Membrane separation process for lead-zinc smelting wastewater

A membrane separation and process technology, applied in the fields of metallurgical wastewater treatment, water pollutants, water/sewage treatment, etc., can solve the problems of low wastewater recovery rate and poor recovered water quality, and achieve high wastewater recovery rate, good reuse water quality, Simple process and economical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

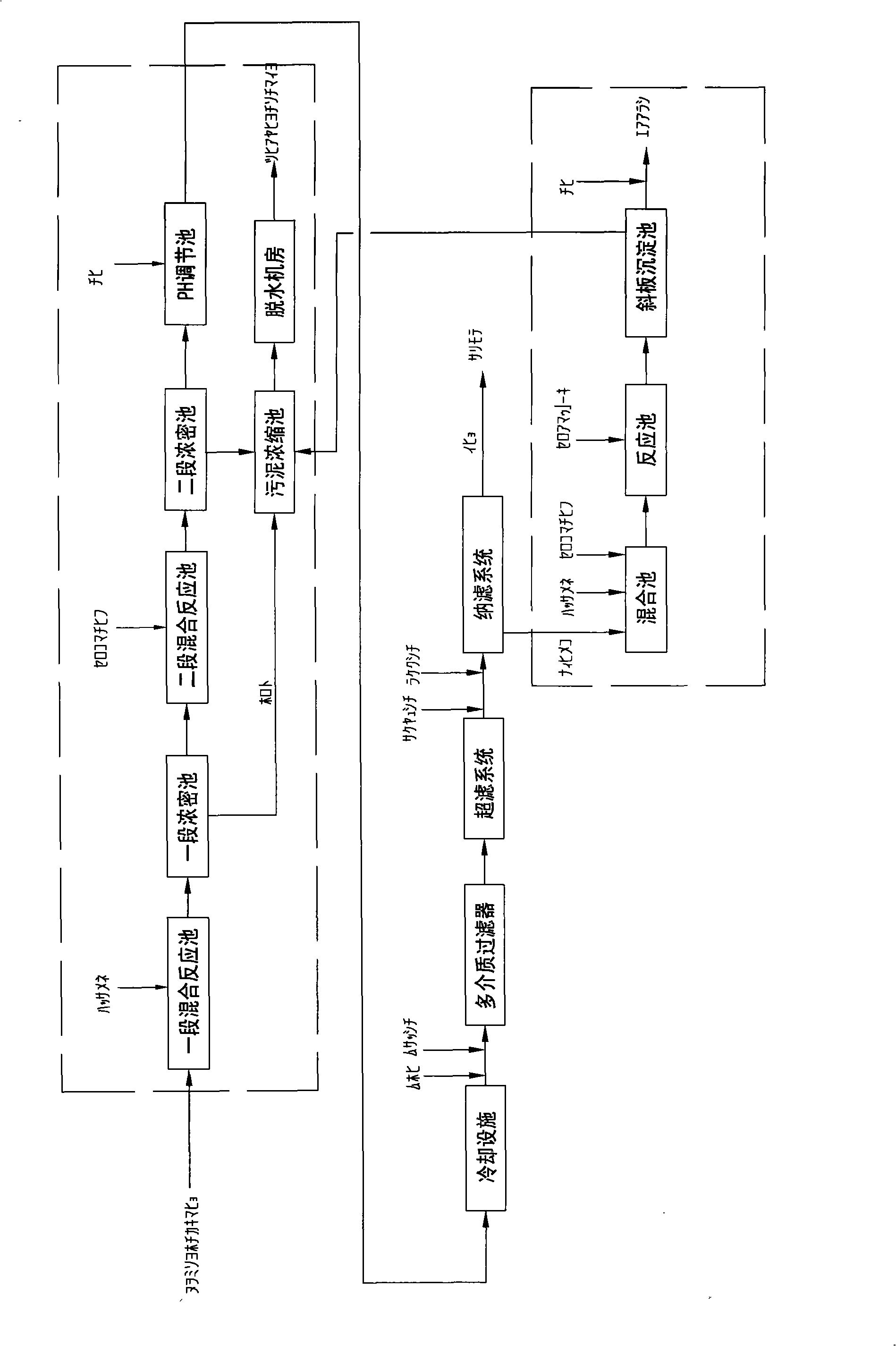

[0007] A membrane separation process for lead-zinc smelting wastewater. This process is aimed at the current situation that most of the industrial wastewater of major domestic lead-zinc smelting enterprises is treated by heavy metal precipitation process and discharged out after reaching the standard. The reuse rate is low and the water quality is poor. For engineering application and promotion, the membrane process adopts the pretreatment method of "heavy metal precipitation process + cooling system + multi-media filter + ultrafiltration", and the main process adopts "nanofiltration" process.

[0008] See accompanying drawing 1, the specific implementation mode is as follows according to technological process:

[0009] Lead-zinc smelting wastewater is firstly treated by heavy metal precipitation process to meet the standard: the wastewater first enters a mixed reaction tank, and the pH of the wastewater is adjusted to 10.5-11 by adding lime milk, and the heavy metals (mainly C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com