Positive osmosis membrane capable of trapping ammonia nitrogen and resisting membrane pollution, preparation method and applications thereof

A forward osmosis membrane and membrane fouling technology, which is applied in chemical instruments and methods, water pollutants, semipermeable membrane separation, etc., can solve the problems of weak ammonia nitrogen interception ability and poor anti-membrane fouling ability, and improve anti-membrane fouling ability, increase hydrophilicity, and enhance the effect of membrane surface potential

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

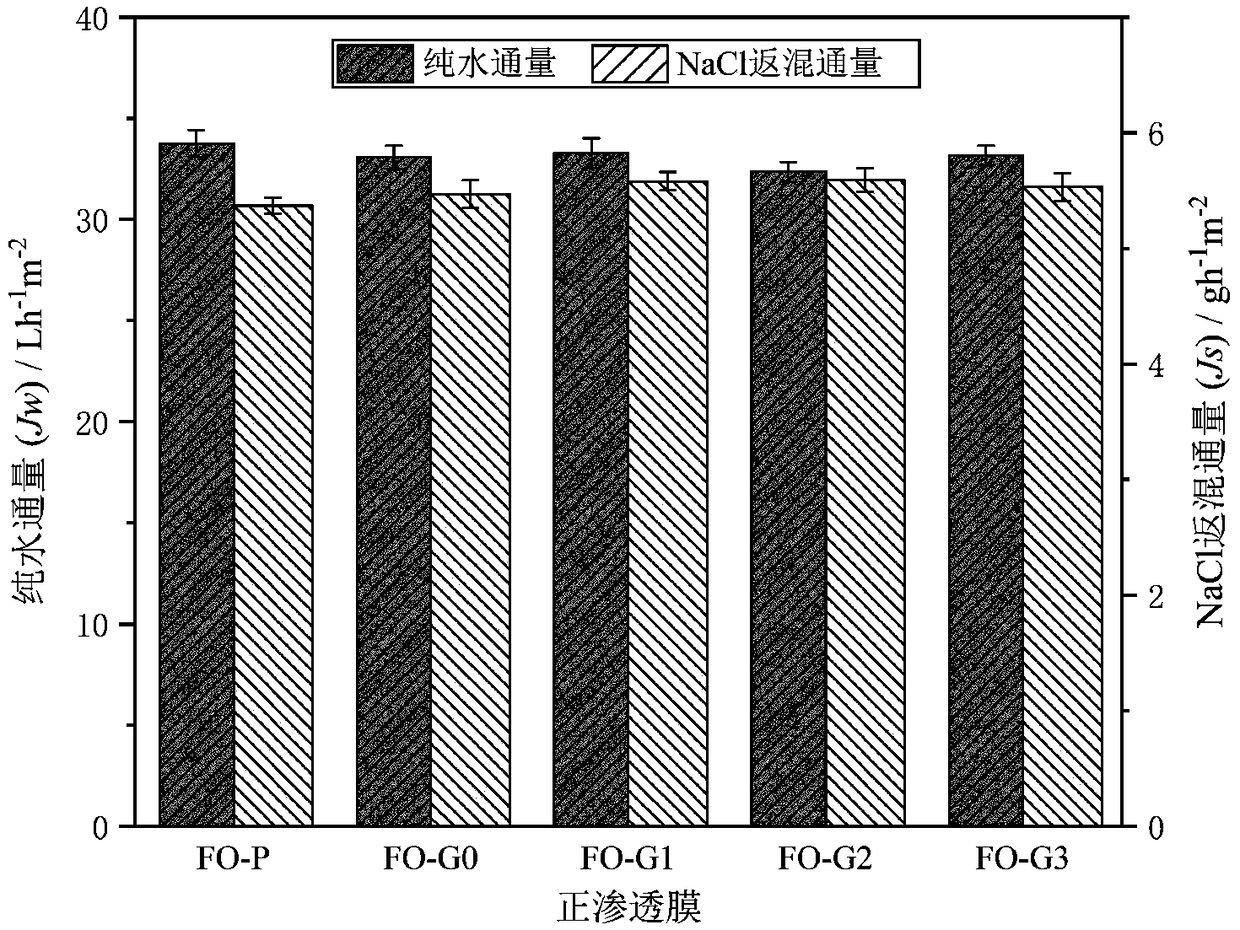

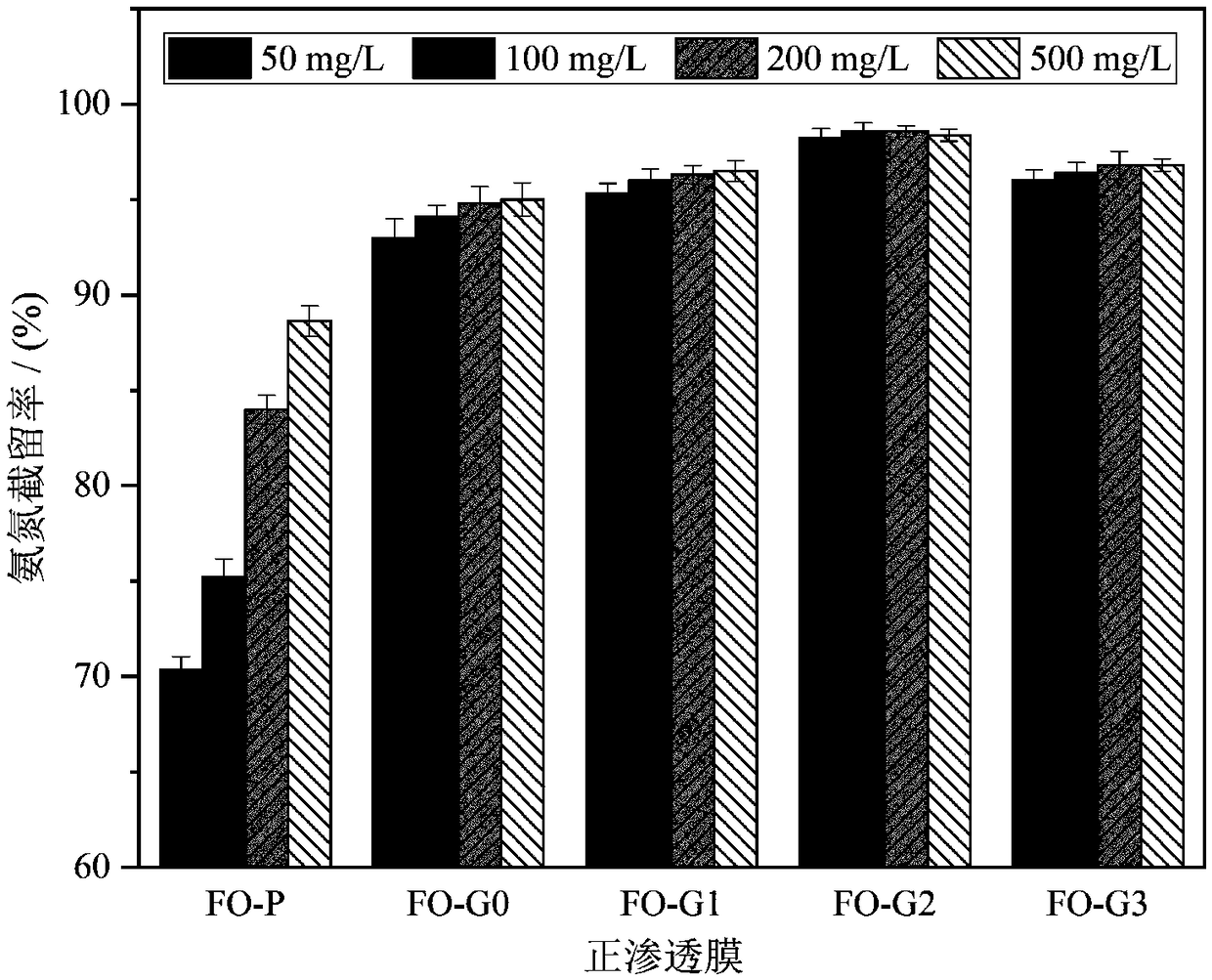

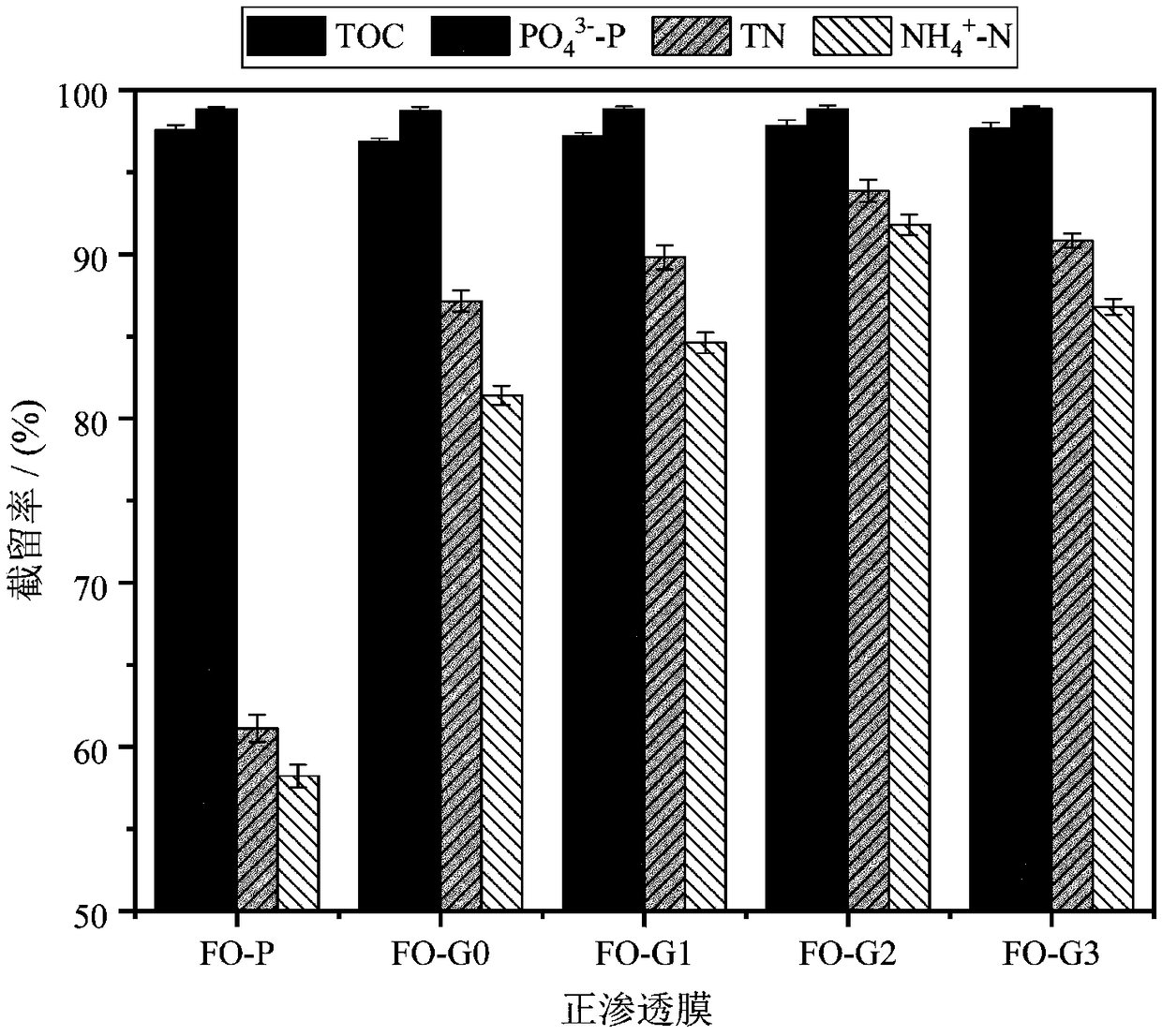

[0034]The sulfonated polyethersulfone polymer with a sulfonation degree of 1%, polyethylene glycol (Mw=600) and N,N-dimethylpyrrolidone were mixed in a weight fraction ratio of 14:10:76, sealed, heated and stirred. , After defoaming, it is prepared into a casting liquid, and the casting liquid is evenly scraped on a clean glass plate with a scraper (the height of the scraper is 100 μm). solvent. Under the operating temperature of 30°C, the upper surface of the base film was immersed in an aqueous solution of m-phenylenediamine with a mass concentration of 2%. After 2 minutes, the base film was taken out and the solution on the surface was blotted dry with filter paper, and then the obtained The upper surface of the base film continued to be immersed in the n-hexane solution of trimesoyl chloride with a mass concentration of 0.1%, the film was taken out after 1 min, and the surface of the film was rinsed with the n-hexane solution to remove unreacted trimesoyl chloride, and t...

Embodiment 2

[0037] The sulfonated polyethersulfone polymer with a sulfonation degree of 1%, polyethylene glycol (Mw=600) and N,N-dimethylpyrrolidone were mixed in a weight fraction ratio of 14:10:76, sealed, heated and stirred. , After defoaming, it is prepared into a casting liquid, and the casting liquid is evenly scraped on a clean glass plate with a scraper (the height of the scraper is 100 μm). solvent. Under the operating temperature of 30°C, the upper surface of the base film was immersed in an aqueous solution of m-phenylenediamine with a mass concentration of 2%. After 2 minutes, the base film was taken out and the solution on the surface was blotted dry with filter paper, and then the obtained The upper surface of the base film continued to be immersed in the n-hexane solution of trimesoyl chloride with a mass concentration of 0.1%, the film was taken out after 1 min, and the surface of the film was rinsed with the n-hexane solution to remove unreacted trimesoyl chloride, and ...

Embodiment 3

[0040] The sulfonated polyethersulfone polymer with a sulfonation degree of 1%, polyethylene glycol (Mw=600) and N,N-dimethylpyrrolidone were mixed in a weight fraction ratio of 14:10:76, sealed, heated and stirred. , After defoaming, it is prepared into a casting liquid, and the casting liquid is evenly scraped on a clean glass plate with a scraper (the height of the scraper is 100 μm). solvent. Under the operating temperature of 30°C, the upper surface of the base film was immersed in an aqueous solution of m-phenylenediamine with a mass concentration of 2%. After 2 minutes, the base film was taken out and the solution on the surface was blotted dry with filter paper, and then the obtained The upper surface of the base film continued to be immersed in the n-hexane solution of trimesoyl chloride with a mass concentration of 0.1%, the film was taken out after 1 min, and the surface of the film was rinsed with the n-hexane solution to remove unreacted trimesoyl chloride, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com