Plate surface laminating device for aluminum-plastic plate machining

A coating device and a technology for aluminum-plastic panels, which are applied in the field of surface coating devices for aluminum-plastic panel processing, can solve problems affecting the quality of aluminum-plastic panel coatings, waste of raw materials, and glue collection and treatment, and increase the uniformity of coating , Improving the quality of the coating and preventing the glue from curing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

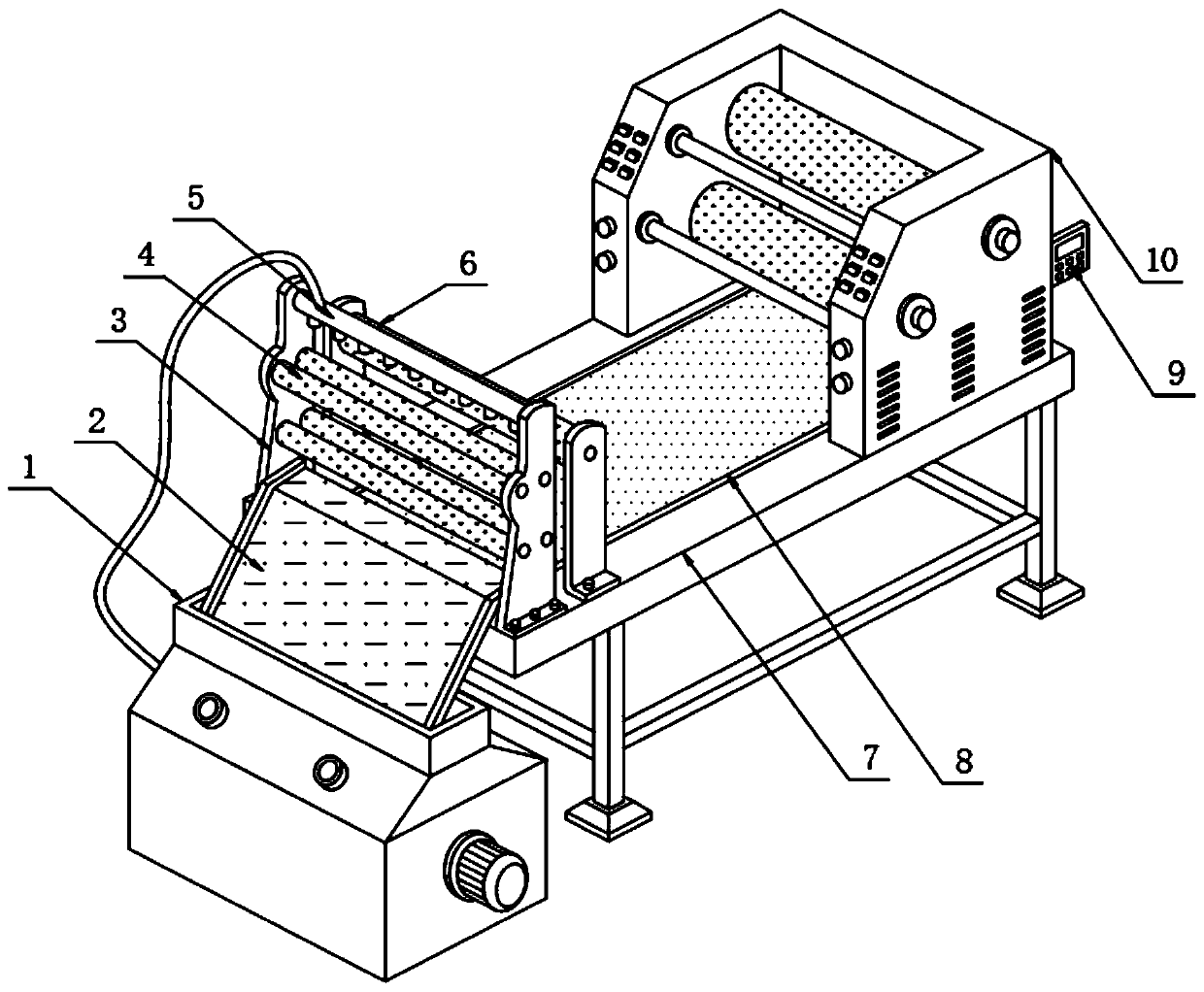

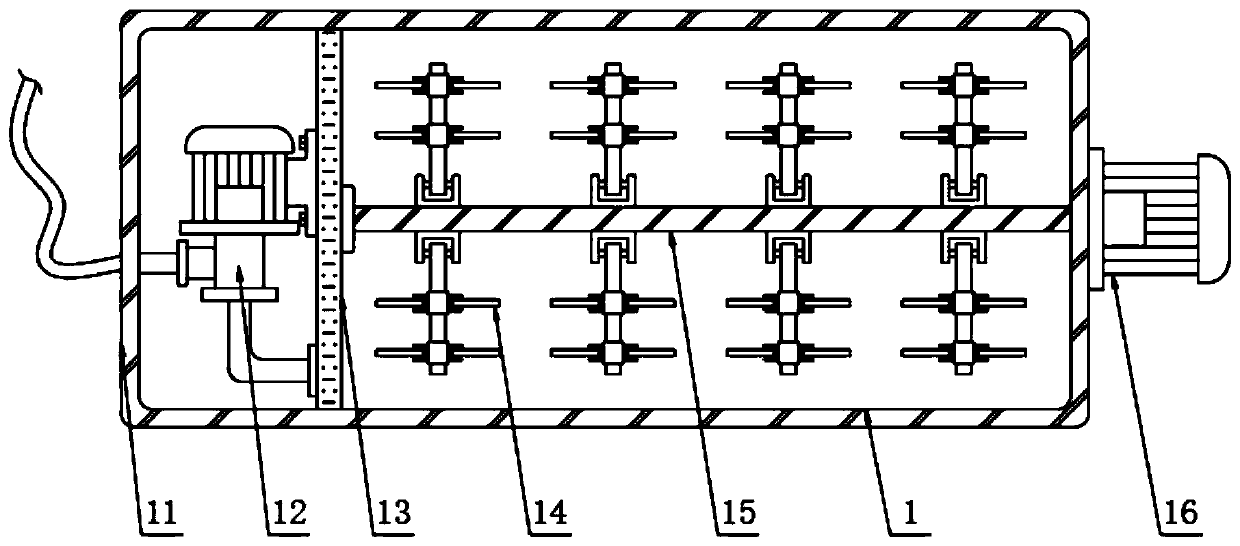

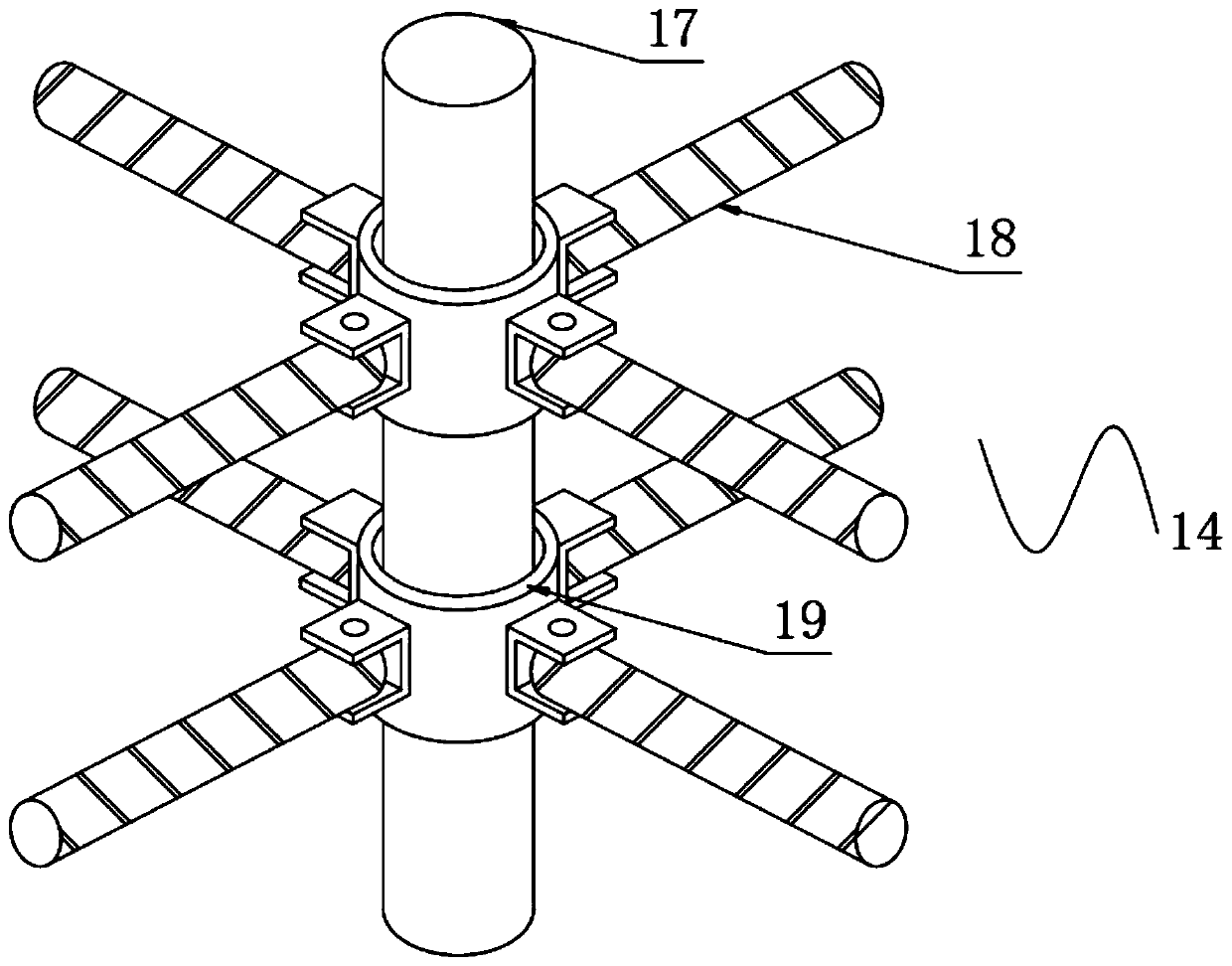

[0022] see Figures 1 to 5 , In the embodiment of the present invention, a plate surface laminating device for aluminum-plastic panel processing includes a conveying platform 7, a processing platform 10 fixed on the upper surface of the conveying platform 7 by the rear and front, and a paper roll 6 and a roller 6 arranged on the conveying platform The conveyor belt 8 at the center of the upper surface of the platform 7, the rear surface of the processing table 10 is fixed with a control switch 9 and a battery, the inside of the control switch 9 is installed with a DKC-Y110 controller, and the edge of the upper surface of the conveying platform 7 is also fixed. There are a first installation bracket 3 and a second installation bracket 24. The connection between the first installation bracket 3 and the second installation bracket 24 is sequentially provided with a conveying pipe 5 and a gluing assembly 4 from top to bottom. The gluing assembly 4 includes a second The motor 20, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com