Injection moulding method of membrane inside mould

A technology of injection molding and diaphragm, applied in the direction of coating, etc., can solve the problems of reduced product yield, poor rigidity of diaphragm F1, deviation of diaphragm F1, etc., to achieve the effect of improving yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

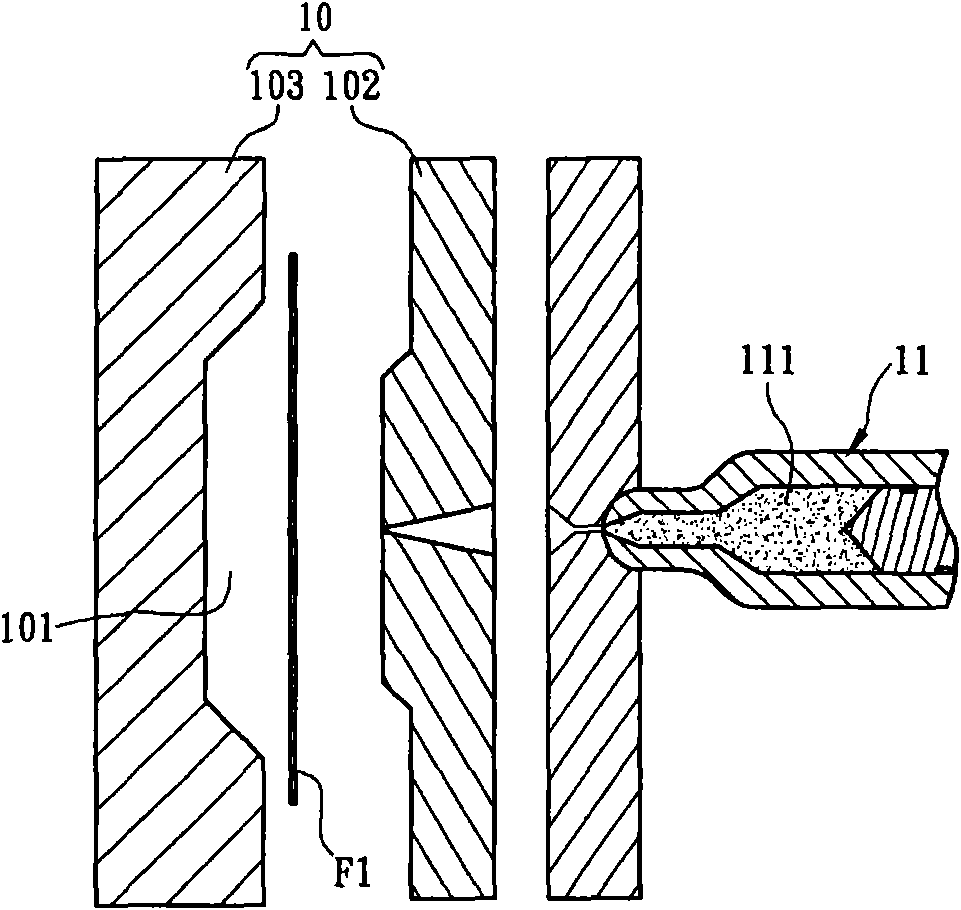

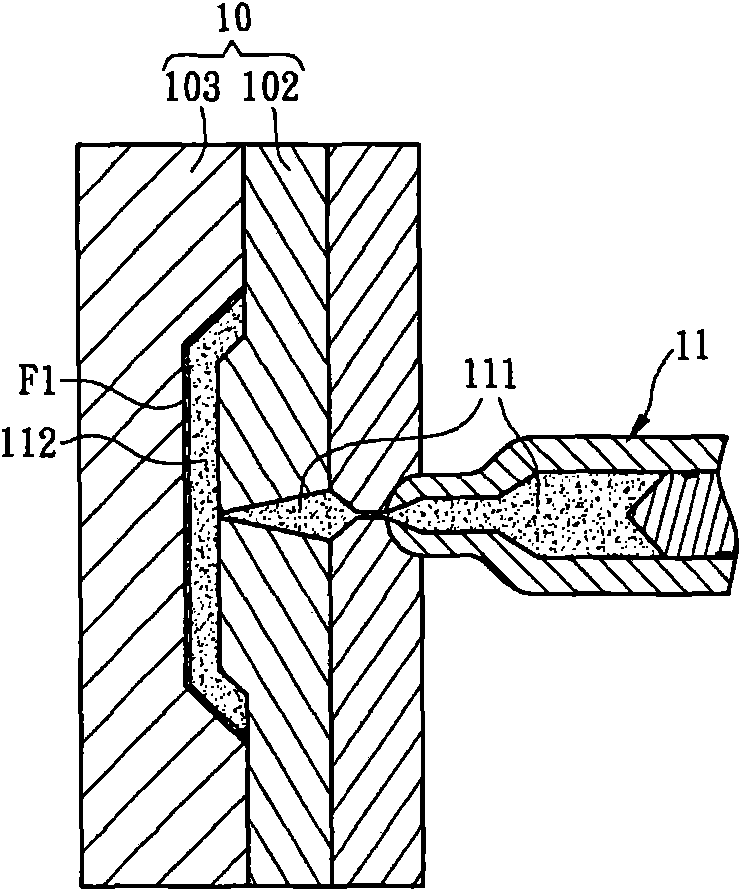

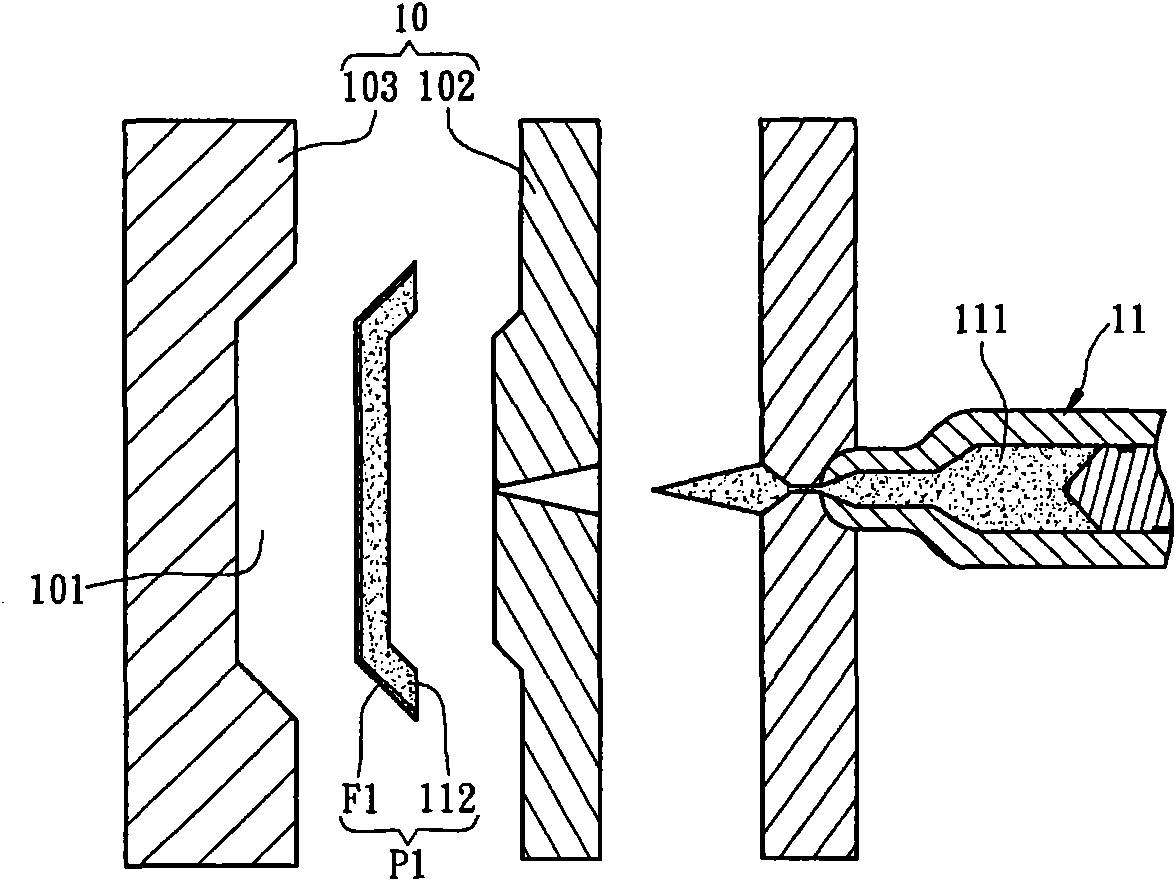

[0012] A method and molded product of an in-mold film injection molding according to a preferred embodiment of the present invention will be described below with reference to related drawings, wherein the same components will be described with the same reference symbols.

[0013] image 3 It is a flow chart of a method for injection molding of an in-mold film (IMF) (hereinafter referred to as the molding method) according to a preferred embodiment of the present invention, which includes steps S01 to S06, Figure 4A to Figure 4D A schematic diagram of the molding method. Please refer to the following Figure 4A to Figure 4D and match image 3 To illustrate the molding method.

[0014] First, step S01 is to provide a film F2 with a predetermined pattern. The present invention does not limit the types of preset patterns, which can be changed according to actual needs. The predetermined pattern can be formed on at least one surface of the film F2, and can be formed on the su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com