Method for synthesizing bisphenol-F with catalysis of phosphotungstic acid modified short channel HPW-Zr/SBA-15 catalyst

A catalyst and short-channel technology, which is applied in the field of catalytic synthesis of bisphenol F, can solve problems such as unfavorable mass transfer and reaction, difficulty in separation and recovery, and poor thermal stability, so as to improve mass transfer and reaction efficiency, high catalytic activity, and corrosion resistance. small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] (1) Preparation of short-channel HPW-Zr / SBA-15 catalyst modified by phosphotungstic acid

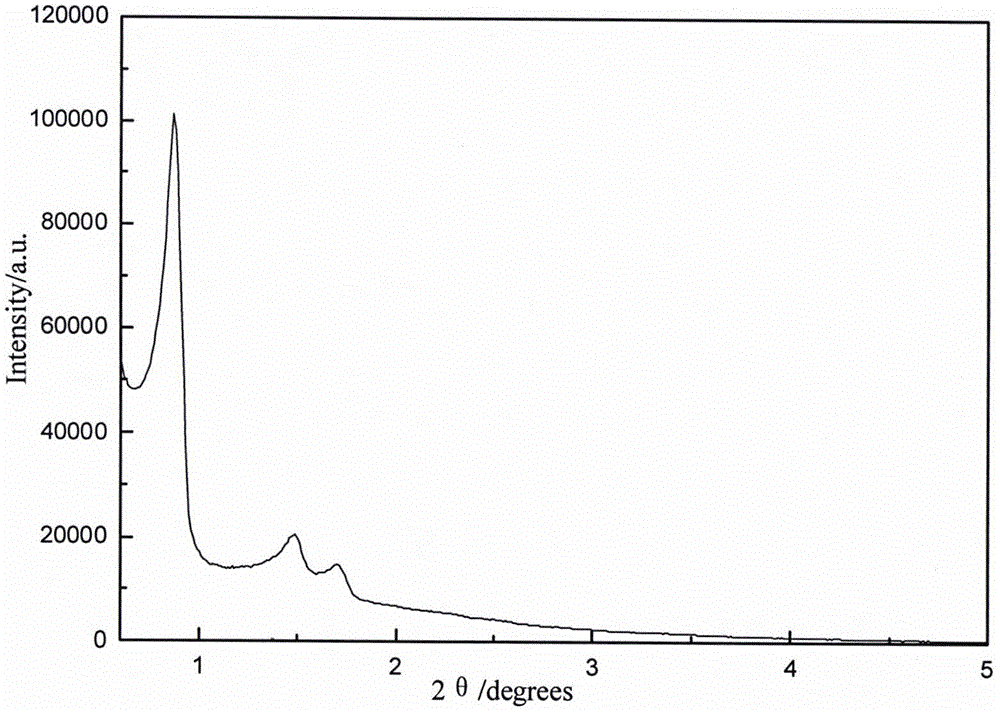

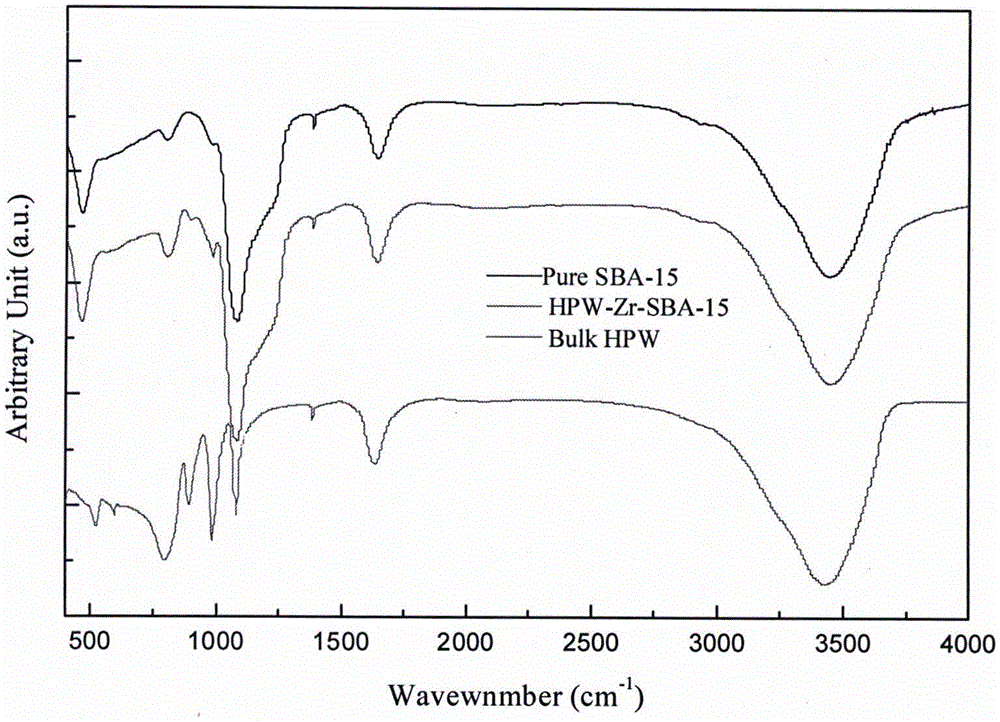

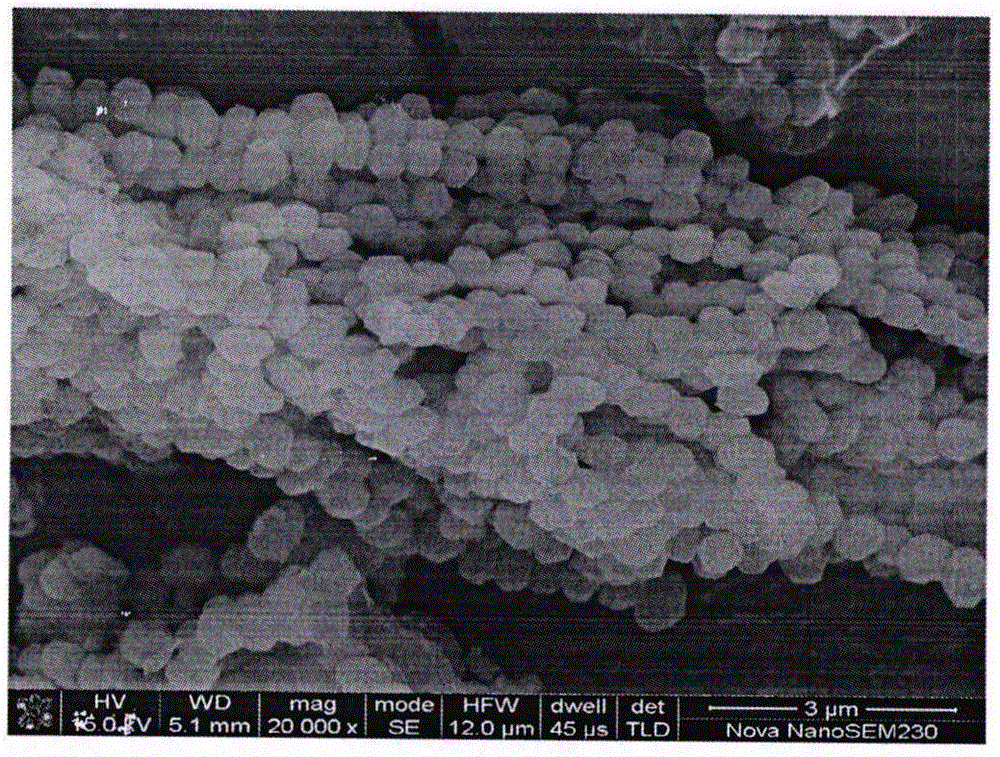

[0028] Using phosphotungstic acid as the active component and zirconium oxychloride as the modifier, a short-channel HPW-Zr / SBA-15 catalyst was synthesized by one-step method: 2g polyethylene oxide-polypropylene oxide-polyethylene oxide three Add the block copolymer (P123) into a 250mL reactor, add 15g of deionized water and 60ml of 2mol / L dilute hydrochloric acid, control the reaction temperature at 40°C, stir evenly at 300rpm, slowly add 3.2g of zirconium oxychloride, stir and dissolve , then add 4.7g ethyl orthosilicate and 10mL aqueous solution dissolved with 0.7g phosphotungstic acid, keep stirring for 24h, then transfer the mixed solution into a polytetrafluoroethylene hydrothermal kettle to crystallize at 100°C for 24h, filter and wash , dried at 80°C for 8h, moved to a muffle furnace, and was calcined at 2°C / min to 550°C for 6h to prepare the short-channel HPW-Zr / SBA-15 ca...

Embodiment 2

[0037] The operation steps are the same as in Example 1, the difference is that the amount of formaldehyde is 3.24g, so that the molar ratio of phenol to formaldehyde is 25:1, the reaction time is 30min, and the yield of bisphenol F is 97.2%.

Embodiment 3

[0039] The operation steps are the same as in Example 1, the difference is that the reaction temperature is 70° C., the reaction time is 5 minutes, and the yield of bisphenol F is 41.66%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com