Compound enzyme preparation, tobacco lamina treatment method, material adding and storage method and penetration inspection method

A technology of compound enzyme preparation and treatment method, which is applied in the field of tobacco leaf preparation and can solve the problems of poor absorption effect and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

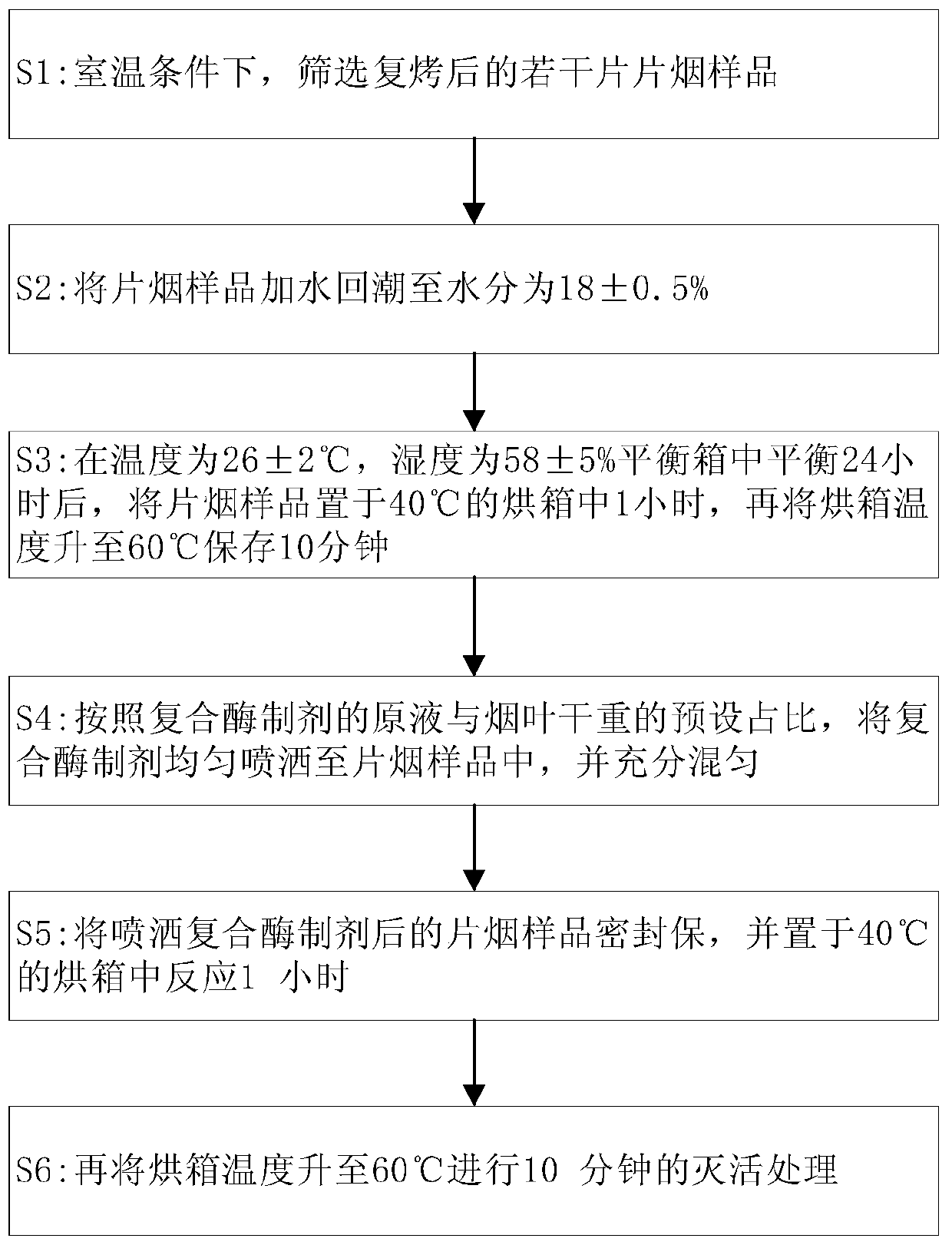

[0038] In order to enable those skilled in the art to further understand the features and technical contents of the present invention, the embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings and implementation methods.

[0039] Before the scheme of the present invention is described, also need to do following introduction to the existing situation of this field:

[0040] In the field of cigarettes, there are several common methods to improve the absorption effect of sheet cigarettes on tobacco feed liquid: In the sheet tobacco feeding process: by increasing the temperature of the feed liquid, reducing the particle size of the feed liquid components, increasing the feed liquid The degree of diffusion on the surface of the tobacco sheet promotes the absorption effect of the tobacco sheet on the feed liquid; in addition, it can also prolong the storage time under the condition of the production cost to increase the a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com