Manufacturing method for prestress small box girder

A manufacturing method and technology of small box girder, applied in bridges, bridge materials, bridge construction and other directions, can solve the problems of poor grouting of ducts, affecting the quality of beams, large tension at the ends of prestressed tendons, etc., so as to improve the utilization rate. , The effect of reducing tension and stress loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below by non-limiting embodiment:

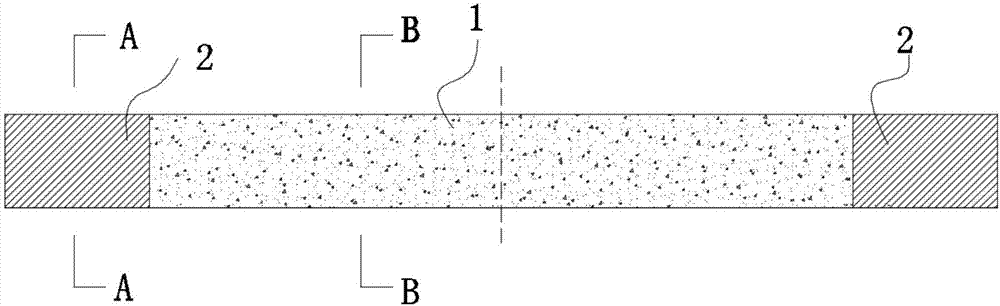

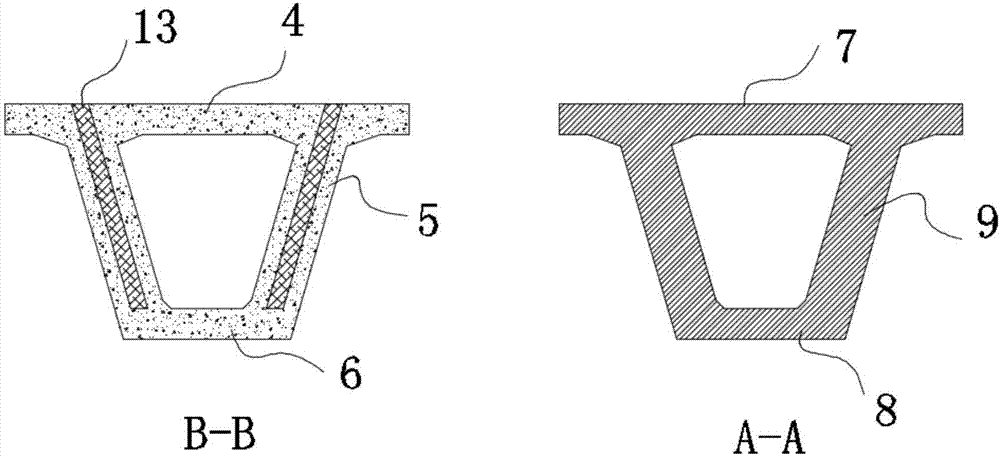

[0035] A method for manufacturing prestressed small box girders, such as figure 1 As shown, the prestressed small box girder is divided into the middle open channel section 1 and the anchor section 2 located at both ends of the open channel section 1, and the whole prestressed small box girder is poured in three times, as follows:

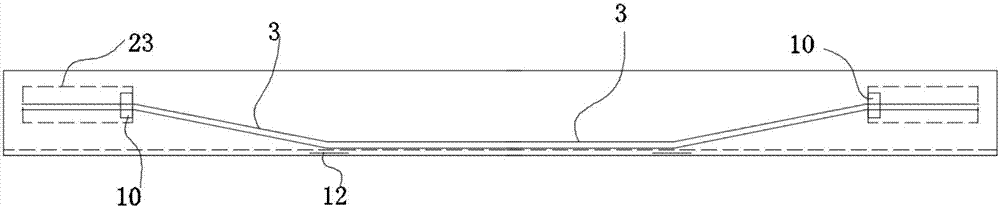

[0036] Step 1. First pour the open channel section 1, reserve the open channel 13 for arranging the prestressed ribs 3 on the prestressed small box girder web of the open channel section 1, and preset two holes at the bottom of the open channel 13 at a distance. A tension hole 14 for tensioning the prestressed tendons 3;

[0037] Step 2, thread the prestressed tendons 3 in the open groove 13 reserved in the open groove section 1, connect the threaded prestressed tendons 3 with the reinforcement cages of the anchorage sections 2 at both ends, and pour the anc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com