Frame for manufacturing yeast and frame type yeast manufacturing fermentation method

A technology of shelves and bent blanks, which is applied in the preparation of alcoholic beverages, etc., to achieve the effects of easy production, simple turning operation, and easy ventilation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

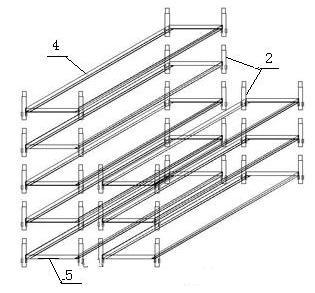

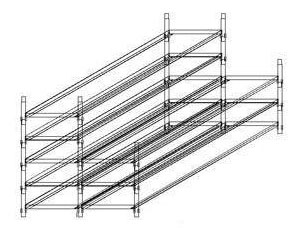

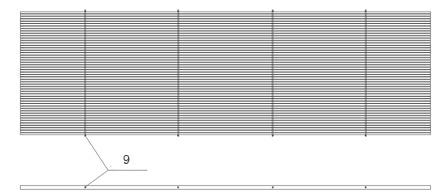

[0049] 1. Make the curved frame

[0050] It is designed as five floors and ten columns, the layer distance is 300mm, and the length and width of each column is 2220×680 mm. Each layer is paved with bamboo blocks, and its size is 2200×660×20 mm. The combination of layers and columns adopts pendants and public piles connect.

[0051] 1. Cutting. Cut the steel to the required size with a cutting machine:

[0052] Galvanized steel: 50×3 mm, 300 mm×110 pieces, 40×4.5 mm, 100 mm×110 pieces;

[0053] 15×3 mm, 50 mm×440 pieces.

[0054] Connecting angle steel: galvanized angle steel ∠50×4 mm, 2200 mm×100 pieces, ∠50×4 mm, 680 mm×100 pieces

[0055] Connect the pendant, 14 plain steel: 30 mm x 100 pieces, 60 mm x 400 pieces.

[0056] Reinforced connection block: -40×4 galvanized flat iron: 670 mm×50 pieces

[0057] 2. Drilling. Drill at the center of ∠50×4 galvanized angle steel with a length of 2200mm 14.5 holes, ea...

Embodiment 2

[0077] 1. Make the shelf used for koji making

[0078] The design is six layers and twelve columns, the layer distance is 280mm, the length and width of each column is 2200×680 mm, and the size of each layer is 2180×660×20 mm. The combination of layers and columns is connected by pendants and public piles .

[0079] 1. Cutting. Cut the steel to the required size with a cutting machine:

[0080] Galvanized steel: 50×3, 280 mm×156 pieces, 40×4.5, 100 mm×156 pieces

[0081] 15×3, 50 mm×624 pieces,

[0082] Connecting angle steel: galvanized angle steel ∠50×4, 2180×144 pieces, ∠50×4, 680×144 pieces

[0083] Connect the pendant, 14 plain steel: 30×144 pieces, 60×576 pieces.

[0084] Reinforced connection block: -40×4 galvanized flat iron: 670×72 pieces

[0085] 2. Drilling. Drill at the center of ∠50×4 galvanized angle steel with a length of 2180mm 14.5 holes, each drilled at 20mm at both ends of -40×4 galvanized flat iron 14.5 holes; in 50×3 galvanized steel...

Embodiment 3

[0103] 1. Make the shelf used for koji making

[0104] The design is 4 layers and 9 rows, the layer distance is 350mm, the length and width of each row is 2240×700 mm, and the size of each layer is 2220×680×20 mm. The combination of layers and rows is connected by pendants and public piles.

[0105] 1. Cutting. Cut the steel to the required size with a cutting machine:

[0106] Galvanized steel: 50×3, 350 mm×104 pieces, 40×4.5, 100 mm×104 pieces

[0107] 15×3, 50 mm×416 pieces,

[0108] Connecting angle steel: galvanized angle steel ∠50×4, 2220×72 pieces, ∠50×4, 700×72 pieces

[0109] Connect the pendant, 14 plain steel: 30×72 pieces, 60×288 pieces.

[0110] Reinforced connection block: -40×4 galvanized flat iron: 690×36 pieces

[0111] 2. Drilling. Drill at the center of ∠50×4 galvanized angle steel with a length of 2220mm 14.5 holes, each drilled at 20mm at both ends of -40×4 galvanized flat iron 14.5 holes; in 50×3 galvanized steel pipe 20 mm at one en...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com