Offshore wind power combination foundation

A combined foundation and offshore wind power technology, applied in infrastructure engineering, construction, etc., can solve the problems of increasing foundation cost and construction period, main leg distance and steel pipe pile length, and increasing wave load, so as to improve the anti-overturning ability. , The effect of reducing the basic cost and reducing the pulling force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

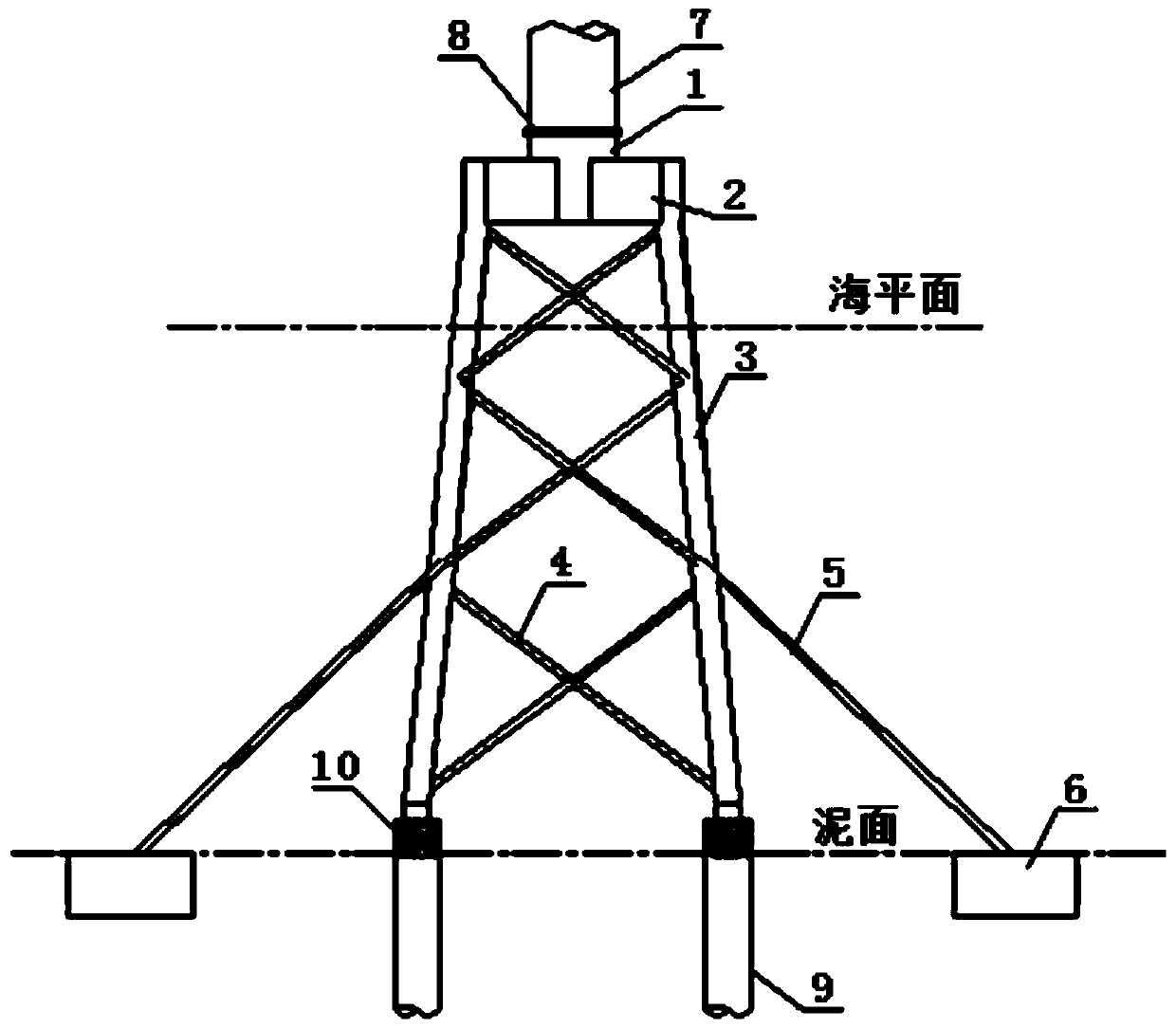

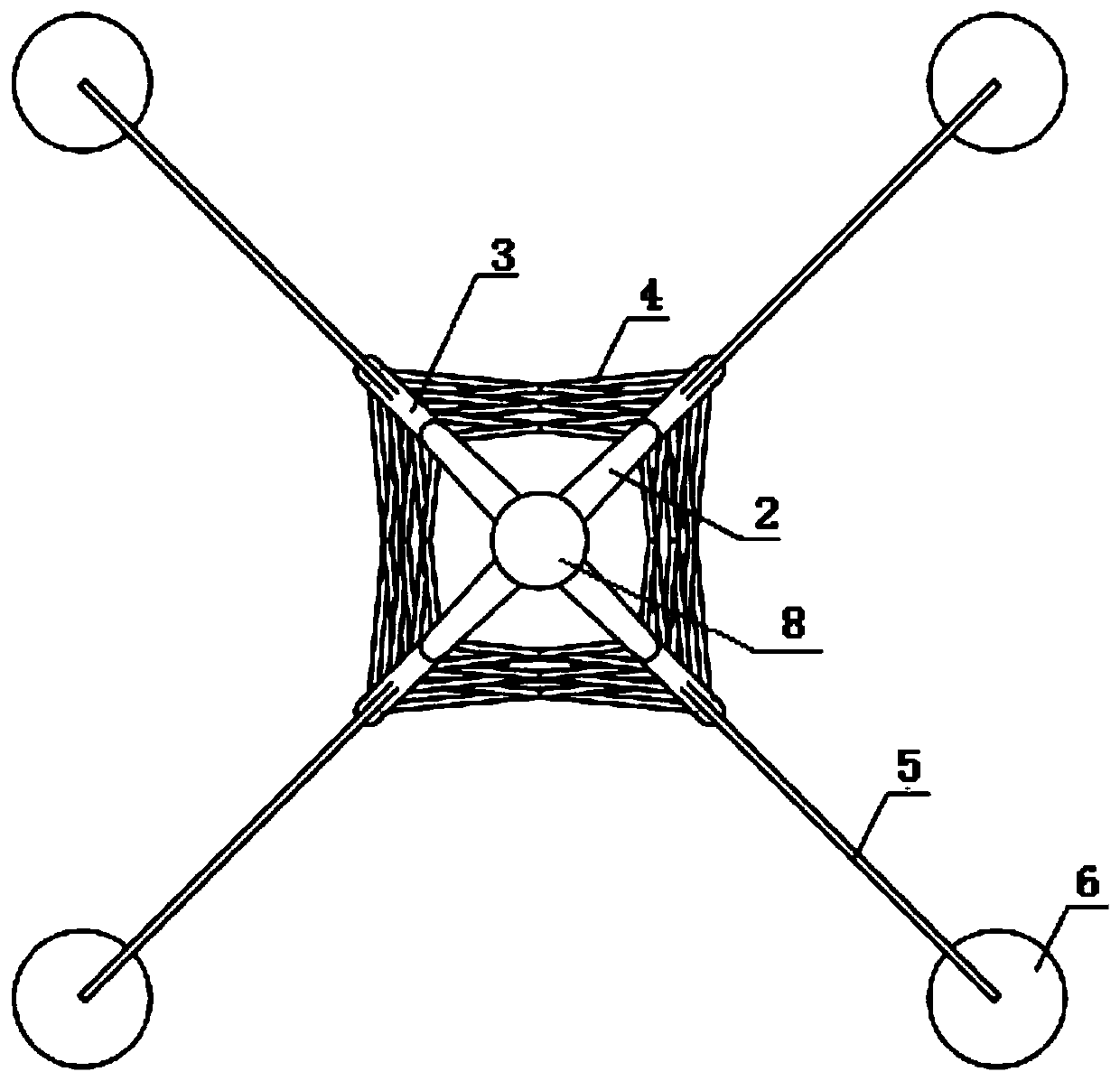

[0017] Such as figure 1 As shown, an offshore wind power composite foundation of the present invention includes a jacket, steel pipe piles 9, suction cylinder 6 and steel cables 5, the top of the jacket is provided with a top steel beam 2, and the top steel beam 2 is provided with a transition section 1, The bottom of the fan tower 7 is fixedly connected to the transition section 1 through a flange 8 or grouting to realize the fixed installation of the fan and the jacket. The bottom of the jacket is fixedly connected to the steel pipe pile 9 buried in the seabed. The bottom of the jacket is fixedly connected through the grouting section 10 to realize the fixed installation of the overall structure of the jacket on the seabed. A plurality of suction cylinders 6 are evenly distributed on the circumference centered on the fan tower 7 , and the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com