Method for producing propene for C4 and more olefin catalytic cracking

A catalytic cracking and olefin technology, applied in hydrocarbon cracking, chemical recovery, organic chemistry, etc., can solve the problems of untested catalyst stability and low silicon and aluminum

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~3

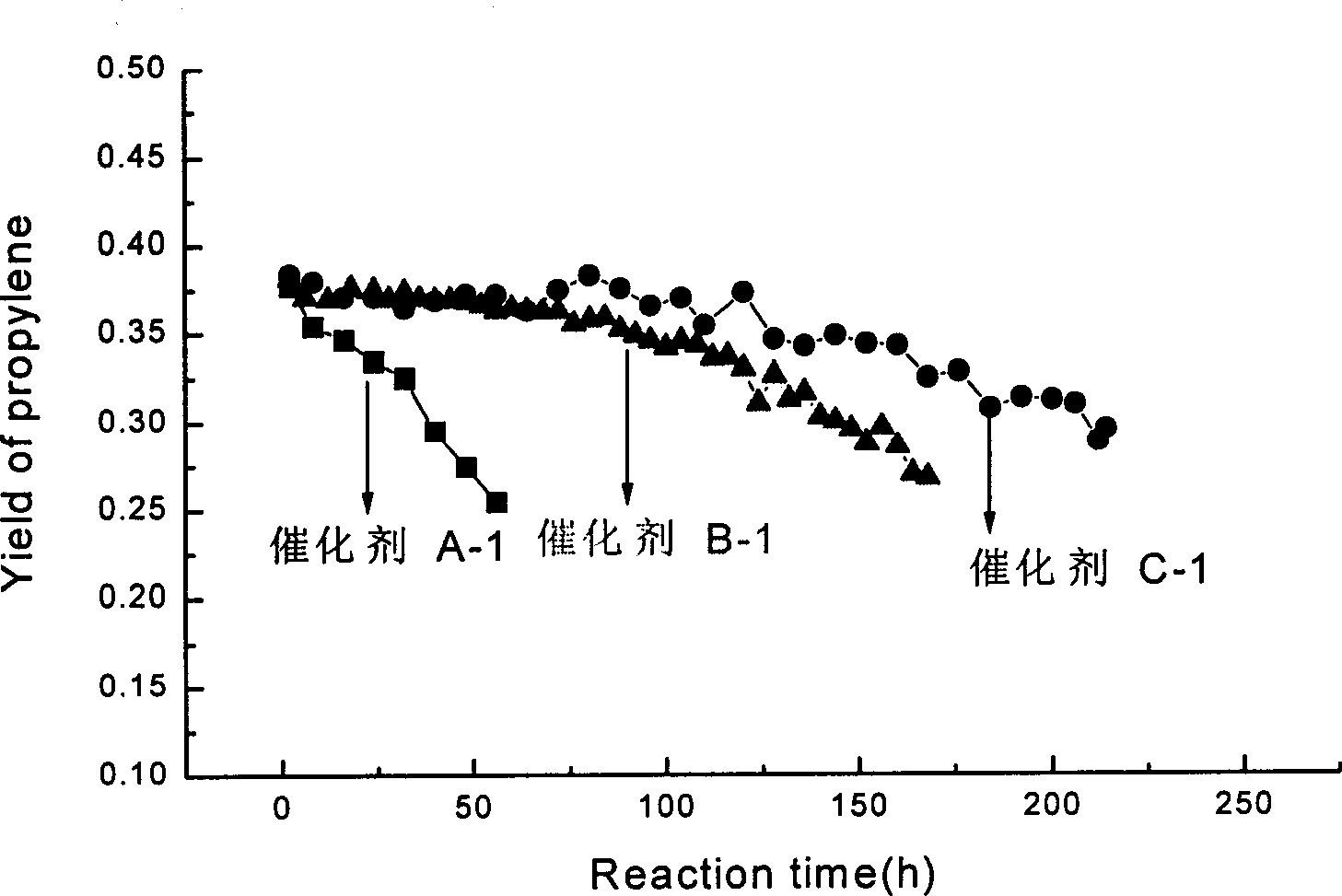

[0018] The size of the molecular sieve grains has a significant effect on the stability of the catalyst. ZSM-5 molecular sieves with three particle sizes A, B, and C were synthesized respectively according to the ratio and crystallization conditions in Table 1.

[0019] Molecular sieve

[0020] TPABr is tetrapropylammonium bromide.

[0021] Place 5 g of ZSM-5 molecular sieve A in 200 ml of 5 wt% NH 4 NO 3 In the solution, exchange at a temperature of 85-90°C for 2 hours, and repeat 3 times. After the exchange, the hydrogen-type ZSM-5 molecular sieve was obtained by washing and drying at 120°C. 4 grams of hydrogen-type ZSM-5 molecular sieves were mixed with 6.7 grams of 40% silica sol, and then extruded. After drying at 120°C and calcining at 400°C, catalyst A-1 was obtained. Catalyst B-1 and catalyst C-1 were prepared using molecular sieves B and C in the same manner.

[0022] Before the reaction, the catalyst was activated at 500° C. for 2 hours under a nitrog...

Embodiment 4~6

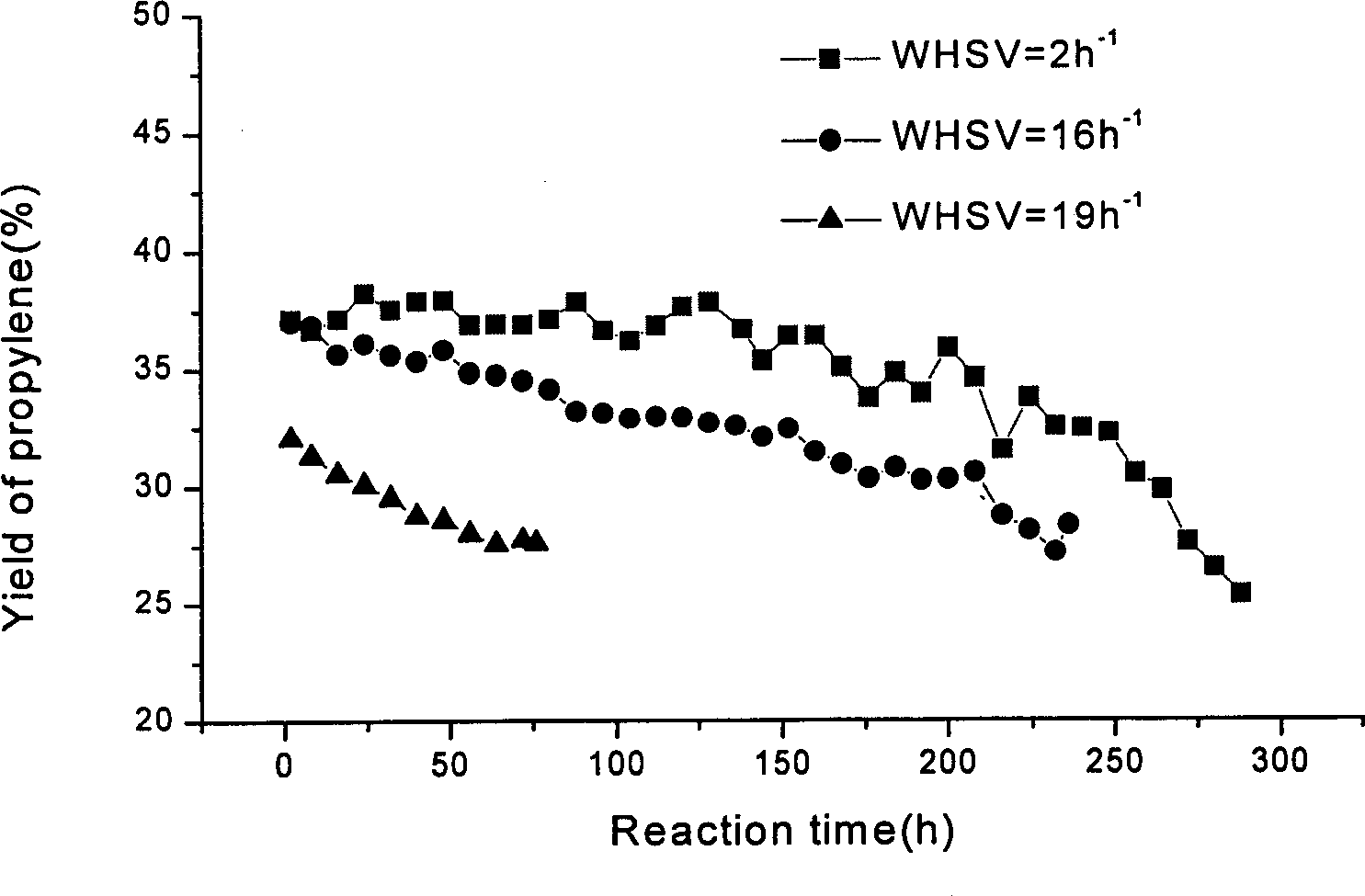

[0026] Referring to the method for preparing molecular sieve C in Table 1, change the silicon-aluminum ratio of molecular sieve, according to SiO 2 / Al 2 o 3 =450 proportioning, prepare molecular sieve D, the particle diameter of molecular sieve D is 0.5 micron, then prepare catalyst D-1 according to the same method of embodiment 1-3.

[0027] Using D-1 catalyst, using raffinate mixed carbon four as raw material, at 550°C, respectively using a weight space velocity of 2 hours -1 , 16 hours -1 , 19 hours -1 The conditions for the reaction, the results see figure 2 .

Embodiment 7

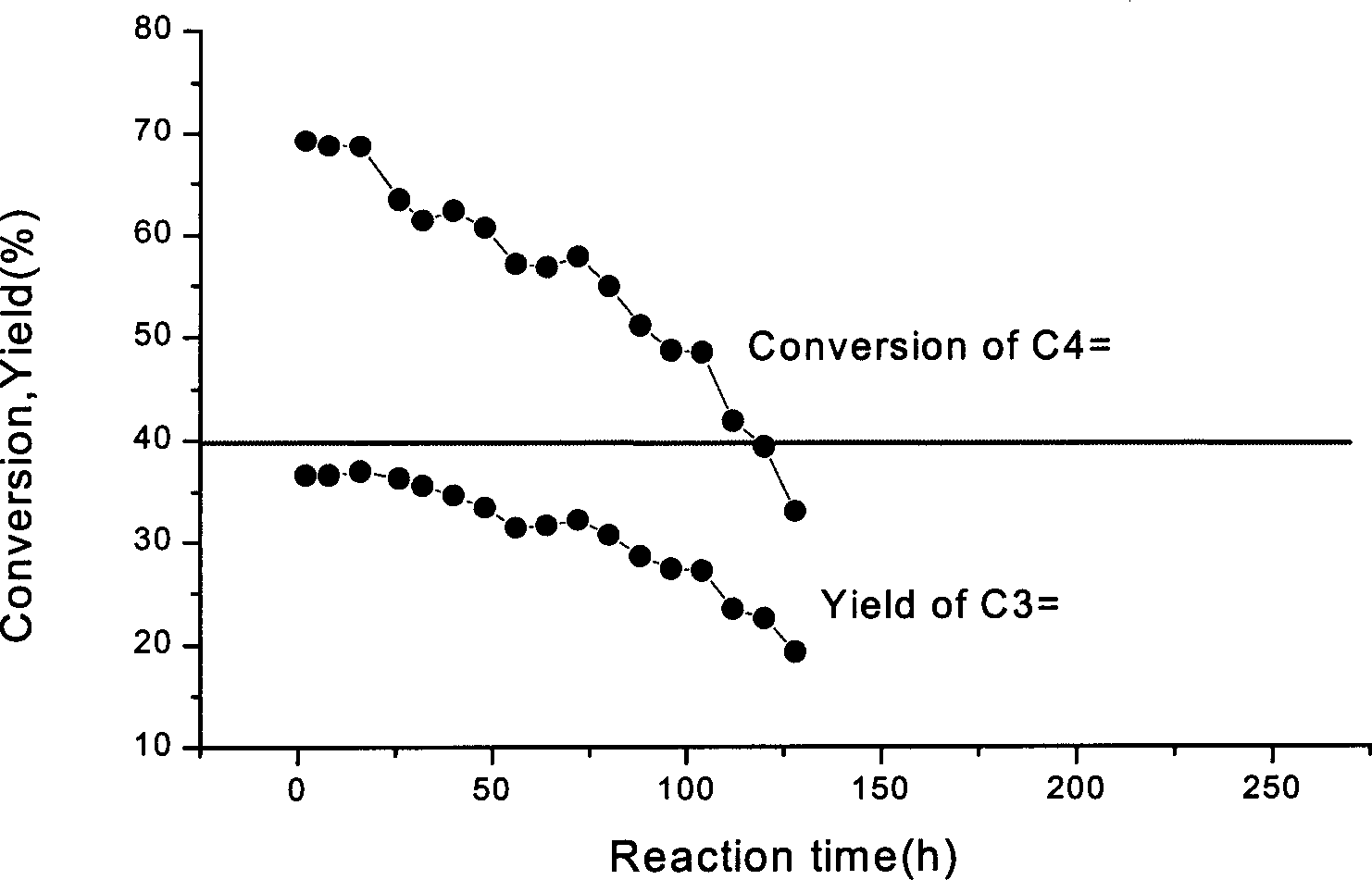

[0029] Using D-1 catalyst, using raffinate mixed carbon four as raw material, changing the reaction temperature, at 580 ° C, the weight space velocity is 16 hours -1 , the reaction was carried out under the condition of image 3 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com