Basket ring spring hook butt welding machine

A spring hook, butt welding machine technology, applied in welding equipment, resistance welding equipment, metal processing equipment and other directions, can solve the problems of inconvenient positioning of the spring hook, low production efficiency, insufficient welding seam strength, etc., and achieve stable and reliable solder joints. Low cost and good quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

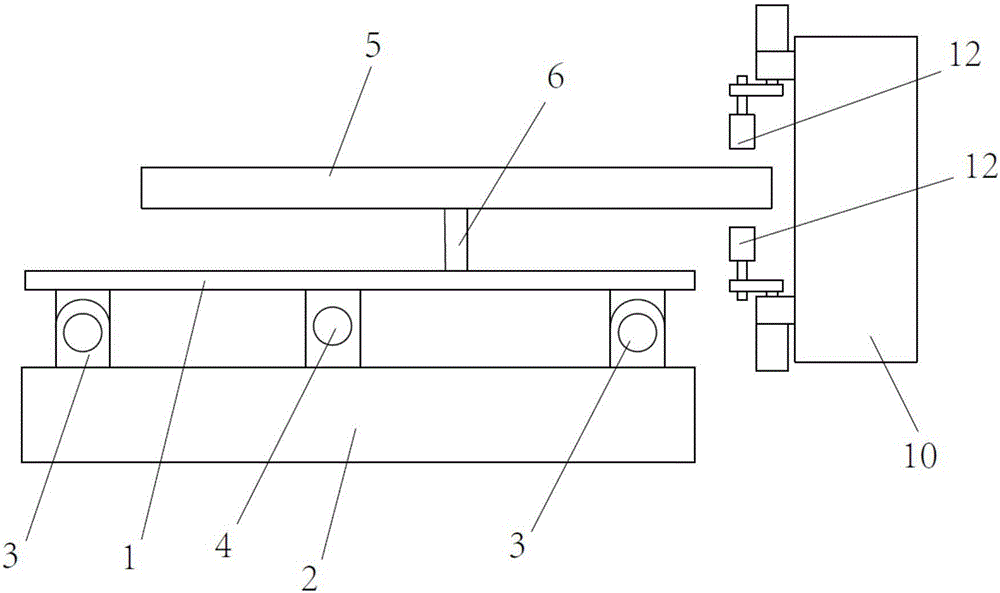

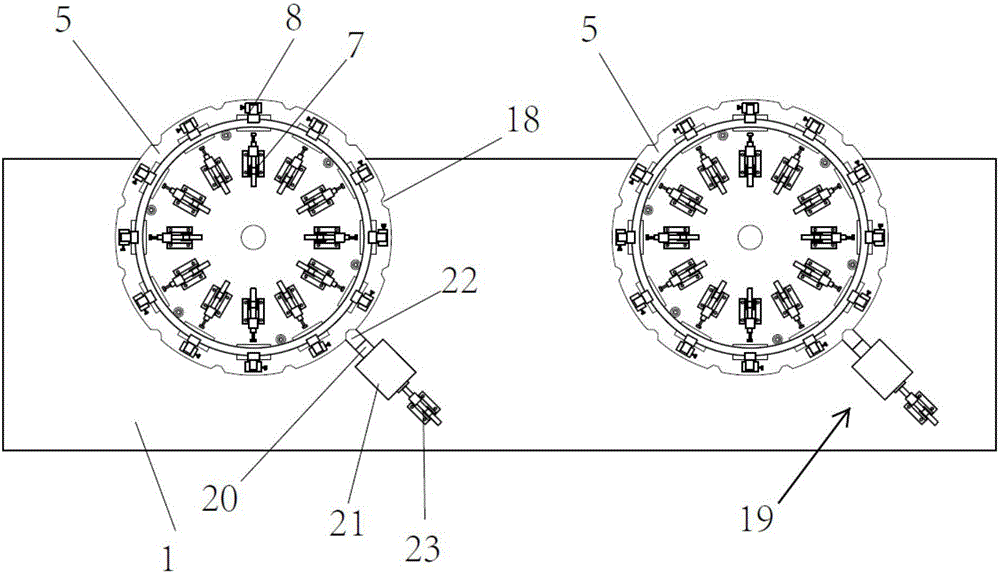

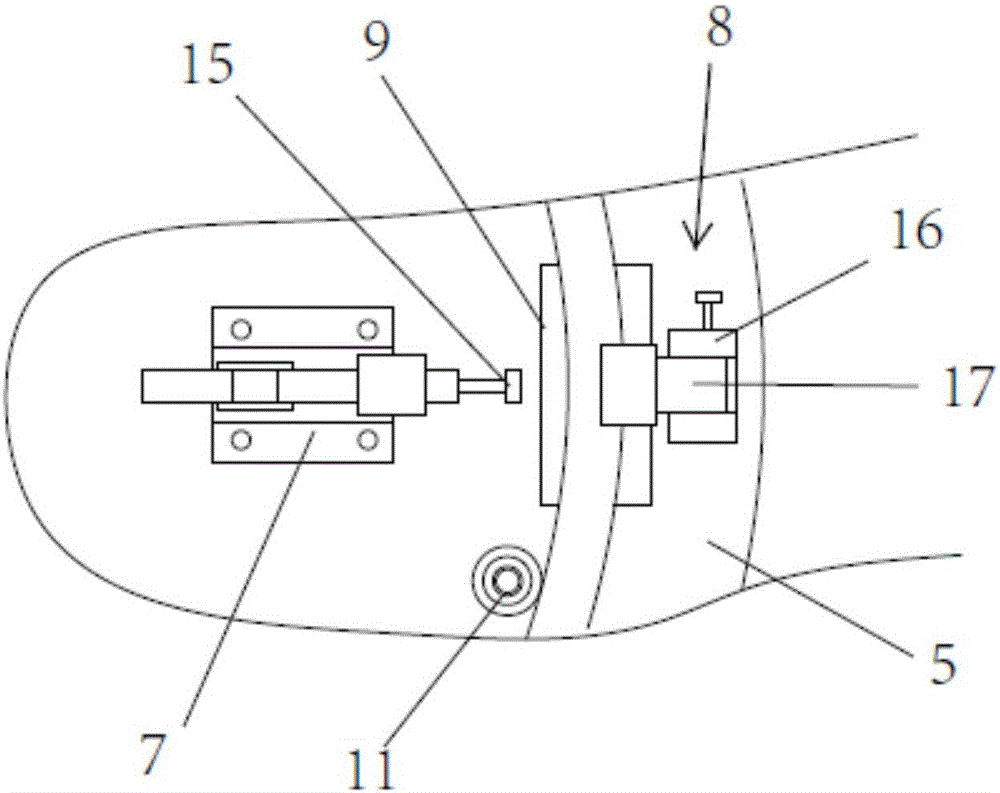

[0029] refer to Figure 1 to Figure 5 As shown, a butt welding machine for a basket spring hook includes a bottom plate 1, the bottom plate is arranged on a mobile support 2, a first guide assembly 3 and a transmission mechanism 4 are arranged between the bottom plate and the mobile support, and the surface of the bottom plate is arranged along the moving direction. There are two loading discs 5, the loading discs are connected to the bottom plate through the rotating assembly 6, a number of first quick clamps 7 are arranged on the surface of the loading disc along the same circumference, and the surface between the several first quick clamps and the outer circumference of the loading disc A number of abutment positioning parts 8 are also provided along the same circumference. The first quick clamp and the abutment positioning part cooperate to clamp the spring hook. There is a butt welding avoidance groove 9, and a butt welding machine 10 is arranged on one side of the loadin...

Embodiment 2

[0037] The difference between the second embodiment and the first embodiment is that the rotating component is an indexing plate, and the rotation can be easily realized by controlling the indexing plate, so as to achieve better automation performance and reduce labor force.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com