Irradiation-resistant erbium-doped optical fiber for space and preparation method of irradiation-resistant erbium-doped optical fiber

An erbium-doped optical fiber, radiation-resistant technology, applied in cladding optical fiber, laser, optical waveguide light guide, etc., can solve problems such as failure and optical fiber performance degradation, and achieve the effect of reducing loss, reducing stress loss, and suppressing easy dehydrogenation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

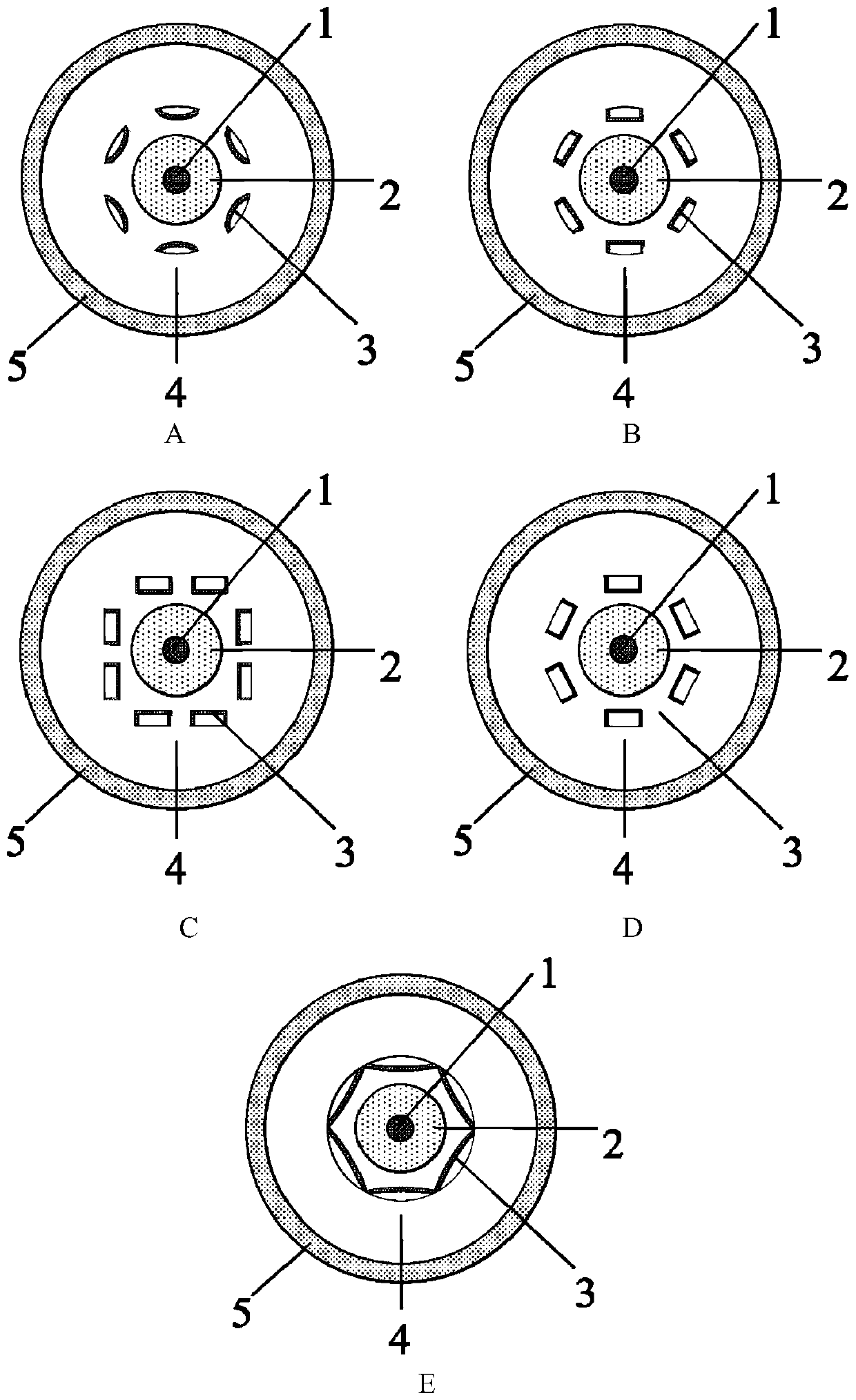

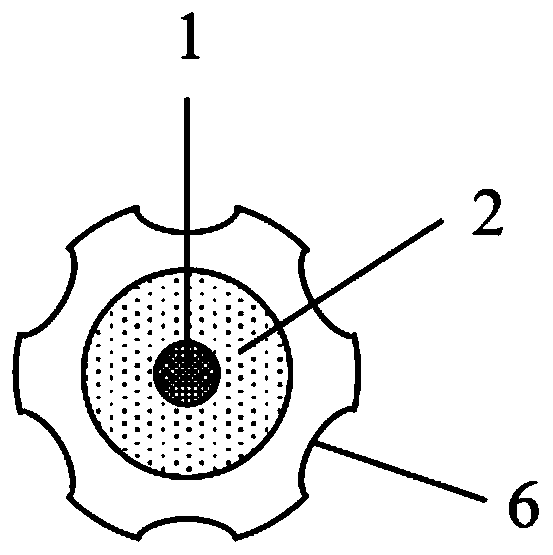

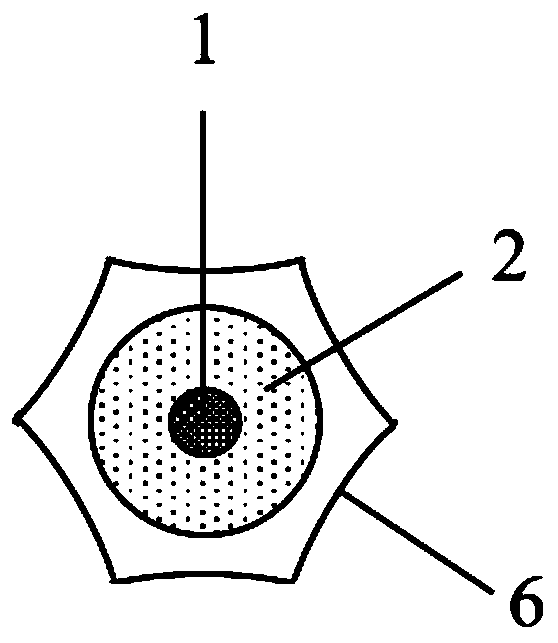

Embodiment 1

[0045] The erbium-doped optical fiber core rod is prepared by MCVD combined with chelate vapor deposition method. Firstly, the quartz deposition tube is preheated, oxidized and impurity-removed and eroded sequentially; Reaction material SiCl 4 、Er(TMHD) 3 , AlCl 3 、GeCl 4 The flow rate, as shown in Table 2, starts to deposit the core layer in the tube, the deposition temperature is 1895 ° C, and the rotation speed is 30 rpm / min; after the deposition is completed, 5 sccm of Cl 2 The quartz tube is collapsed into a solid rod. Secondly, the Au film is coated on the surface of the mandrel by magnetron sputtering, and then the surrounding groove is machined longitudinally along the surface of the mandrel, such as figure 2 shown; then the mandrel was put into a special tubular resistance furnace, and the carbon nanotube layer was prepared by chemical vapor deposition in situ growth method, with ferrocene as catalyst and xylene as carbon source, and ferrocene was dissolved in xy...

Embodiment 2

[0047] The preparation method of the erbium-doped optical fiber core rod and the setting of the reaction materials when depositing the fiber core and the transition layer are the same as in the first embodiment, as shown in Table 2. After the surface of the mandrel is coated with Au film, the surrounding groove is machined longitudinally along the surface of the mandrel, such as image 3 Shown; The method for preparing the carbon nanotube layer on the mandrel groove is as embodiment one, and the difference is that the growth time is 60min, and the rotating speed is 40rpm / min; after growing the carbon nanotube layer, remove the Au outside the mandrel groove film, and then carry out hydroxylation treatment on the carbon nanotube layer on the mandrel groove, the method is as in Example 1. Finally, according to the geometric parameters of the optical fiber, the appropriate sleeve process is selected to meet the requirements of the core-to-clad ratio of the optical fiber, and the f...

Embodiment 3

[0051] The preparation method of the erbium-doped optical fiber core rod, the shape of the surrounding groove, the preparation process of the carbon nanotube layer and the hydroxylation treatment process are the same as in Example 1, except that the reaction materials are set as shown in Table 3 when depositing the fiber core and the transition layer. Show. After the optical fiber preform is made, select the appropriate sleeve process according to the geometric parameters of the optical fiber to meet the requirements of the core-to-clad ratio of the optical fiber, and draw it at a temperature of 2050 ° C to obtain an erbium-doped optical fiber with a specification of 3.2 / 125 μm, and then The optical fiber is treated under the condition of a hydrogen atmosphere with a temperature of 70-75° C. and a pressure of 5-10 MPa for 20-40 hours.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com