Sliding component of compressor, sliding component base, scroll component, and compressor

A technology of sliding parts and compressors, which is applied to machines/engines, parts of pumping devices for elastic fluids, pump parts of rotary piston type/oscillating piston type, etc. , decline and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

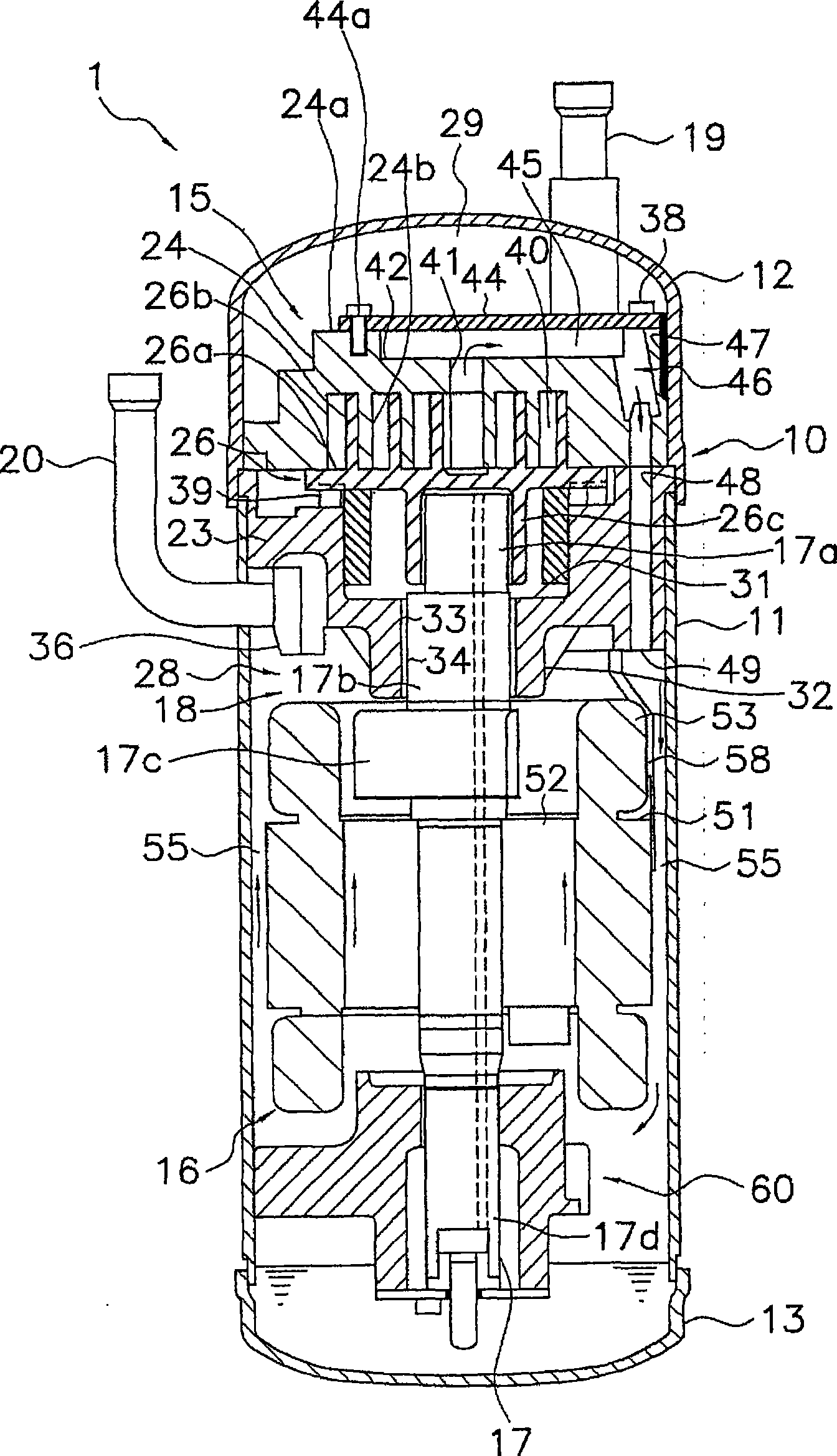

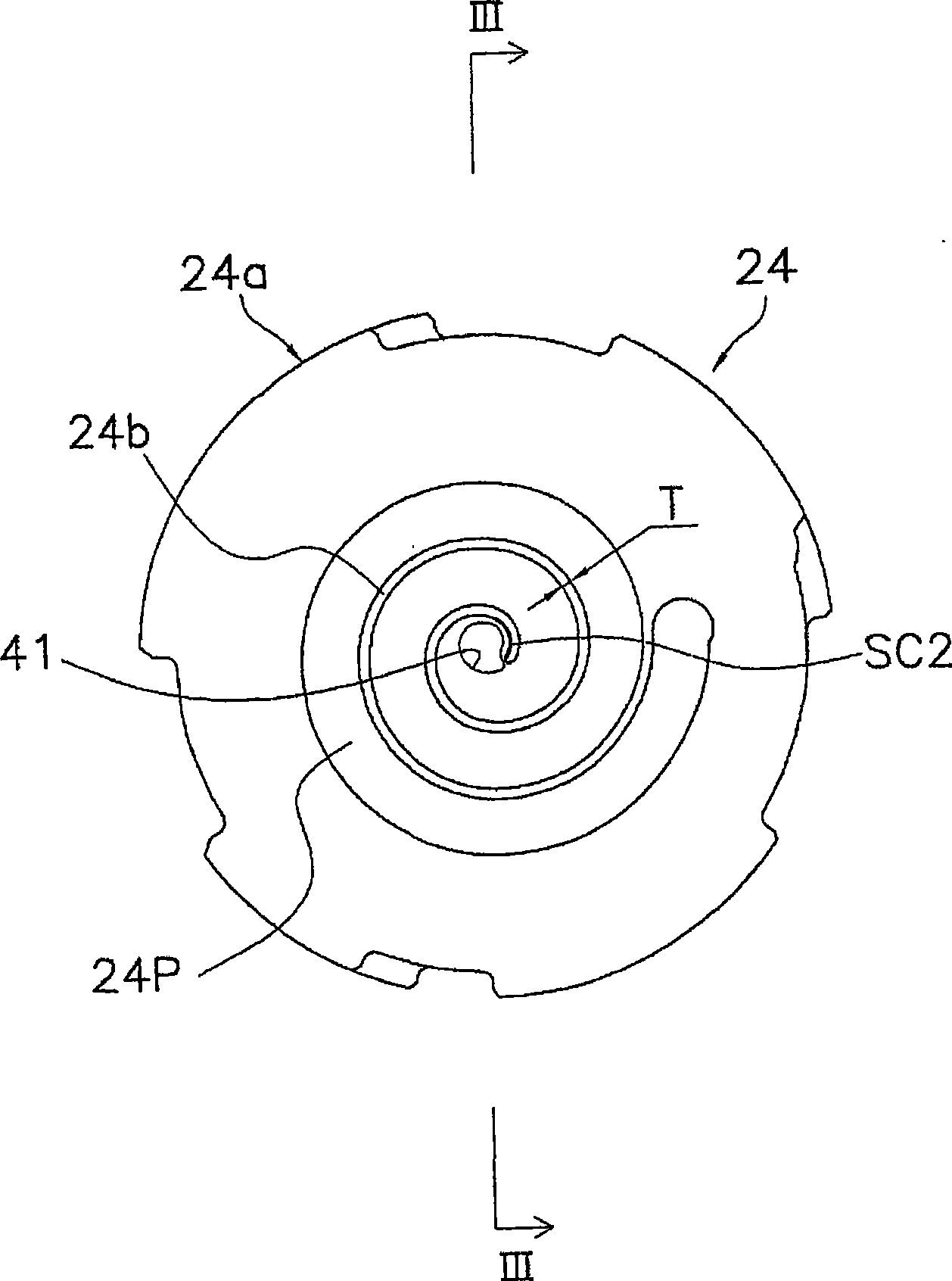

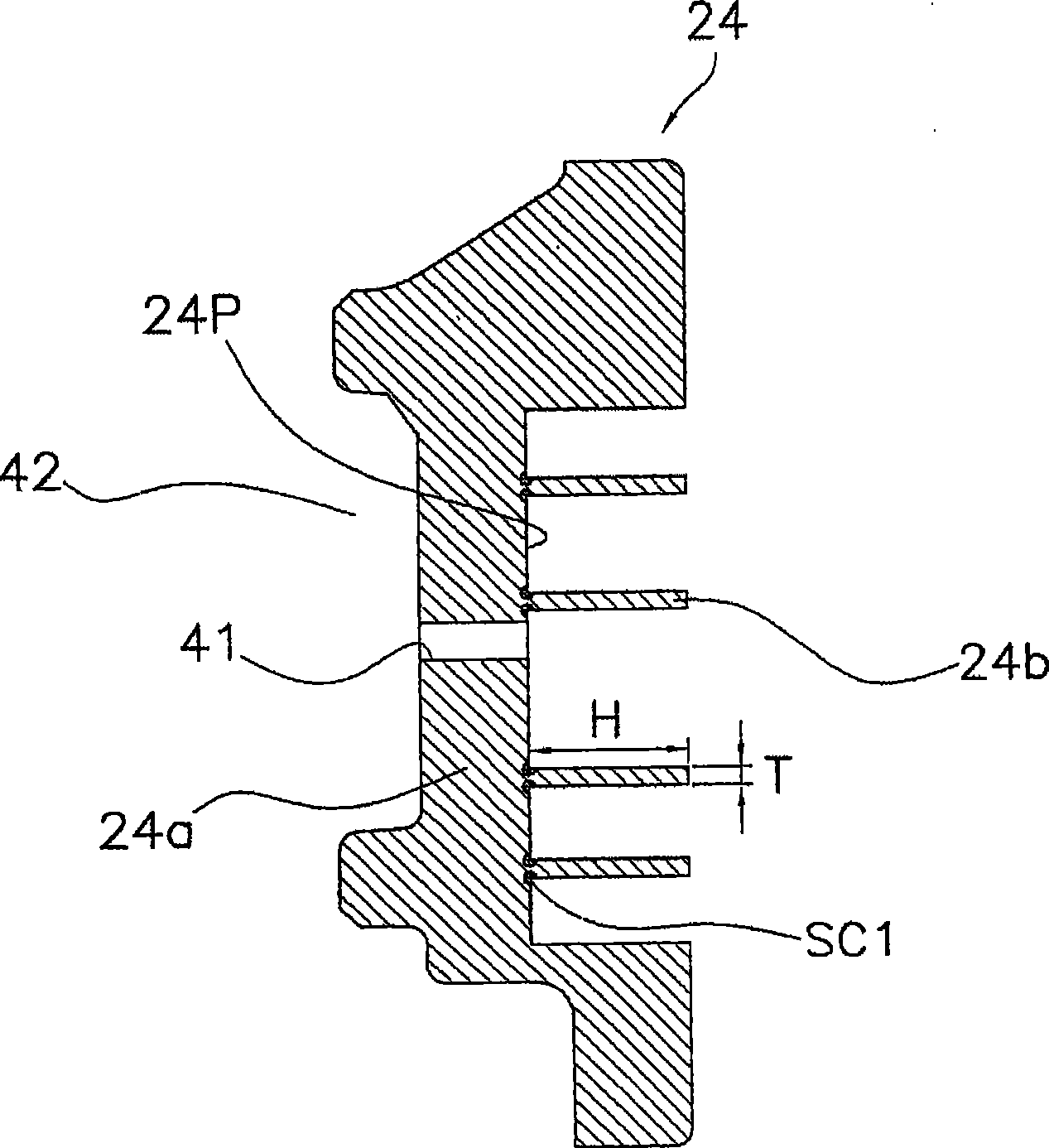

[0188] Hereinafter, a high-low pressure dome-type scroll compressor will be described as an example of a compressor employing the sliding member according to the first embodiment. In addition, the high-low pressure dome-type scroll compressor described in the first embodiment is designed to cope with carbon dioxide refrigerant (CO 2 ) or high-pressure refrigerants such as R410A.

[0189] The high-low pressure dome-type scroll compressor 1 described in the first embodiment comprises a refrigerant circuit composed of an evaporator, a condenser, an expansion mechanism, etc., and performs the function of compressing the gas refrigerant in the refrigerant circuit. ,Such as figure 1 As shown, the high and low pressure dome type scroll compressor 1 is mainly composed of the following parts: a cylindrical sealed dome type housing 10, a scroll compression mechanism 15, an Oldham slip ring 39, a driving motor 16, a lower part Main bearing 60 , suction pipe 19 and discharge pipe 20 . ...

no. 2 approach

[0369] Hereinafter, a high-low pressure dome-type scroll compressor will be described as an example of a compressor using the sliding member according to the second embodiment. In addition, the high-low pressure dome-type scroll compressor described in the second embodiment is replaced by the outer drive type movable scroll 26 of the high-low pressure dome-type scroll compressor 1 described in the first embodiment. It is obtained by forming an internally driven movable scroll. Therefore, only the movable scroll will be described below.

[0370] [Structure of the movable scroll]

[0371] Such as Figure 33 As shown, the movable scroll 96 is mainly composed of the following parts: a mirror plate 96a; a spiral (involute) scroll tooth 96b extending upward from a mirror surface 96P of the mirror plate 96a; a bearing portion 96c, which extending downward from the lower surface of the mirror plate 96a; and groove portions 96d formed at both ends of the mirror plate 96a.

[0372] ...

no. 3 approach

[0386] Hereinafter, a high-low pressure dome-type scroll compressor will be described as an example of a compressor using the sliding member according to the third embodiment. In addition, the difference between the high and low pressure dome scroll compressor 1 described in the third embodiment and the high and low pressure dome scroll compressor 1 described in the first embodiment is only the fixed scroll and the movable scroll The spiral tooth shape of the turntable. Therefore, only the fixed scroll and the movable scroll will be described below.

[0387] The base 626 of the movable scroll 526 described in the third embodiment uses, for example, Figure 35 The metal mold 180 shown is formed by semi-molten die casting.

[0388] Specifically, as follows.

[0389] Such as Figure 35 As shown, a metal mold 180 is used to form the base body 626 of the orbiting scroll 526 by semi-molten die casting, and the metal mold 180 is composed of a first mold portion 181 and a second m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Young's modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com