Negative electrode active material for lithium secondary battery, manufacturing method therefor, lithium secondary battery negative electrode comprising same, and lithium secondary battery

A negative electrode active material, lithium secondary battery technology, applied in the direction of secondary batteries, active material electrodes, battery electrodes, etc., can solve the problems of unproposed alternatives, difficult rolling, difficult to obtain density, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

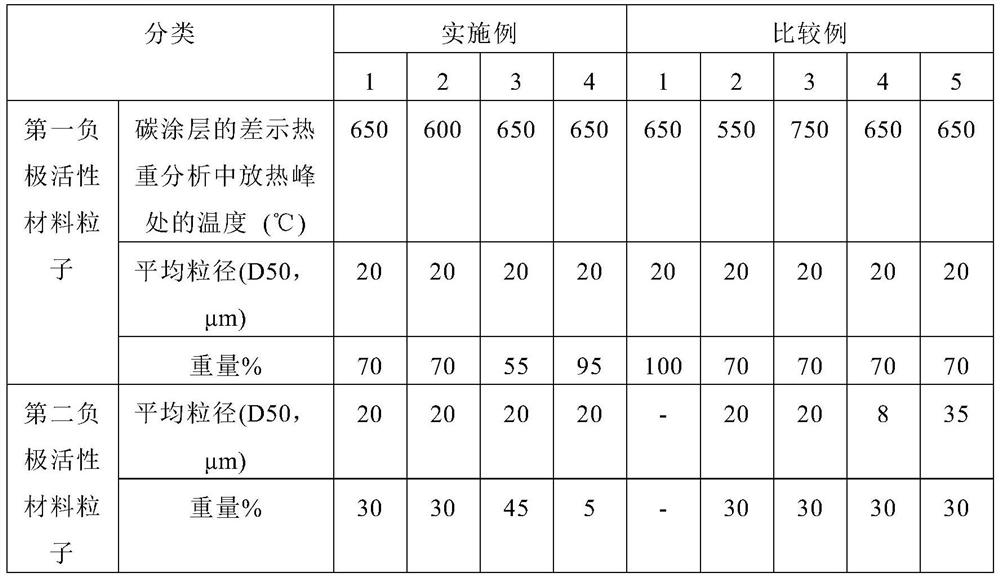

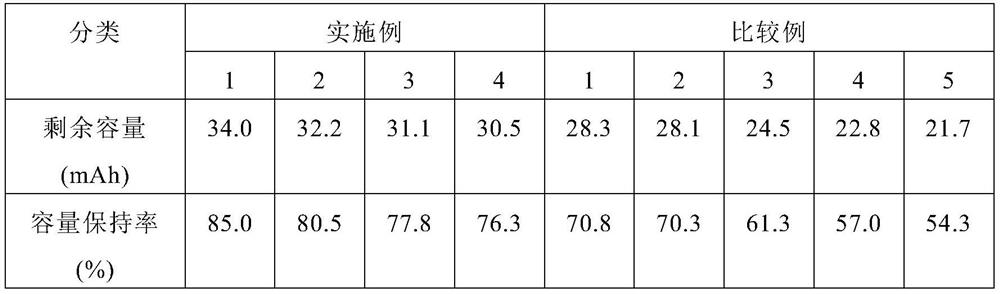

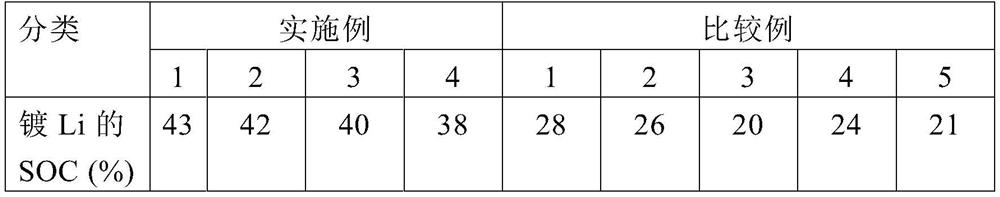

[0065] The method for preparing the negative electrode active material for lithium secondary battery of the present invention comprises the following steps: preparing first negative electrode active material particles and second negative electrode active material particles; and mixing the first negative electrode active material particles and the second negative electrode active material particles.

[0066] The step of preparing the first negative electrode active material particle includes: step a), preparing the first artificial graphite particle; and step b), mixing the first artificial graphite particle with the material for forming the carbon coating, and subjecting the mixture to a second heat treatment , to form a carbon coating including hard carbon on the first artificial graphite particles, the carbon coating forming material includes a carbon-based material formed by the first heat treatment and a polymer for controlling crystallinity.

[0067] The average particle d...

Embodiment 1

[0113] Embodiment 1: Preparation of negative electrode active material for lithium secondary battery

[0114] Preparation of the first negative electrode active material particles

[0115] A coking process is performed in which petroleum pitch, which is a by-product generated after oil extraction, is calcined at 1500° C. to form needle coke-based artificial graphite, and the needle coke-based artificial graphite is heated at 3000° C. The heat treatment was carried out for more than 1 hour to prepare graphitized primary artificial graphite particles with an average particle diameter of 10 μm.

[0116] Subsequently, the primary artificial graphite particles were mixed with a mixture containing, as a material for carbon coating formation, petroleum pitch subjected to a primary heat treatment at 1150° C. Polyacrylic acid is a crystallinity controlled polymer. Polyvinylidene fluoride (PVDF) as a binder for carbon coating formation was added to the resulting mixture. The primary ...

Embodiment 2

[0123] Embodiment 2: Preparation of negative electrode active material for lithium secondary battery

[0124] In addition to using a mixture containing petroleum pitch subjected to the first heat treatment at 900° C. as a material for carbon coating formation and polyacrylic acid as a polymer for controlling crystallinity in a weight ratio of 50:50, in the same manner as in the implementation The same way in Example 1 prepares average particle diameter D 50 The first negative electrode active material particle is 20 μm.

[0125] Next, the first negative electrode active material particles and the second negative electrode active material particles prepared in Example 1 were mixed in a weight ratio of 70:30, and mixed using a TK mixer to prepare the negative active material particles of Example 2. Material.

[0126] In the thus prepared first anode active material particle in Example 2, the temperature at the exothermic peak in the differential thermogravimetric analysis of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com