Adjustable automatic load shedding sound barrier

A sound barrier and adjustable technology, applied in construction, noise absorption devices, etc., can solve problems such as cracking, air turbulence, loose concrete, etc., and achieve the effects of reducing wind load, improving work efficiency, and saving costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

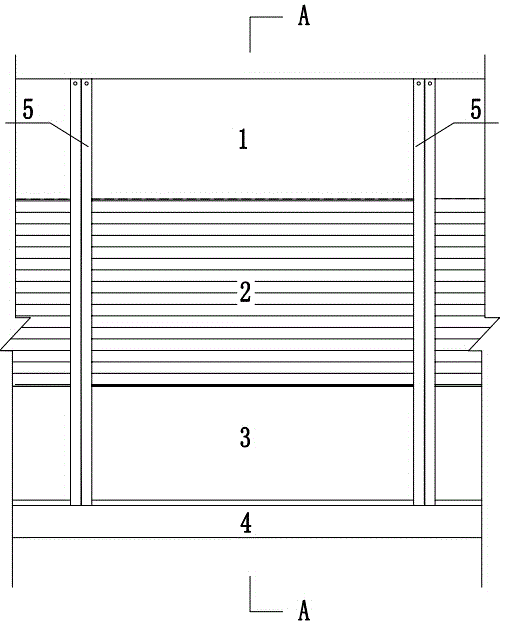

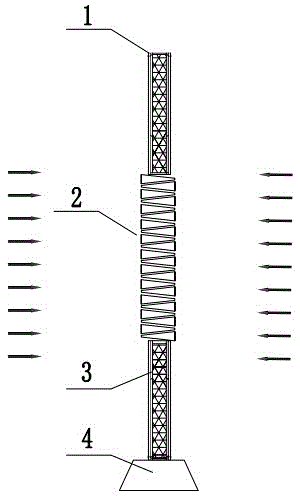

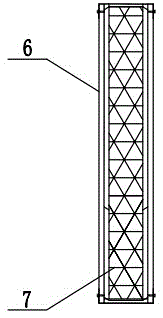

[0021] An adjustable automatic load-reducing sound barrier, the load-reducing sound barrier includes: an upper plate 1 , a middle plate 2 , a lower plate 3 , a base 4 and a column 5 . The base 4 is a concrete structure, fixed on the outermost deck of the high-speed railway bridge, two columns 5 are fixed on the base 4 by anchor bolts, and the upper plate 1, middle plate 2 and lower plate 3 are respectively fixed from top to bottom Between the two columns 5, the upper board 1 and the lower board 3 are composed of inner and outer layers, the outer layer 6 is sound-absorbing material, the inner layer 7 is the sound barrier plastic-steel inner frame, the fixing of the upper board 1 and the lower board 3 Angle steel with bolt holes and bolts can be used to connect the inner layer 7 and the column 5; the middle plate 2 includes a plurality of long sound insulation panels 9 arranged alternately from top to bottom, and the sound insulation panels 9 are fixed on the two columns 5 by bol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com