Disperse air film cooling hole structure

A technology of air film cooling and cooling holes, which is applied to the supporting elements of blades, engine elements, machines/engines, etc., to achieve the effect of expanding the outlet width, enhancing the adhesion ability of the air film, and having a high cooling effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with specific embodiments and with reference to the accompanying drawings.

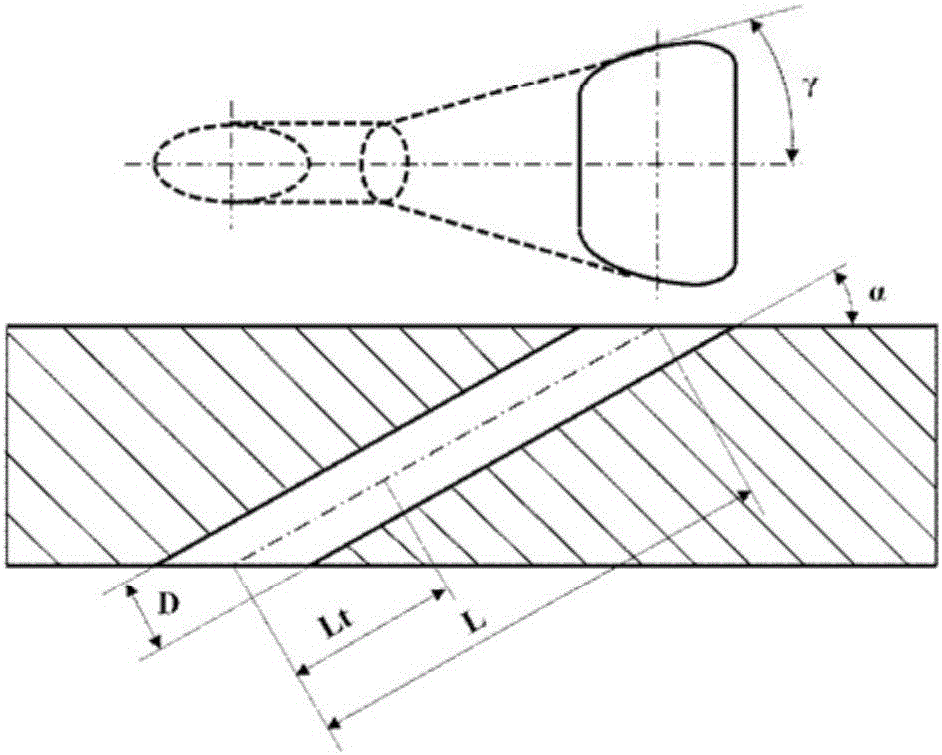

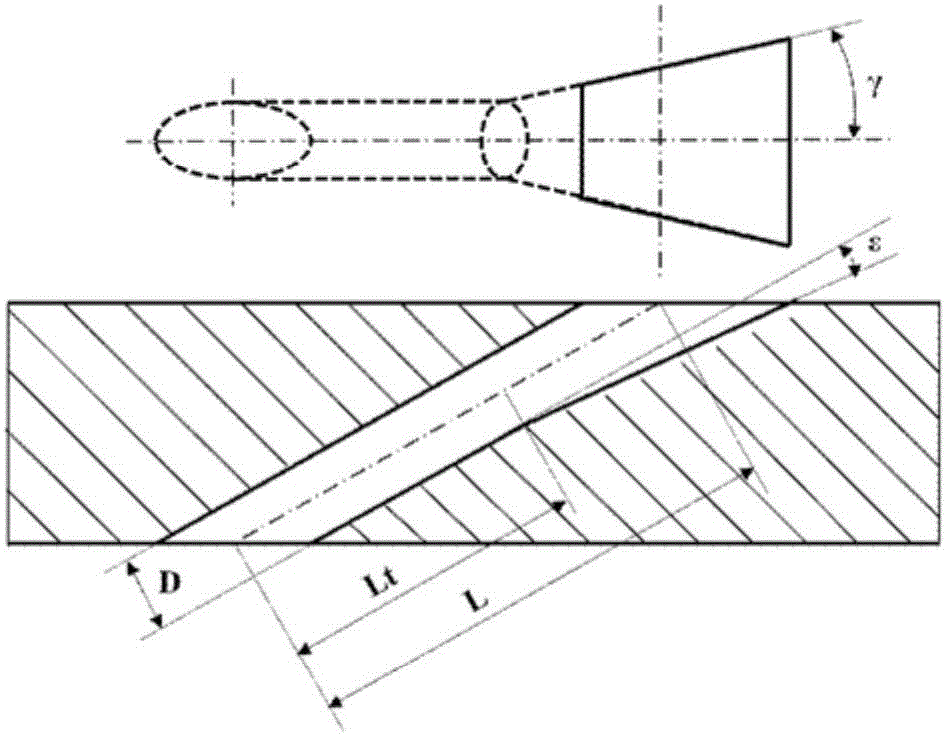

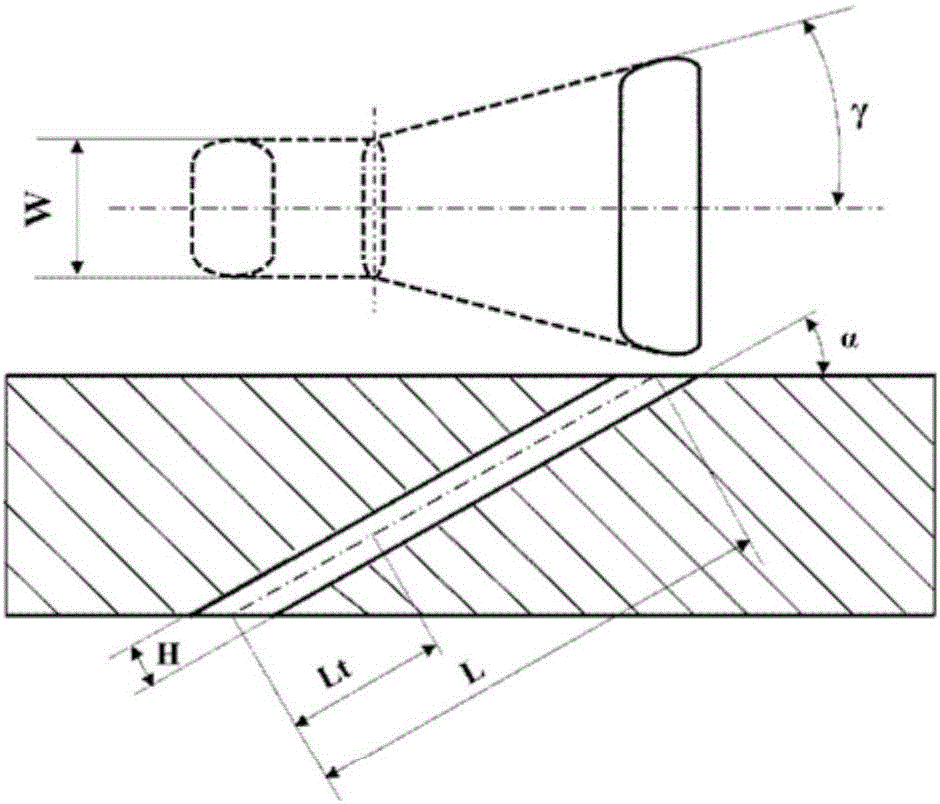

[0038] Figure 1a and Figure 1b The structures of the existing fan-shaped and dustpan-shaped expansion holes are respectively shown, which are the two most widely used cooling holes at present, and the cooling effect of the simple cylindrical hole is greatly improved. Both holes are expansion holes, that is, the first half of the cooling hole is a cylindrical hole, and the second half of the cooling hole is an expansion structure, including lateral expansion and front expansion. The length of the straight section of the hole is represented by Lt, the total length of the hole is represented by L, the lateral expansion angle is represented by γ, and the front expansion angle is represented by ε. Apparently, the two existi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com