , figure 2 As shown, it includes a box body 1, a cleaning mechanism and a film coating mechanism. A partition 2 is installed in the box body, thereby dividing the box body into a cleaning mechanism at the left side of the wire inlet and a film coating mechanism at the right side of the box.

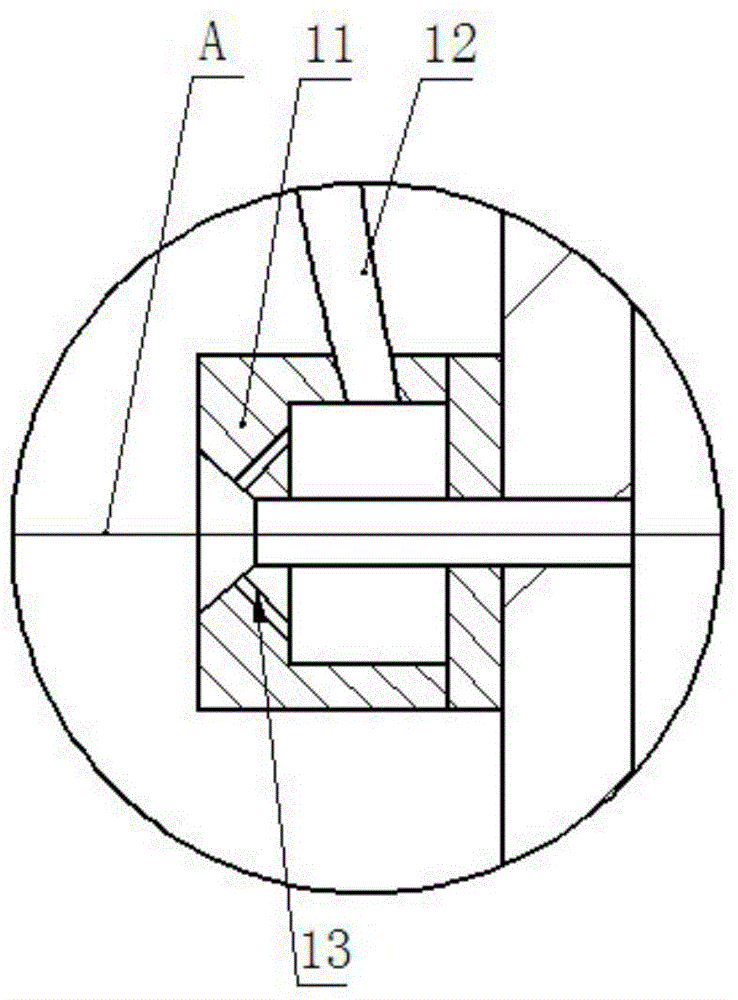

[0032] 1. The cleaning mechanism includes a high-pressure water spray assembly, a sewage discharge port 9 and an overflow port 10. The sewage discharge port is installed on the lower part of the front surface of the box body, and the overflow port is installed on the top of the front surface of the box body. The high-pressure water spray assembly Installed on the left side of the bulkhead. The structure of the high-pressure water spray assembly is as follows ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com