Discrete air film cooling hole shape

A film cooling and hole pattern technology, which is applied to the support elements of blades, engine elements, machines/engines, etc., and can solve the problems of poor structural strength and difficult hole pattern processing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

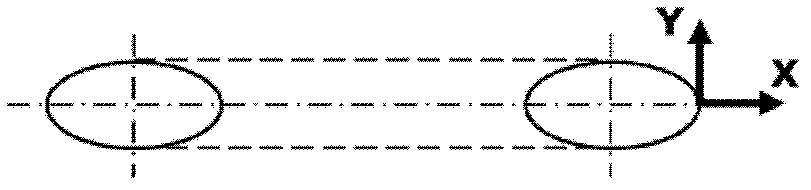

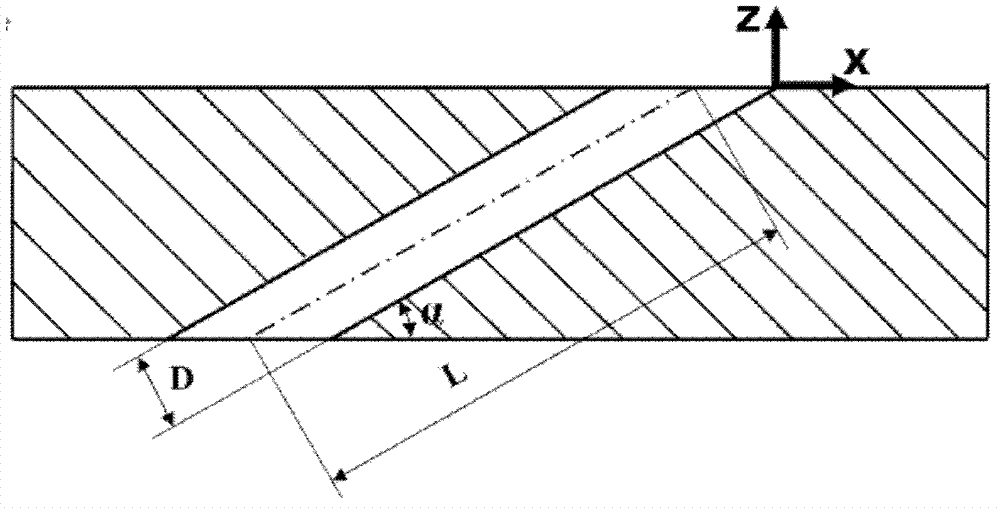

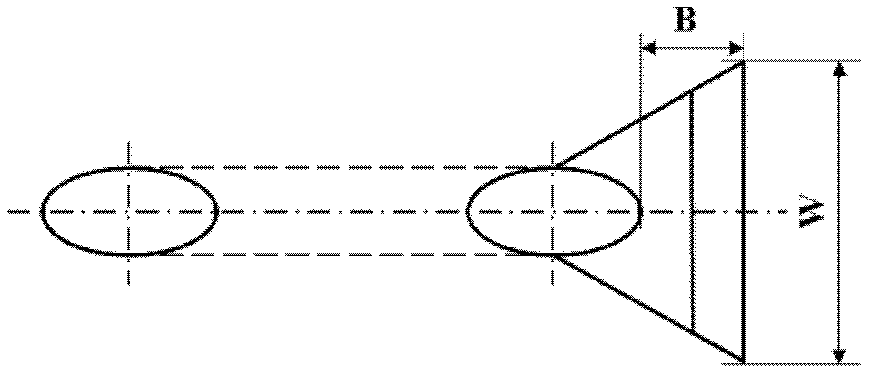

[0038] Figure 1a-1 , Figure 1a-2 It is the original ordinary cylindrical hole structure, and the length, diameter, and injection angle of the ordinary cylindrical hole are represented by L, D, and α, respectively. Coordinates X, Y, Z represent flow direction, transverse direction and radial direction respectively. Figure 1b-1 It is the basic form of a kind of discrete air film cooling hole type of the present invention, which is to Figure 1a-1 The subsidence and expansion treatment of the outlet of ordinary cylindrical holes, the subsidence depth, expansion length, and expansion width of the hole pattern are represented by H, B, and W respectively, and the angle of the gas outlet side of the subsidence structure is represented by β. Figure 1c-1 It is an evolution form of a discrete film cooling hole type of the present invention. On the basis of the basic form, an internal expansion boss structure is added between the downstream of the air outlet side of the cylindrical h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com