Concrete bearing device and testing method thereof

A concrete test piece and concrete technology, applied in the direction of measuring devices, using stable tension/pressure testing material strength, instruments, etc., can solve problems such as the inability to guarantee the normal operation of force-transmitting objects, difficulties in the assembly process, and difficulties in tightening bolts. Achieve low loss of compressive stress, easy assembly and disassembly, and small stress loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Below in conjunction with accompanying drawing and embodiment the present invention is further described:

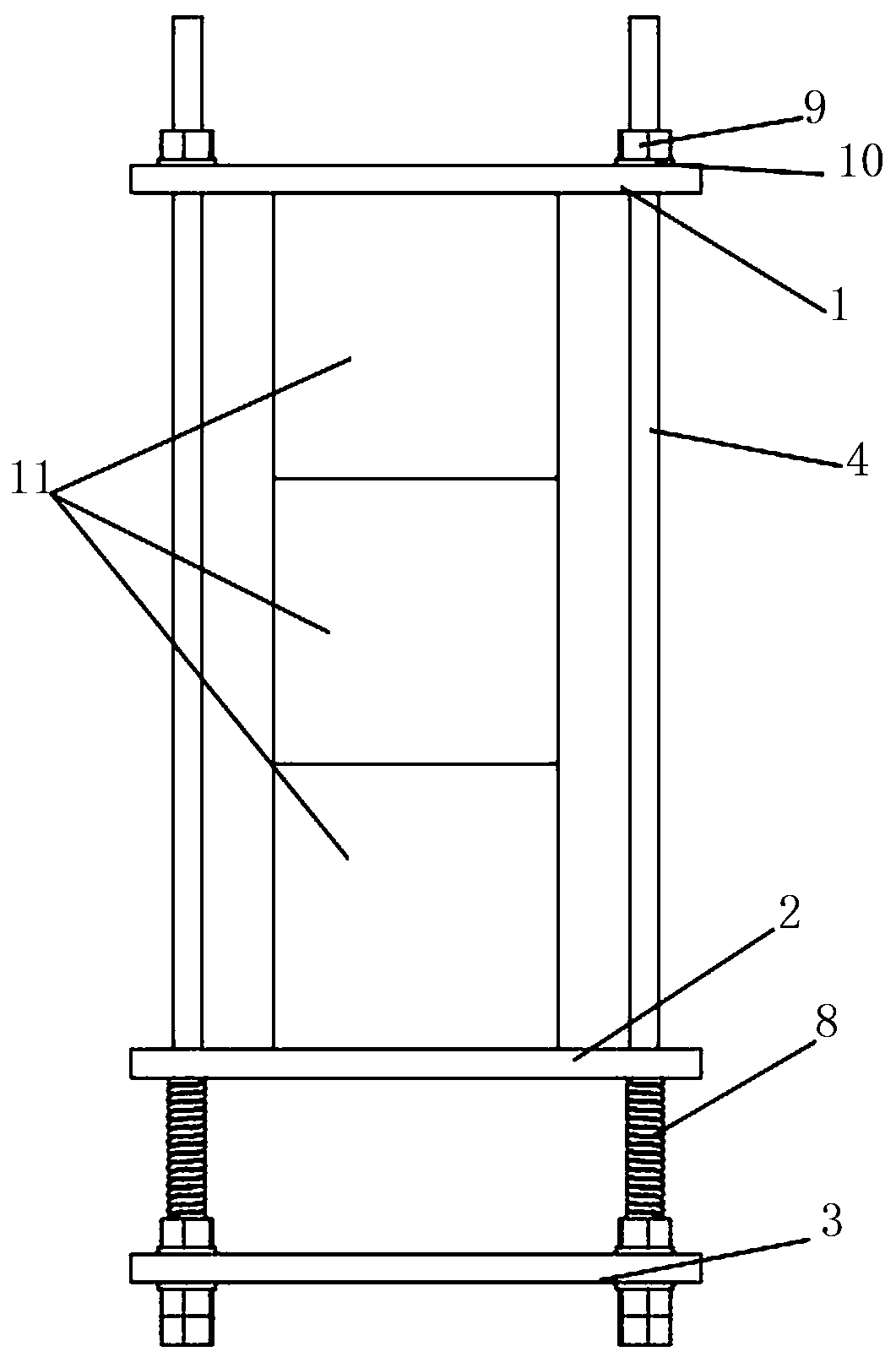

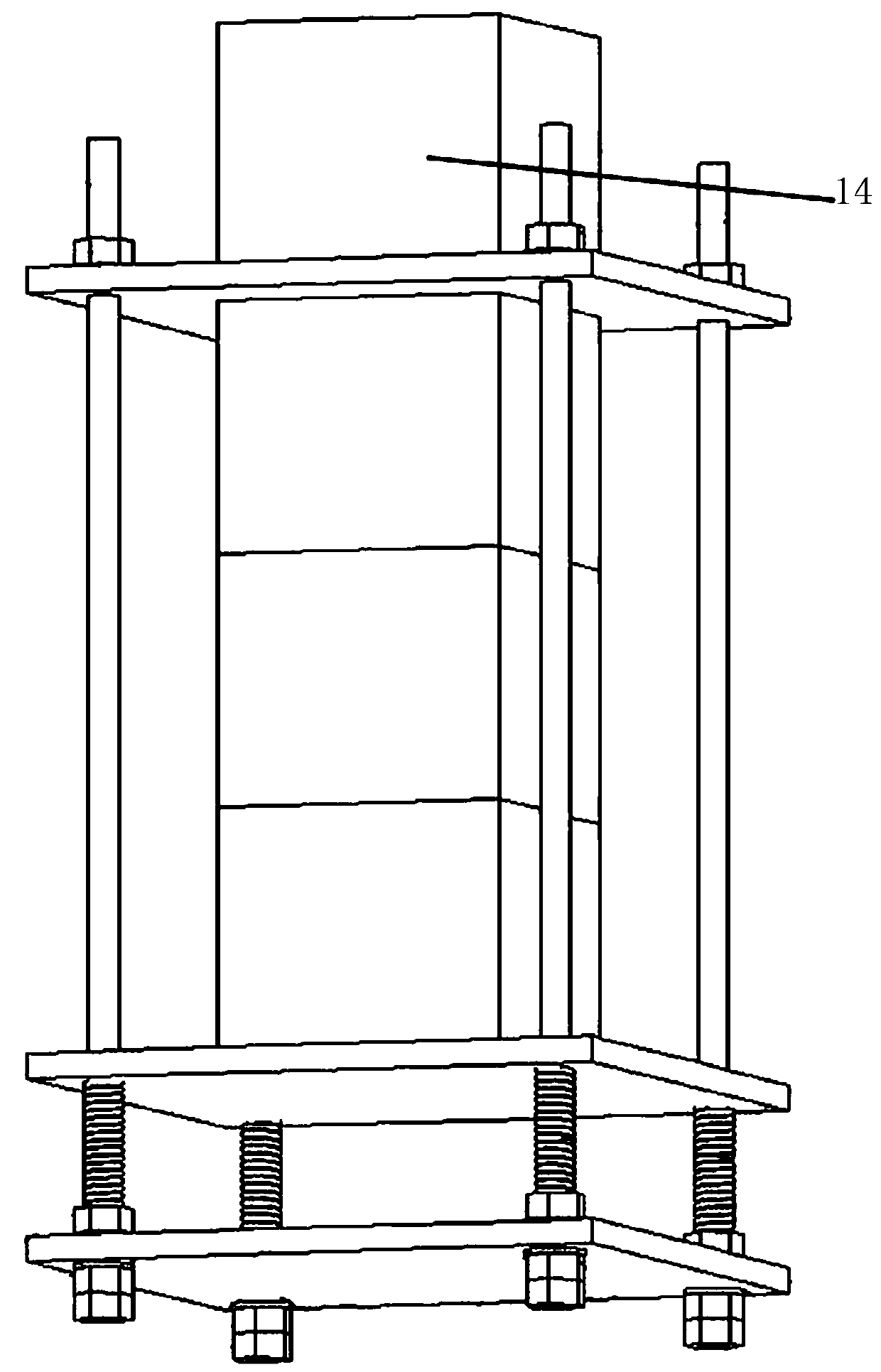

[0030] see Figure 1-2 .

[0031] The invention discloses a concrete carrying device, which comprises an upper bearing plate 1, a lower bearing plate 2, and screw rods 4 evenly distributed on the edges of the upper bearing plate 1 and the lower bearing plate 2, and each of the screw rods 4 passes through the upper bearing plate in turn. The plate 1 and the lower bearing plate 2 can move relatively. The lower end of the lower bearing plate 2 is also provided with a base plate 3. The screw 4 passes through the upper bearing plate 1, the lower bearing plate 2 and the base plate 3 in turn. The lower end of the screw 4 Fixed with the base plate 3, an elastic device is arranged between the lower load plate 2 and the base plate 3, a plurality of concrete specimens 11 are vertically stacked between the upper load plate 1 and the lower load plate 2 and the top concrete te...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com