Li-SOCl2 cell anode powder mixing method

A thionyl chloride battery and positive electrode technology, applied in the direction of electrode carrier/current collector, can solve the problems of difficulty in controlling the extensibility of PTFE, increasing process complexity, high energy consumption, etc., and achieve discharge platform and capacity uniformity Good, overcome the effect of uneven mixing and uniform mixing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

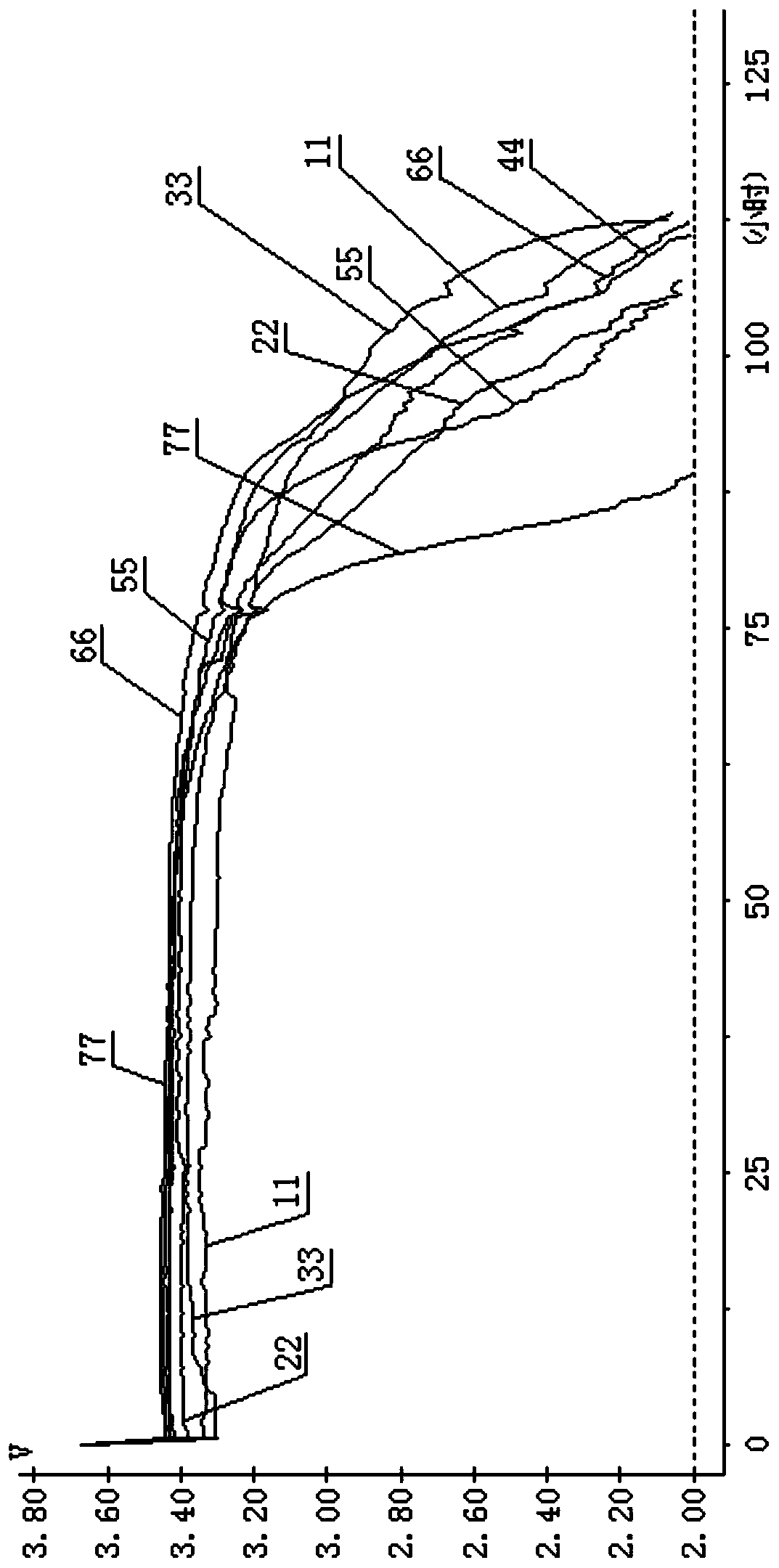

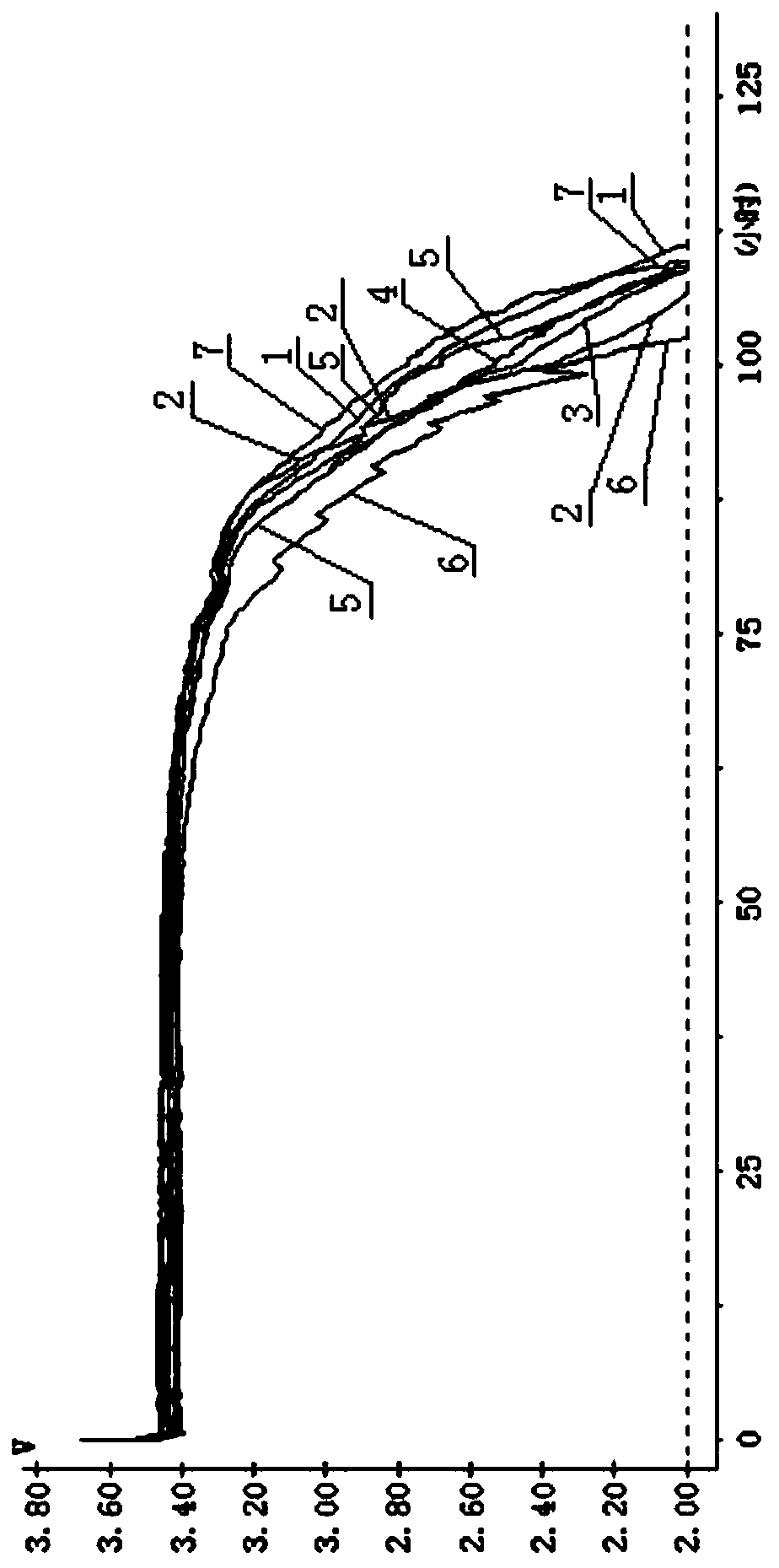

Embodiment 1

[0039] Lithium-thionyl chloride battery positive electrode and powder method, and the powder formula is: acetylene black: 8Kg, polytetrafluoroethylene emulsion: 1.0Kg, copper powder: 1.05Kg, isopropanol: 11Kg, deionized water: 25Kg.

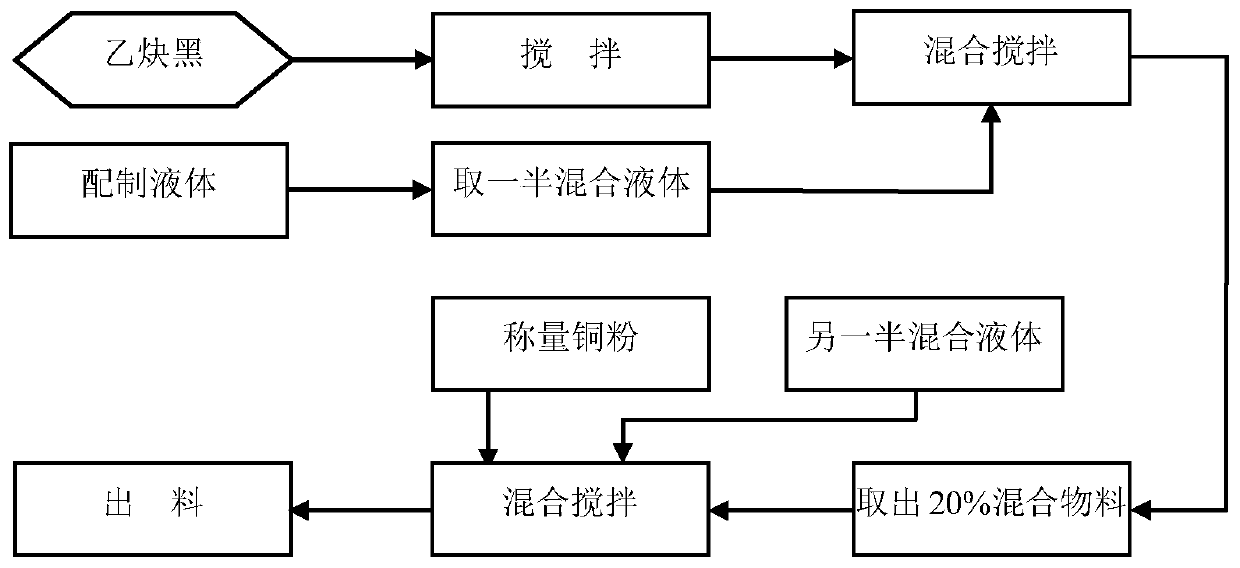

[0040] Its and powder method comprises the steps:

[0041] Step 1: Add the acetylene black of the stated weight into the blender and stir at room temperature of 25±5°C and humidity of 50%±20%;

[0042] Step 2: Mix the polytetrafluoroethylene emulsion, isopropanol and deionized water according to the weight to obtain a mixed solution, take half the weight of the mixed solution and add it to a blender, stir and mix to obtain a mixed powder;

[0043] Step 3: After stirring for 15 minutes, release about 20% of the total amount of mixed powder from the outlet at the bottom of the mixer.

[0044] Step 4: Add the metal powder of the stated weight into the blender evenly from the inlet of the blender, then add the mixed powder released in step 3 from th...

Embodiment 2

[0047] Lithium-thionyl chloride battery positive electrode and powder method, and the powder formula is: acetylene black: 10Kg, polytetrafluoroethylene emulsion: 1.5Kg, copper powder: 1.00Kg, isopropanol: 10Kg, deionized water: 20Kg.

[0048] Its kneading powder method is with embodiment 1.

Embodiment 3

[0050] Lithium-thionyl chloride battery positive electrode and powder method, and the powder formula is: acetylene black: 12Kg, polytetrafluoroethylene emulsion: 2.0Kg, copper powder: 0.95Kg, isopropanol: 7Kg, deionized water: 15Kg.

[0051] Its kneading powder method is with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com