Continuous coating production system of sheet substrates

A production system and technology for substrates, which are applied in sputtering coating, ion implantation coating, vacuum evaporation coating and other directions, can solve the problems of stress loss of tempered glass base, unattainable and decreased strength of thermochromic smart glass, etc. To achieve the effect of reducing stress loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

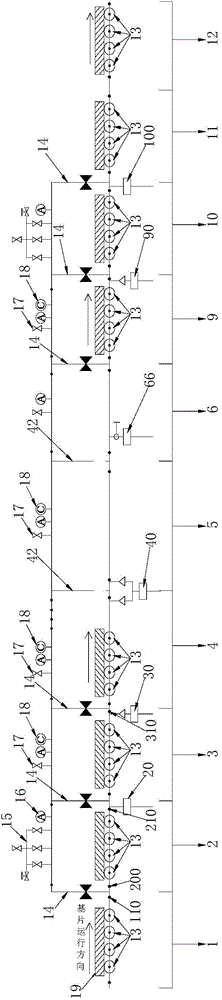

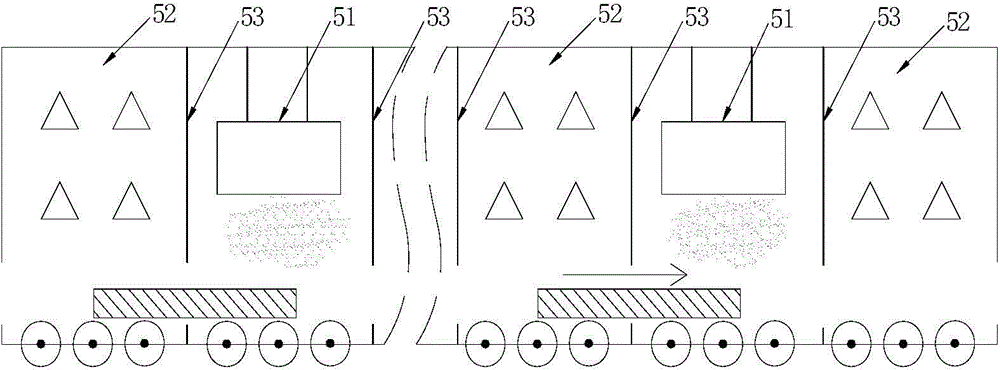

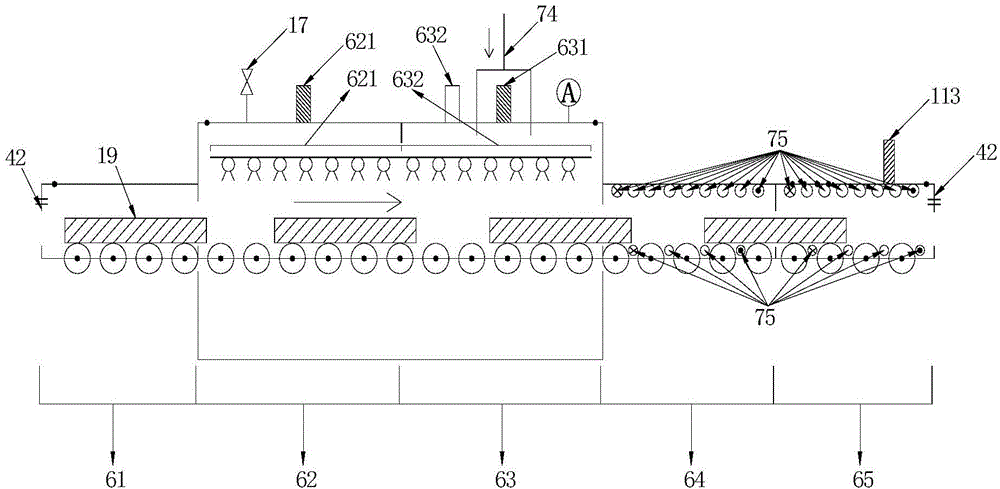

[0054] Taking tempered glass-based thermochromatic intelligent glass coating production as an example, such as figure 1 The continuous coating system shown includes a film feeding platform 1 , a working area and an unloading platform 12 . The working area is equipped with various functional rooms for coating and annealing operations, including the first coating deposition room 5, the rapid atmosphere annealing room 6 and the air grid quenching area 11. Five vacuum chambers are also installed in the working area, namely the first vacuum chamber 2 , the second vacuum chamber 3 , the first transition chamber 4 , the third vacuum chamber 9 and the fourth vacuum chamber 10 . Each functional room is according to the film feeding table 1-first vacuum chamber 2-second vacuum chamber 3-first transition chamber 4-coating deposition chamber 5-rapid atmosphere annealing chamber 6-third vacuum chamber 9-fourth vacuum chamber 10- The sequence of air grid quenching zone 11-unloading platfor...

Embodiment 2

[0082] The difference between this embodiment 2 and embodiment 1 is that, in addition to a first coating deposition chamber 5 connected upstream of the rapid atmosphere annealing chamber 6, a second coating deposition chamber 7 is also connected downstream of the rapid atmosphere annealing chamber 6 . A second transition chamber 8 is connected downstream of the second coating deposition chamber 7 . The second coating deposition chamber 7 and the second transition chamber 8 are connected with a fifth vacuum pump group 78 . After the substrate is removed from the rapid atmosphere annealing chamber 6, it will enter the second coating deposition chamber 7 located downstream of the rapid atmosphere annealing chamber 6 for the second coating treatment, thereby depositing a multilayer composite film on the upper surface of the glass substrate. The glass substrate that moves out from the second coating deposition chamber 7 subsequently enters the second transition chamber 8 positione...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com