Automatic control method for prestressed intelligent tensioning

An intelligent tensioning and prestressing technology, which is applied in the direction of erecting/assembling bridges, bridge materials, bridges, etc., can solve the problems of prestressed tendons breaking, meeting design requirements, and uncertain stress loss, so as to maintain stability, Avoid interference and dislocation effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0065] The present invention will be further described below in conjunction with the embodiments and accompanying drawings.

[0066] A prestressed intelligent tensioning automatic control method, comprising: a step for installing a tensioning device;

[0067] A step for the tensioning device to perform tensioning construction on the prestressed tendons; a step for the tensioning device to perform locking construction on the prestressed tendons; a step for the controller f to perform intelligent control of the tensioning construction.

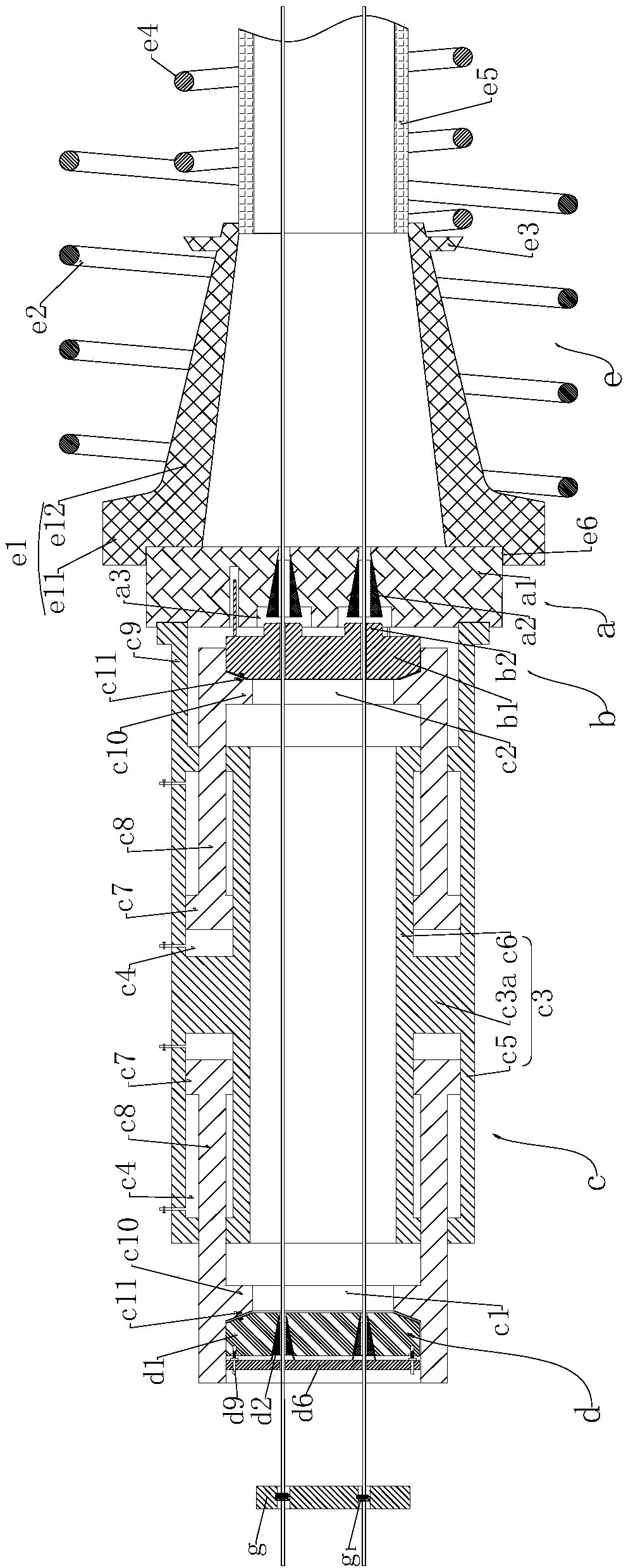

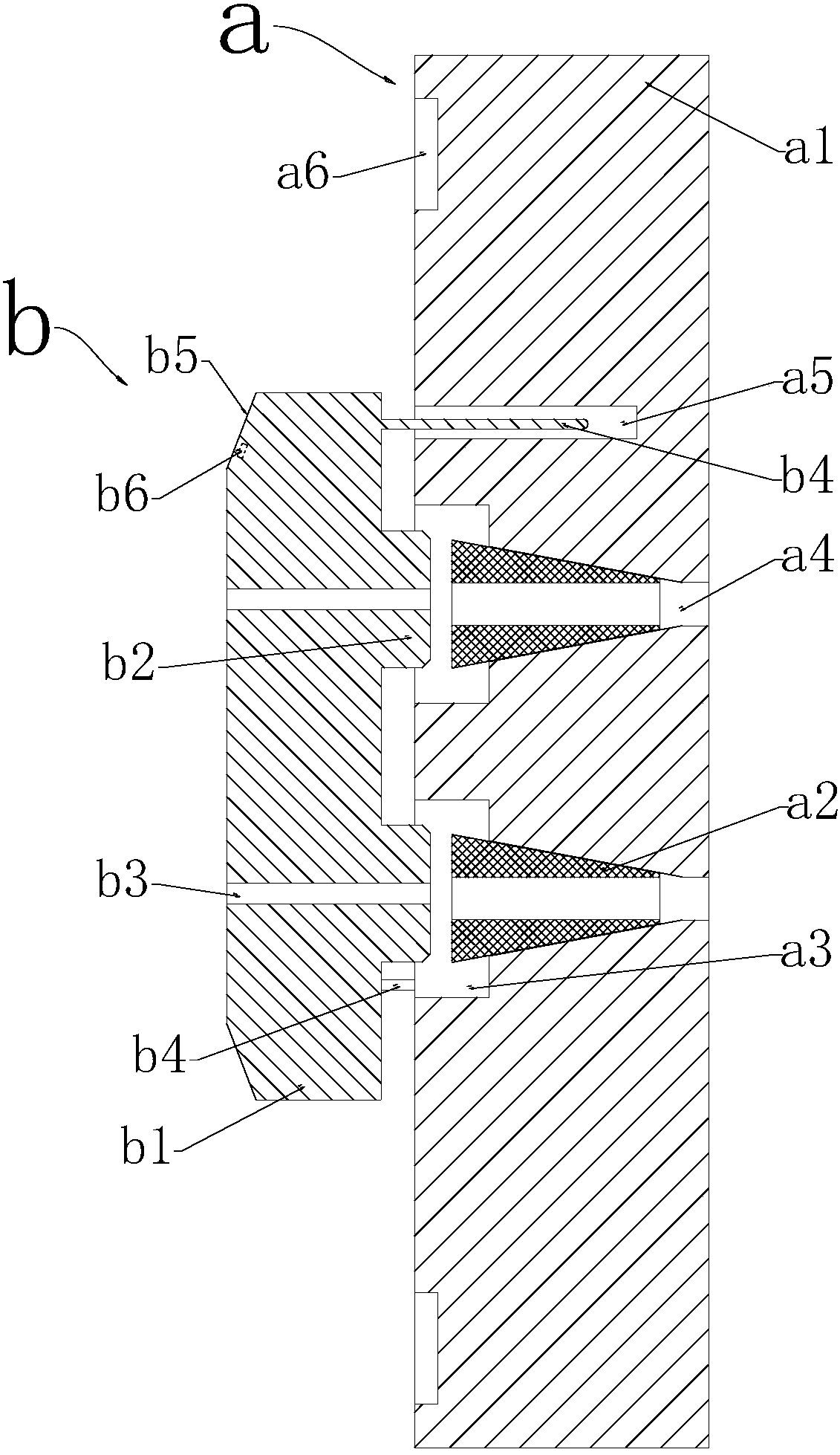

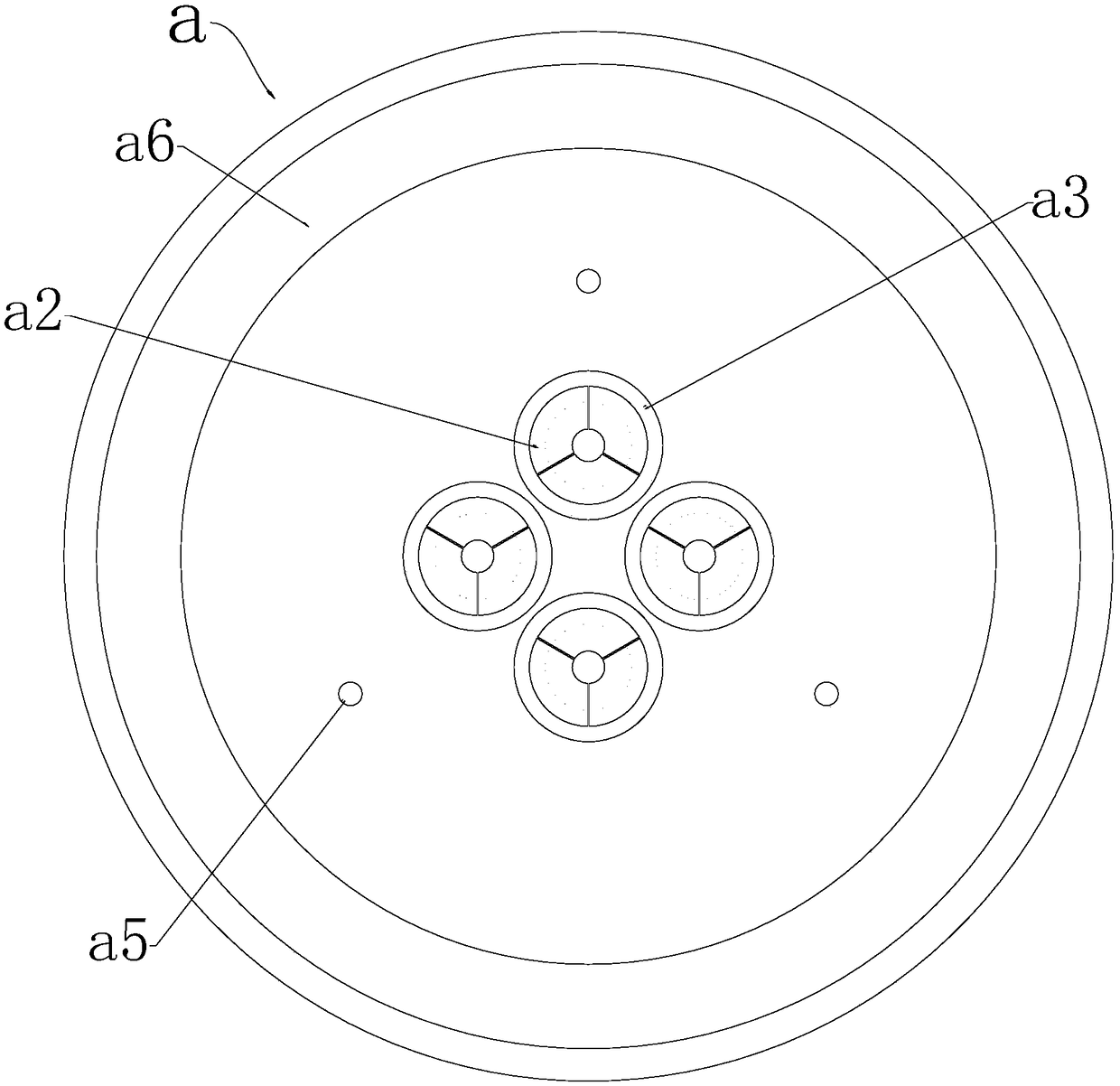

[0068] combine figure 1 It can be seen that in this embodiment, the tensioning device includes an anchor plate assembly e, a working anchor assembly a, a reverse compression plate b, a jack c, and a tool anchor assembly d; it also includes at least one prestressed tendon, The anchor plate assembly e, the working anchor assembly a, the reverse compression plate b, the jack c and the tool anchor assembly d sequentially abut against and sleeve on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com