Fibrous scaffold, and preparation method and application thereof

A fiber scaffold and fiber technology, applied in the field of bioengineering, can solve the problems of small gaps, acid, alkali and high temperature resistance, etc., and achieve the effect of simple steps, high mechanical strength and large gaps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

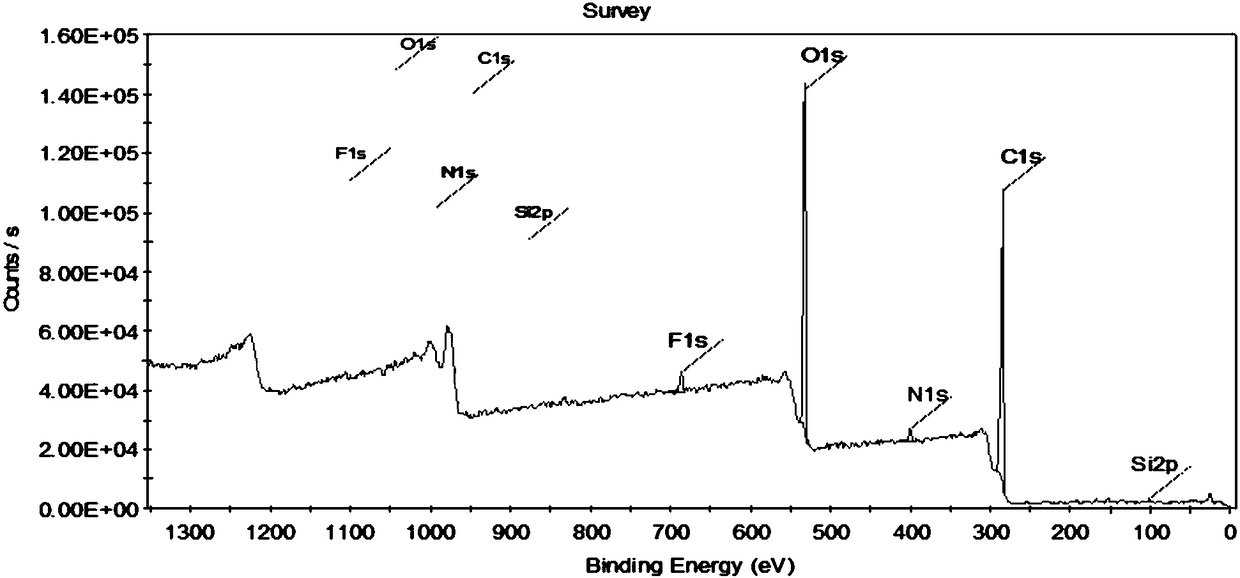

Image

Examples

preparation example Construction

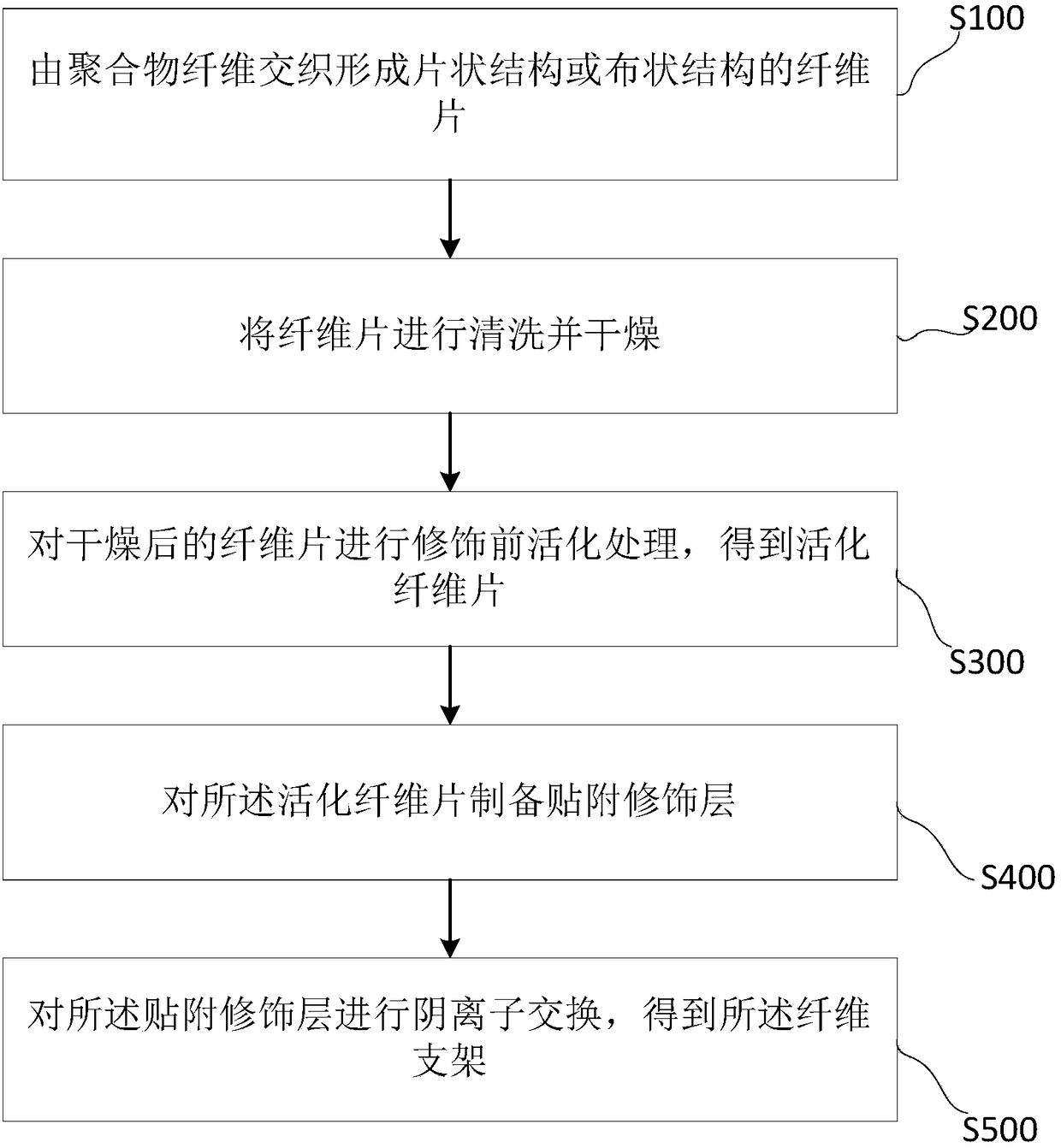

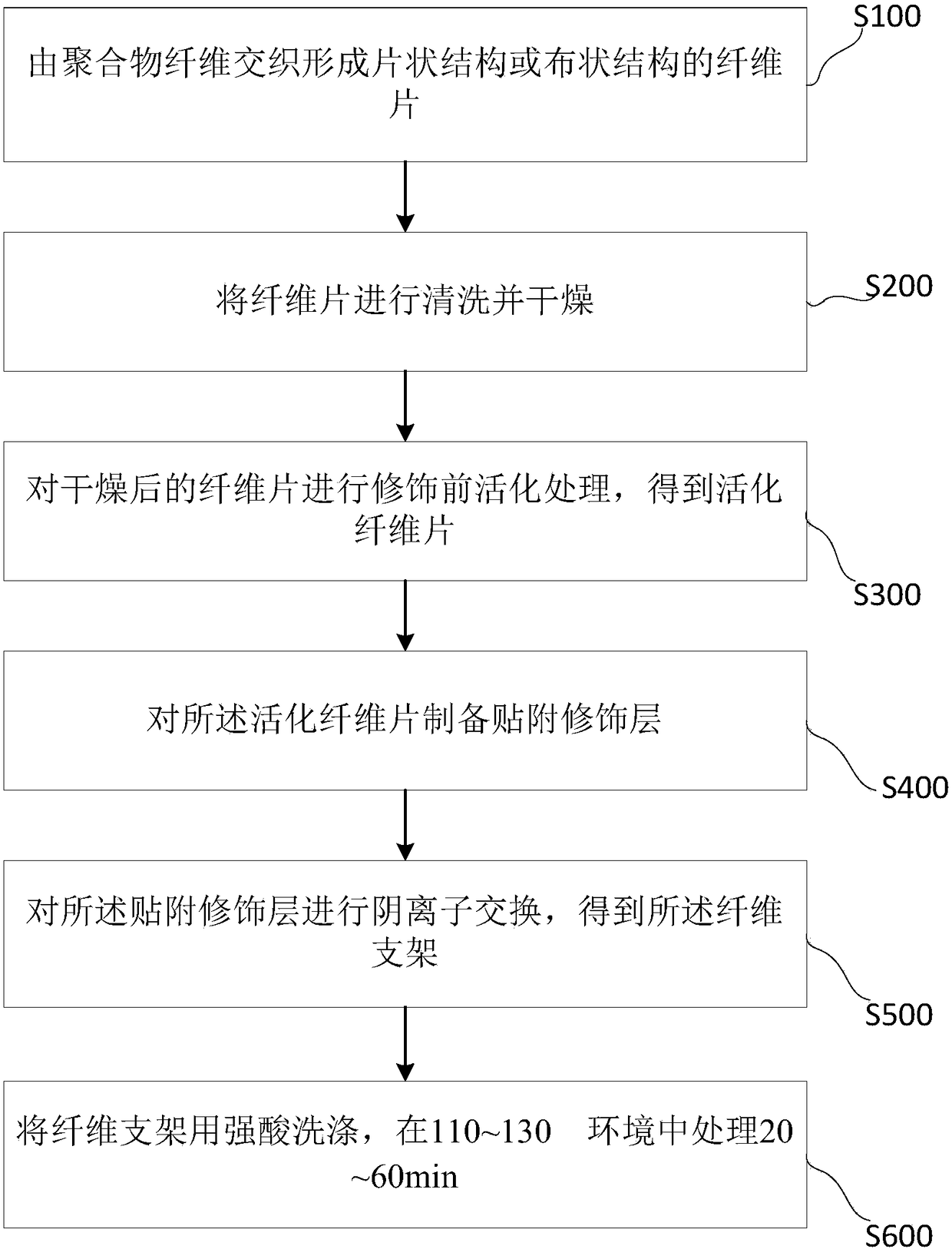

[0047] Such as figure 1Shown, the preparation method of fiber scaffold comprises:

[0048] S100: A fiber sheet made of polymer fibers interwoven to form a sheet-like structure or a cloth-like structure

[0049] S200: Washing and drying the fiber sheet.

[0050] Preferably, double-distilled water or even ultrapure water is used for cleaning, and ultrasonic cleaning can be used for cleaning, and the cleaning time is 15 to 35 minutes. The drying method can be carried out in an oven at 60-80°C or a similar environment.

[0051] Preferably, step S100 further includes the step of soaking the fiber sheet with 20-30% hydrogen peroxide. The concentration of the hydrogen peroxide solution is preferably 20% to 30%, and the soaking time can be 3 to 6 hours when the temperature is 65 to 80°C.

[0052] S300: Perform pre-modification activation treatment on the dried fiber sheet to obtain an activated fiber sheet.

[0053] Specifically, the fiber sheet is added to an activator with a co...

Embodiment 1

[0067] Fibrous scaffolds and their preparation

[0068] The polymer fibers made of polyester carbonate are interwoven to form a sheet-like fiber sheet, which undergoes the following series of treatments:

[0069] Cleaning pretreatment: add the fiber sheets to ultrapure water, use ultrasonic cleaning for 20 minutes, then blow dry with nitrogen, soak in 25% hydrogen peroxide solution at 65°C for 4 hours, and then use ultrapure water to ultrasonically Wash for 30 minutes and dry in a drying oven at 75°C for use.

[0070] Fiber sheet activation catalysis: the fiber sheet that pretreatment obtains is added to the bis-epoxidized butadiene that concentration is 5mmol / g, n-butyl glycidyl ether mixture (the mol ratio of bis-epoxidized butadiene and n-butyl glycidyl ether is 1:1), the temperature for activating the catalyst was 50°C, after 18 hours, it was taken out and cleaned ultrasonically with ultrapure water for 30 minutes, and then dried with nitrogen to obtain an activated fiber...

Embodiment 2

[0075] Fibrous scaffolds and their preparation

[0076] The polymer fibers made of polypropylene are interwoven to form a sheet-like fiber sheet, which undergoes the following series of treatments:

[0077] Cleaning pretreatment: Add the fiber sheets to ultrapure water, use ultrasonic cleaning for 15 minutes, then blow dry with nitrogen, soak in 30% hydrogen peroxide solution at 70°C for 3 hours, and then use ultrapure water to ultrasonically Wash for 30 minutes and dry in a drying oven at 75°C for use.

[0078] Activation and catalysis of fiber sheets: add the pretreated fiber sheets to bis-epoxidized butadiene with a concentration of 2mmol / g, and activate the catalyst at a temperature of 45°C. After 24 hours, take them out and ultrasonically clean them with ultrapure water for 30 minutes, and then use Blow dry with nitrogen to obtain an activated fiber sheet.

[0079] Attachment modification: Dissolve lysine in 0.5mol / L KOH solution, prepare it into a lysine alkali solutio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com