Brightening and noise-reducing composite ceramic tile and preparation method thereof

A ceramic tile and noise reduction technology, which is applied in covering/lining, construction, reflection/signal coatings, etc., can solve the problems of difficulty in meeting the requirements of outdoor independent use, increasing the production cost of noise reduction barriers, and not being able to play auxiliary brightening, etc., to achieve good results Acid and alkali corrosion resistance, energy consumption reduction, and convenient application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0053] The present invention provides a method for preparing the brightening and noise-reducing composite tile described in the above scheme, comprising the following steps:

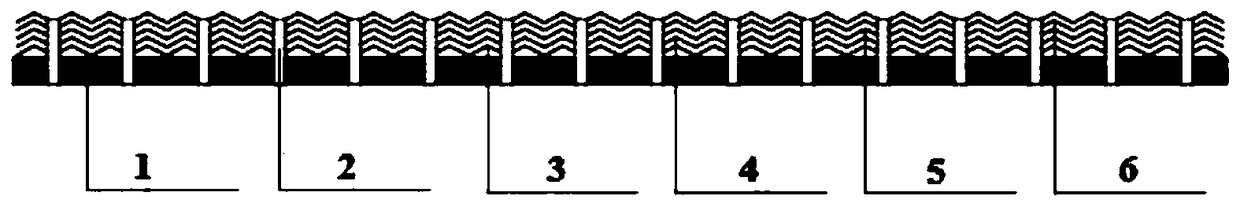

[0054] Press the upper surface of the substrate to form a concave-convex texture structure;

[0055] Mix the raw materials of the reflective material layer and apply it on the surface of the substrate to form a reflective material layer on the surface of the substrate;

[0056] Mixing the raw materials of the protective layer and coating it on the surface of the reflective material layer to form a composite tile precursor;

[0057] A mold is used to press the composite tile precursor to form a tapered through hole running through the thickness direction of the composite tile precursor to obtain a brightness-enhancing and noise-reducing composite tile.

[0058] The invention presses the upper surface of the substrate to form a concave-convex texture structure on the surface of the substrate. In the pres...

Embodiment 1

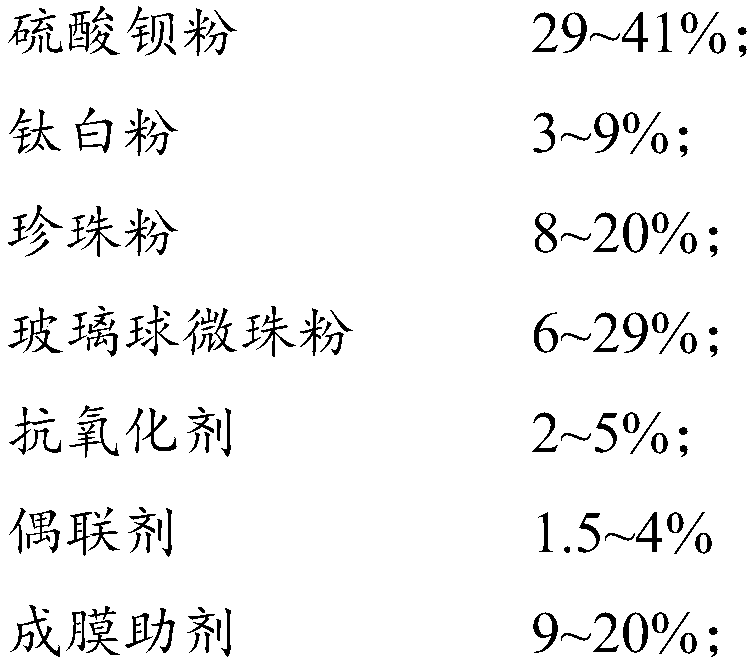

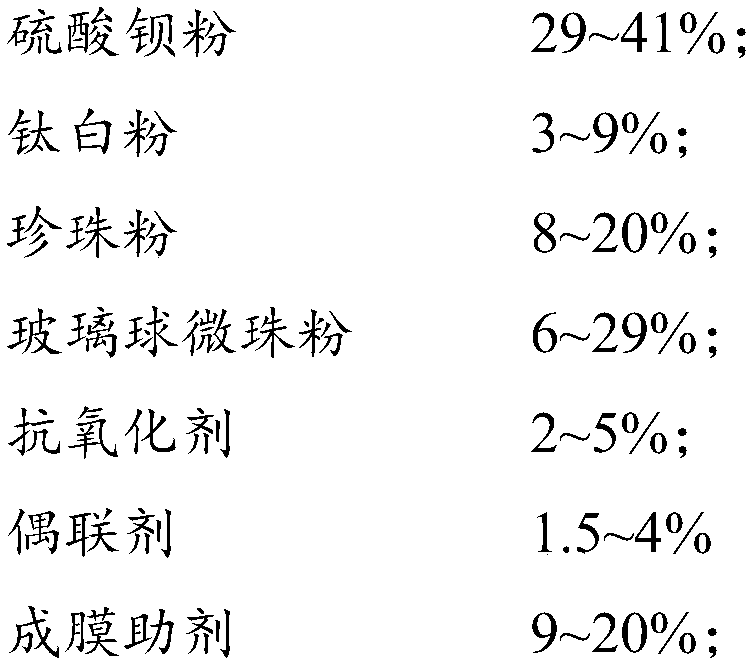

[0070] Reflective material layer component: barium sulfate powder 35wt%, titanium dioxide 9wt%, pearl powder 15wt%, glass ball microbead powder 20wt%, antioxidant (antioxidant DNP) 2wt%, film-forming aid (alcohol ester twelve ) 10wt%, coupling agent 1.5%, the organic solvent (ethanol) of remainder;

[0071] Protective layer components: phthalate 0.1wt%, titanium dioxide 1wt%, silicon dioxide 1wt%, methyl acrylate 10wt%, antioxidant 1010.5wt%, alcohol ester twelve 8wt%, coupling agent 3wt% , 50 wt% of butyl acrylate, and the balance of water and alcohol solvents.

[0072] Use ceramics as the substrate with a thickness of 5cm. First, carry out mold stamping on the surface of the substrate to form a concave-convex texture structure (the depth of the depression is 3mm, and the height of the protrusion is 3mm), and then mix the raw materials of the reflective material layer and spray it on the surface of the substrate. Curing at ℃ for 10 minutes to form a reflective material layer...

Embodiment 2

[0079] Reflective material layer component: barium sulfate powder 30wt%, titanium dioxide 9wt%, pearl powder 12wt%, glass ball microbead powder 20wt%, antioxidant (antioxidant 101) 2.5wt%, film-forming aid (alcohol ester ten Two) 15wt%, the organic solvent (ethanol) of surplus;

[0080] Protective layer components: phthalate 0.1wt%, titanium dioxide 1wt%, silicon dioxide 1wt%, methyl acrylate 10wt%, antioxidant 1010.5wt%, alcohol ester twelve 8wt%, coupling agent 3wt% , 50 wt% of butyl acrylate, and the balance of water and alcohol solvents.

[0081] Use soft porcelain as the substrate with a thickness of 8cm. Firstly, mold stamping is carried out on the surface of the substrate to form a concave-convex texture structure (the depth of the depression is 3mm, and the height of the protrusion is 3mm). Then, the raw materials of the reflective material layer are mixed and sprayed on the surface of the substrate. Curing at 150°C for 10 minutes to form a reflective material layer o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com