Method for preparing MFI catalyst carrying transition elements and MFI catalyst application

A transition element and catalyst technology, applied in the preparation of nano-layered MFI catalysts, can solve the problems of large diffusion resistance and low catalytic activity, and achieve the effects of small internal diffusion resistance, improved catalytic activity, and short pores

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

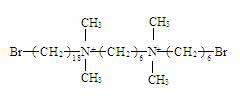

[0033] The object of the present invention is to provide a kind of preparation method of loading transition element MFI catalyst and the application of MFI catalyst thereof, the key of this catalyst synthesis is to develop synthetic gemini cationic surfactant---dibromide-1-(dimethyl Hexylammonium)-6-(dimethyloctadecylammonio)hexane:

[0034]

[0035] As a template agent, with adjustable dynamic rotation synthesis technology, after atom condensation, rearrangement, nucleation, and crystallization, the nucleated atoms are aligned in a plane to form a single-cell nano-layered MFI catalyst support material. The catalytic material modified by transition elements can be used for NO x Selective catalytic reduction, especially for low-temperature NH in diesel vehicle exhaust 3 - SCR catalytic reaction.

[0036] The present invention is characterized in that it effectively overcomes the thermodynamically controlled Ostwald ripening effect in the synthesis system, and the MFI molec...

Embodiment 1

[0045] Water glass (an aqueous solution of sodium silicate, SiO 2 / Na=1.75, 29wt% SiO 2 ), Al 2 (SO 4 ) 3 18. h 2 O, NaOH, C 18-6-6 Br 2 , H 2 SO 4 Mixed with distilled water to obtain a composition of 20Na 2 O:Al 2 o 3 : 69SiO 2 : 10C 18 - 6 - 6 Br 2 : 16H 2 SO 4 : 4,000H 2 O's gel. The resulting gel was transferred to a polytetrafluoroethylene-coated stainless steel autoclave and heated at 150-160°C for 120 hours. The autoclave speed was set at 60-120 r.p.m. After crystallization, the product was filtered. Wash with distilled water and dry at 110-130°C. The product is calcined under flowing air at 450-650°C for 4-6 hours to obtain a single cell nano-layer MFI catalytic material with mesopore and micropore scale thickness of only 2-5 nanometers.

Embodiment 2

[0047] Water glass, Al 2 (SO 4 ) 3 18. h 2 O, NaOH, C 18-6-6 Br 2 , H 2 SO 4 Mixing with distilled water gives a composition of 25Na 2 O:Al 2 o 3 : 80SiO 2 : 10C 18 - 6 - 6 Br 2 :36H 2 SO 4 : 4,000H 2 O's gel. The resulting gel was transferred to a Teflon-coated stainless steel autoclave and heated at 150-160°C for five days with the autoclave speed set at 60-120 r.p.m. After crystallization, the product was filtered and Wash with distilled water and dry at 110-130°C. Calcining the product under flowing air at 450-650°C for 4-6 hours can also obtain a single-cell nano-layer MFI catalytic material with a mesopore and micropore scale and a thickness of only 2-5 nanometers.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com