Anti-curing brush coating device and brush coating method

A technology of brushing glue and conveying device, which is applied to devices and coatings that apply liquid to the surface, can solve the problems that the uniformity of application is difficult to guarantee, the quality of shoes is affected, and the glue is easy to cure. Good smearing uniformity, not easy to cure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

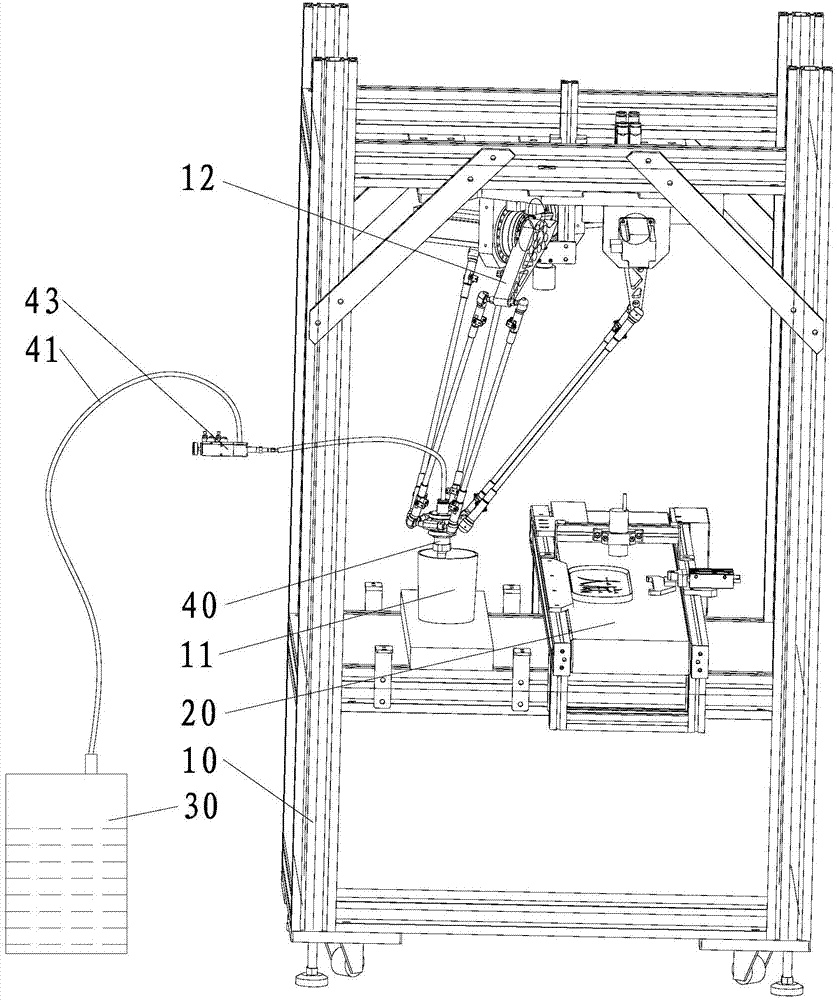

[0033] like figure 1 and figure 2 As shown, the anti-curing glue brushing device provided in this embodiment includes a bracket 10, a conveying device 20 pierced in the frame 10, and a glue tank 30 positioned outside the frame, wherein the conveying device 20 can be a conventional device, mainly It is not the focus of this embodiment to transport the workpiece to be glued, so it will not be described in detail here. It should be noted that, in this embodiment, the sole of a vulcanized shoe is used as an example for description.

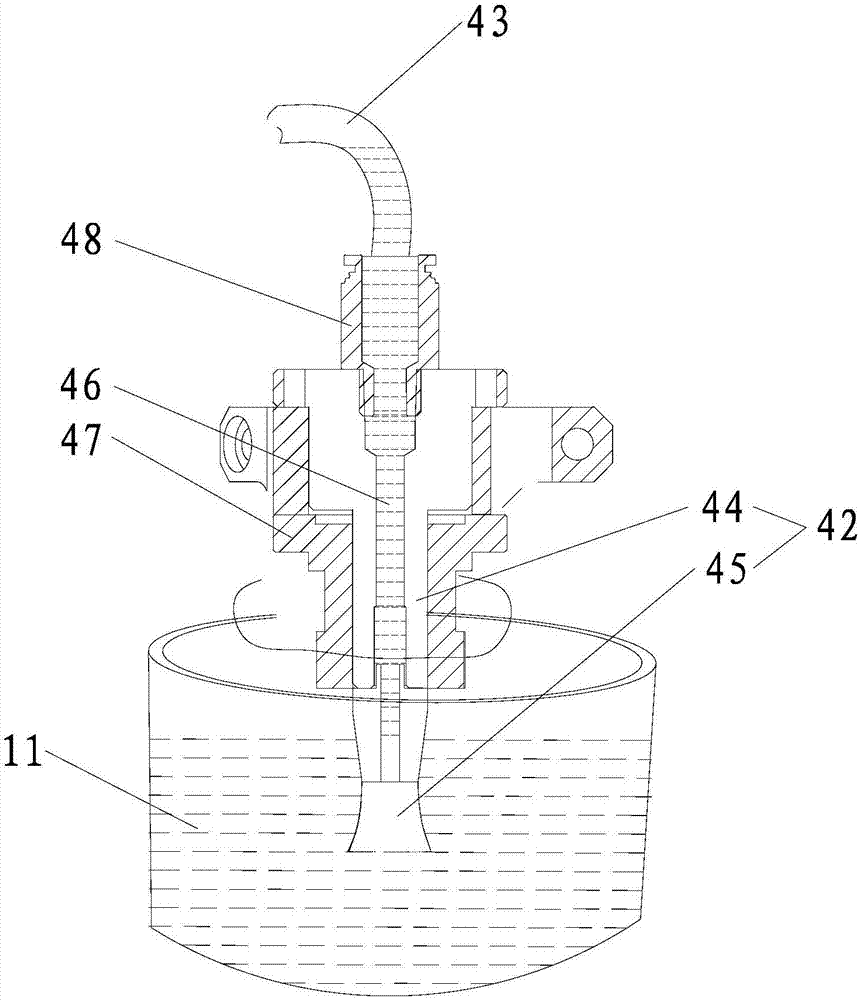

[0034] The frame 10 is provided with a glue cup 11 at a position beside the conveying device 20 , and the bottom surface of the glue cup 11 is preferably on the same level as the conveying surface of the conveying device 20 . Simultaneously, the frame 10 is provided with a manipulator 12 at a position above the con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com