Pipeline cutting equipment on basis of inner side wall expansion clamping principles

A pipe cutting and principle technology, applied in the direction of metal processing equipment, clamping, large fixed members, etc., can solve the problems that the blade cannot completely penetrate the pipe at one time, the pipe section is uneven, and the cutting effect is poor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in various ways defined and covered by the claims.

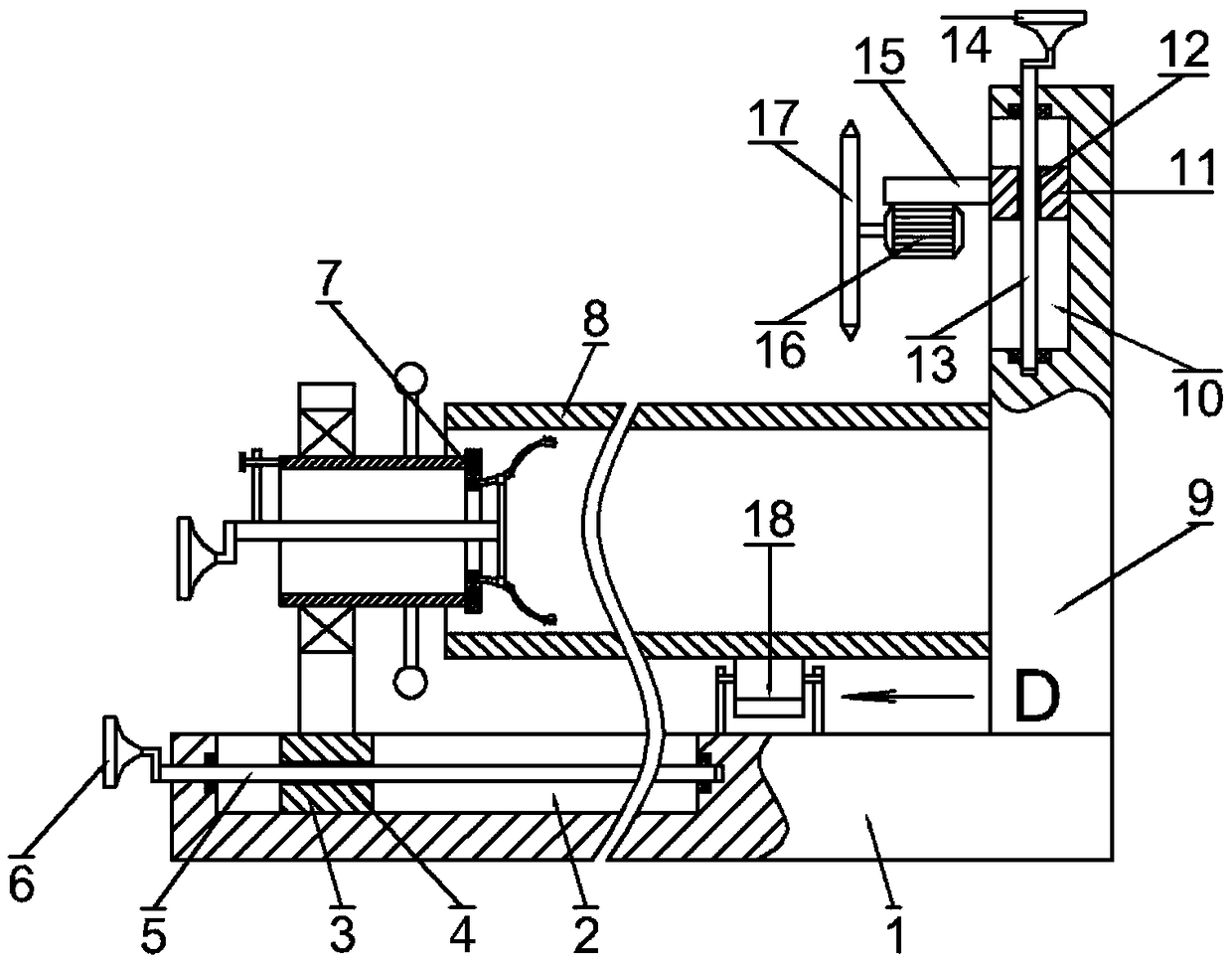

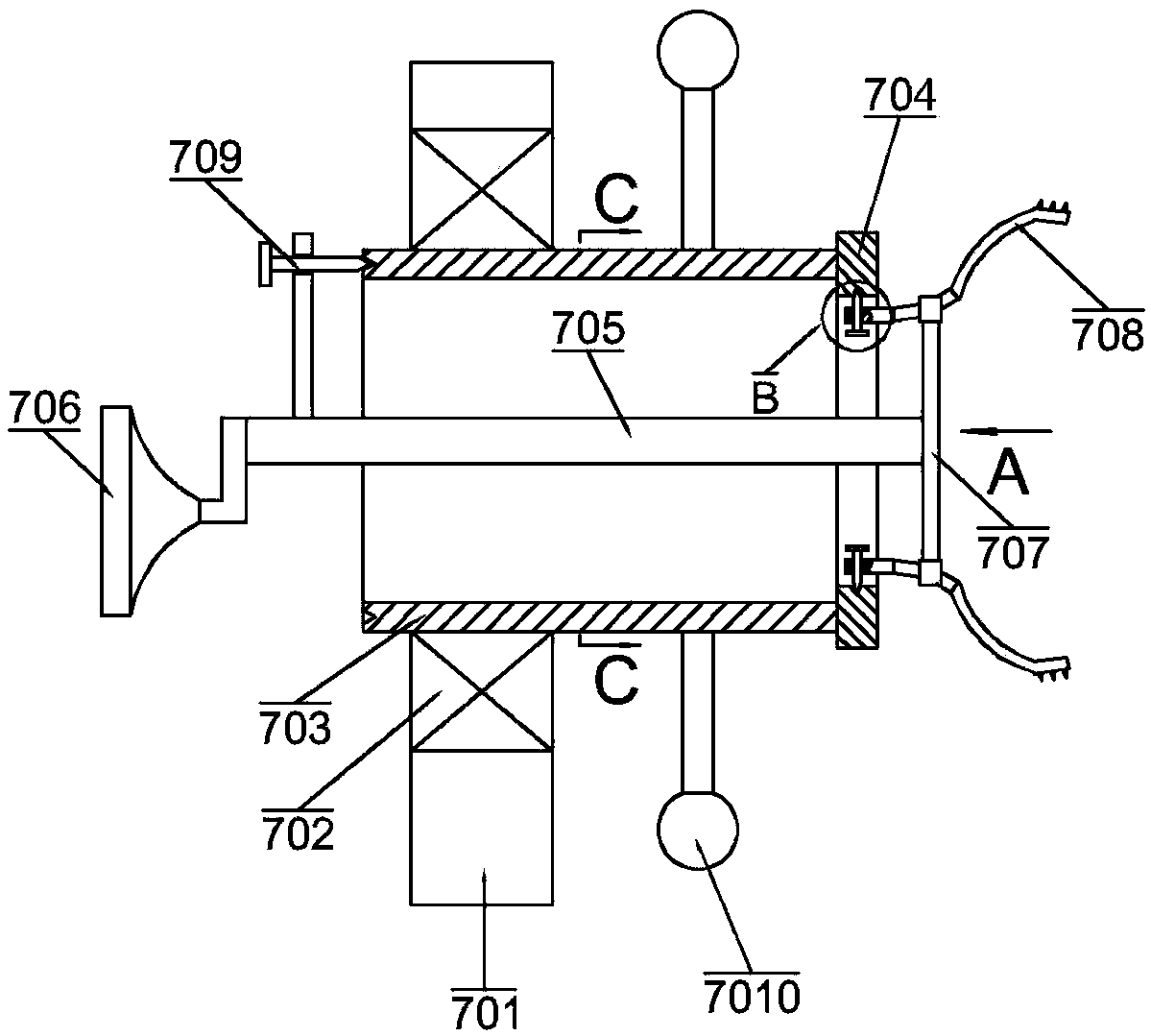

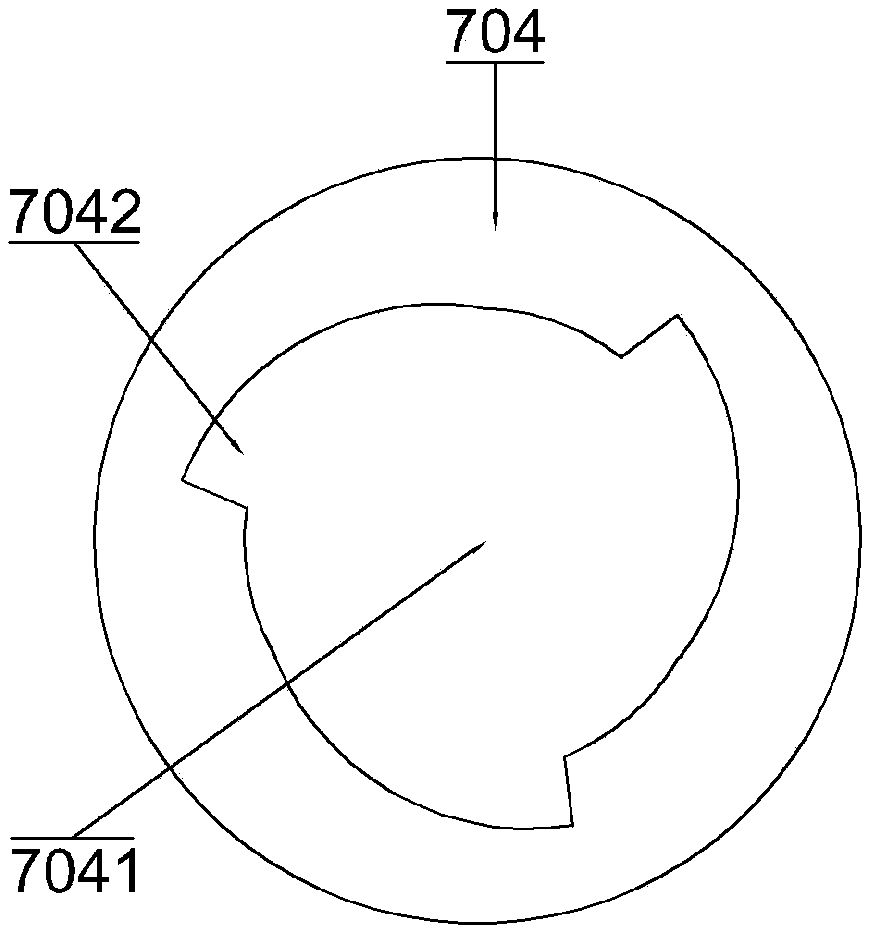

[0035] see figure 1 , in this embodiment, a pipe cutting device based on the expansion clamping principle of the inner side wall, including a bottom plate 1, a first moving groove 2 with an opening facing upwards is opened on the bottom plate 1, and a first moving groove 2 is arranged in the first moving groove 2 The first moving block 3, the first moving block 3 is provided with a first threaded through hole 4, the first threaded through hole 4 is internally threaded with a first threaded rod 5, the two ends of the first threaded rod 5 are connected to the first moving groove 2 The two ends are rotationally connected, the left end of the first threaded rod 5 is fixedly connected with the first handle 6, the upper side of the first moving block 3 is fixedl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com